Method for drying oil-tea camellia seed

A drying method and technology of camellia oleifera seeds, which are applied in the directions of drying solid materials, heating to dry solid materials, drying, etc., can solve the problems of being unsuitable for large-scale industrial production, poor storage quality of camellia oleifera seeds, and long drying time, and achieve Ease of control, reduced refining process, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] The freshly harvested Camellia oleifera fruits are selected to remove impurities, moldy and pest-damaged Camellia oleifera fruits. The selected Camellia oleifera fruits were placed at room temperature, and the relative humidity was controlled at 75%. After 10 days of stack retting, the oil content of Camellia oleifera seeds was significantly increased, and the shells of Camellia oleifera seeds could be easily removed after stack retting. Camellia oleifera seeds are dried with hot air, and the camellia oleifera seeds are dried at a temperature of 55°C and a bulk density of 320kg / m 3 Lay flat, and dry for 15 hours, so that the water content of the camellia seed reaches below 10%. The dried camellia seeds were stored at room temperature for 8 months, and the acid value and peroxide value of oil in the camellia seeds after storage for 8 months increased by 0.34mgKOH / g and 0.86mmol / kg respectively compared with the initial storage , indicating that the oil content of camell...

Embodiment 2

[0020] The freshly harvested Camellia oleifera fruit is selected to remove the impurities mixed in the Camellia oleifera fruit, the moldy and the Camellia oleifera fruit that is damaged by diseases and insect pests. The selected camellia oleifera fruit is placed at room temperature, the relative humidity is controlled to be 75%, no stack retting or stack retting treatment respectively for 2, 4, 6, 10, 12, 14 days, other process conditions are the same as in Example 1. See Table 1 for the results of oil content improvement of Camellia oleifera seeds.

[0021] Table 1 Changes of main components in Camellia oleifera seeds treated with different retting times

[0022] Retting days (d)

Embodiment 3

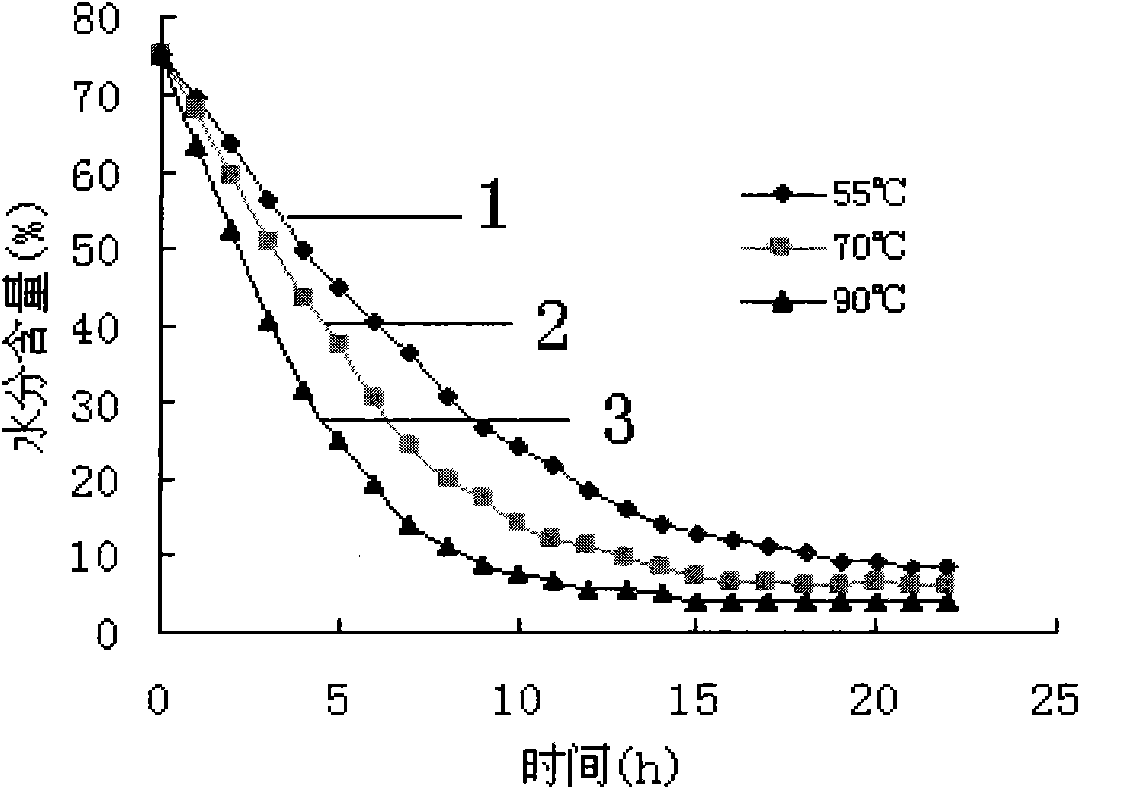

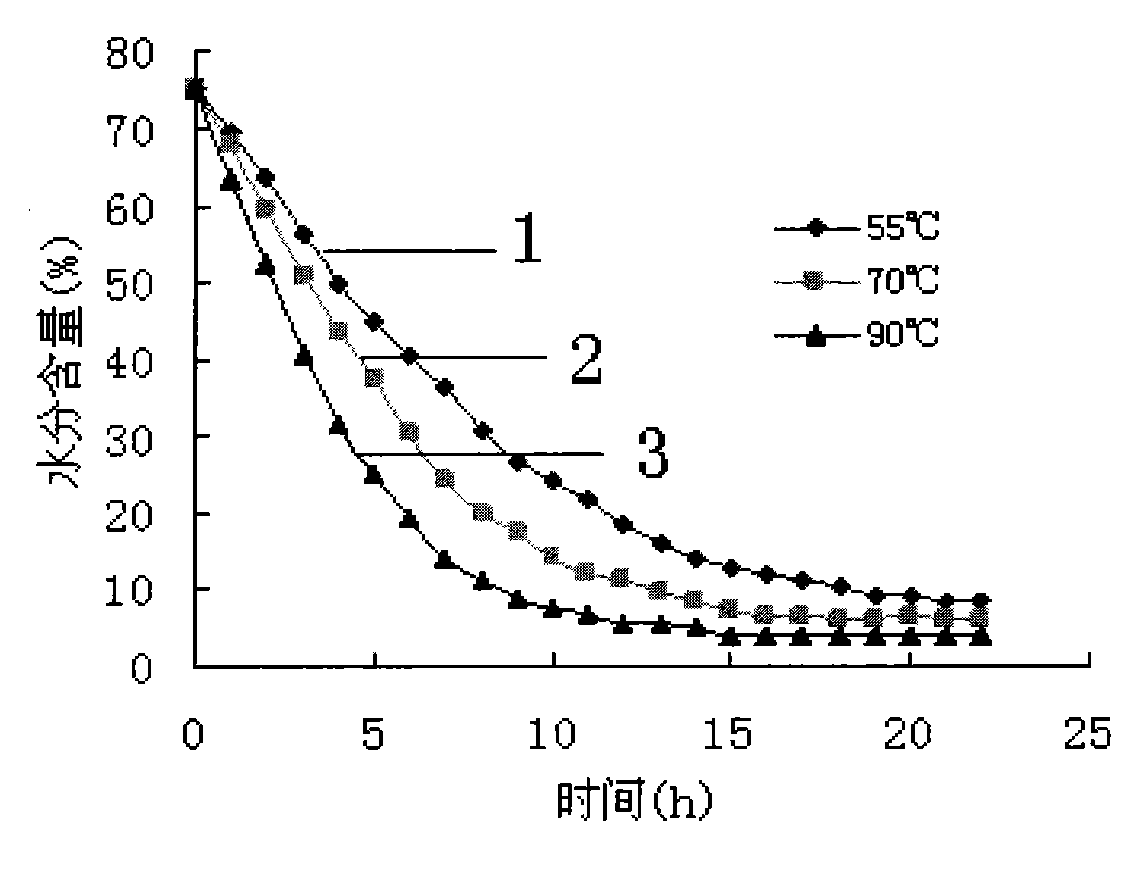

[0024] The freshly harvested camellia oleifera fruit is selected to remove impurities, moldy and pest-damaged camellia oleifera fruit. Place it at room temperature, control the relative humidity to be 75%, stack retting for 12 days, and remove the camellia oleifera husk. Different temperatures are used for hot air drying, and the bulk density is 320kg / m 3 Lay flat, dry for 13 hours, measure the relationship between drying temperature and water content, see attached figure 1 shown. attached figure 1 Among them, curves 1, 2, and 3 are the experimental results under the temperature conditions of 55°C, 70°C, and 90°C, respectively.

[0025] attached by figure 1 It can be seen that the water content of camellia oleifera seeds decreased rapidly with the extension of drying time in the early stage of drying, and the water content decreased slowly in the later stage of drying. The higher the drying temperature, the faster the moisture content of camellia oleifera seeds will decre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com