Chromatograph on-line analysis method for source rock by closed ball milling, heating analysis and cold trap trapping

A technology of heating analysis and analysis method, which is applied in the field of online extraction and analysis of various hydrocarbon contents, can solve the problem of excessive component loss, and achieve the effect of reducing loss, avoiding loss and avoiding oxidation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

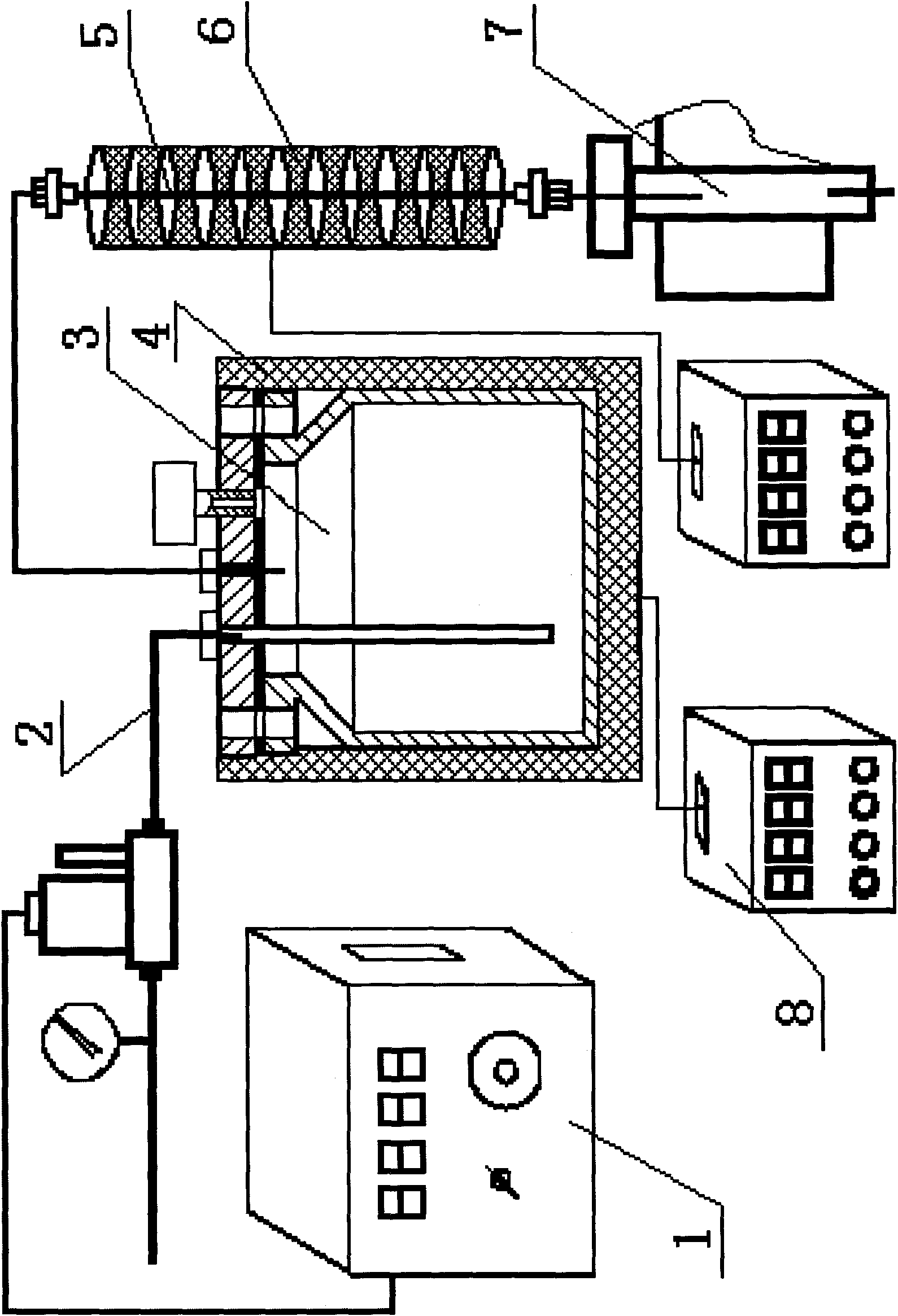

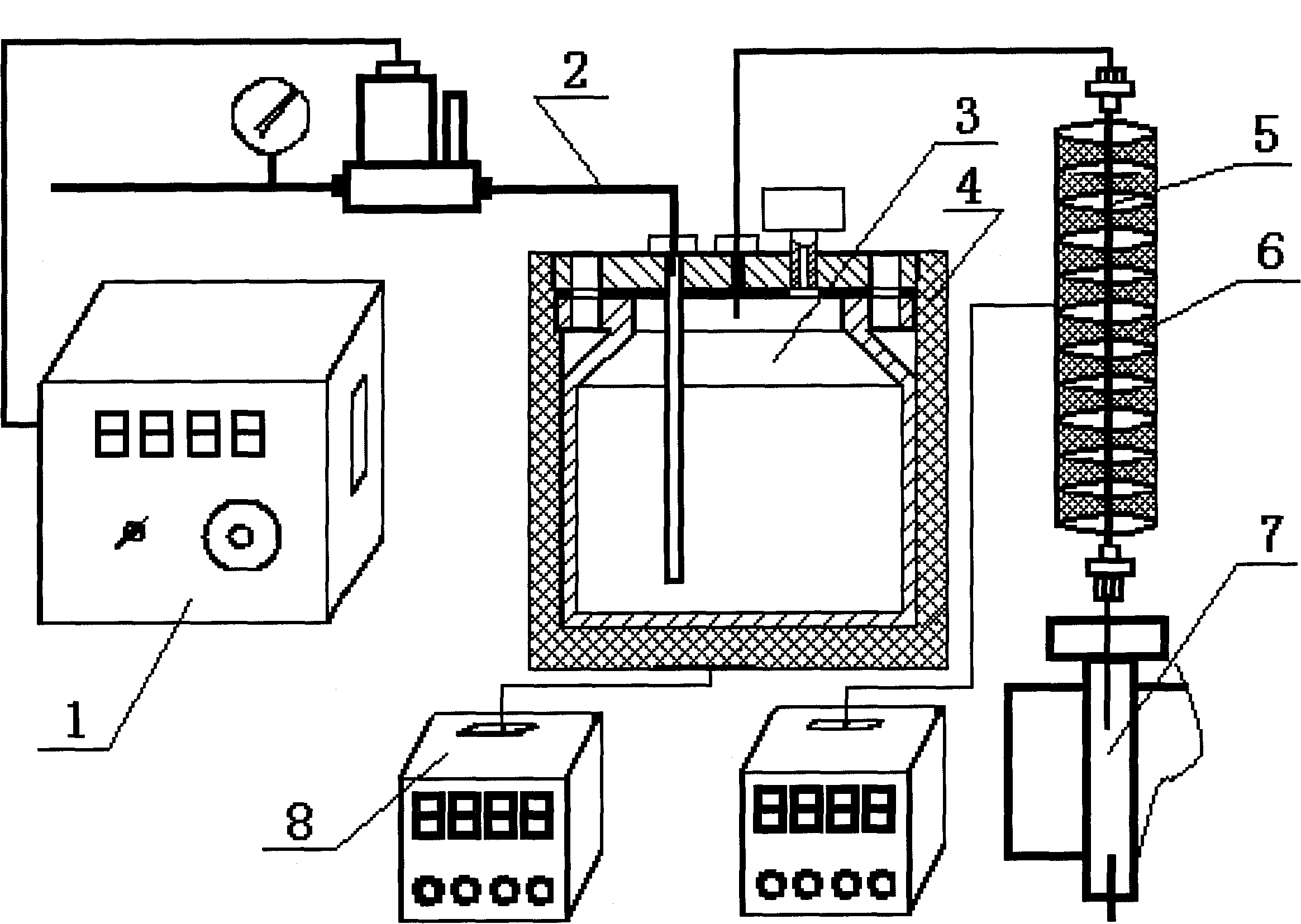

[0021] refer to figure 1 . Source rock airtight ball milling, heating analysis, cold trap trap chromatography online analysis device, mainly composed of sealed ball milling tank 3, ball milling tank heating insulation body 4, transmission pipeline 5, pipeline heating insulation body 6, chromatograph 7 and temperature control device 8 composition. The sealed ball milling tank 3 mainly includes a tank body and an upper cover. The tank body is cylindrical, with an inner diameter of 110 mm, a height of 106 mm, and a diameter of 80 mm. The upper cover has an air outlet, an air inlet and a pressure gauge port. Install a pressure gauge on the pressure gauge port. The sealed ball mill jar 3 upper cover is fixed on the jar mouth and is sealed by a gasket.

[0022] The air inlet of the sealed ball milling tank 3 is airtightly connected with a helium gas pipeline 2, the helium gas pipeline 2 is connected with a mass flow meter 1, and outside (around) the sealed ball milling tank 3, t...

Embodiment 2

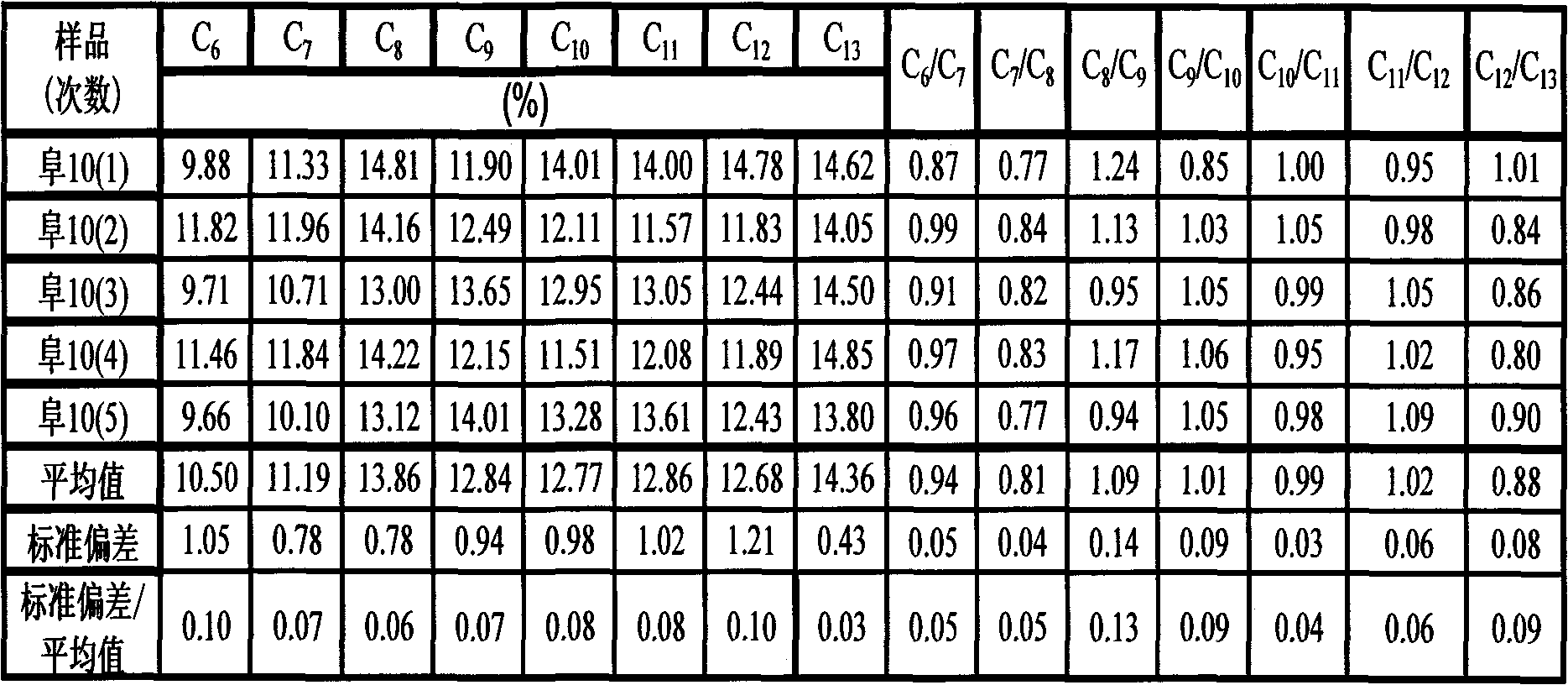

[0034] Taking a light crude oil from Well Pinghu 4 as an example, the light fraction compounds were analyzed by means of source rock closed ball milling, heating analysis, and cold trap trap chromatography on-line analysis methods. The purpose of this experiment is to test the reliability and repeatability of this device . Operation method is the same as embodiment 1, difference:

[0035] The light crude oil sample from Pinghu No. 4 Well was directly injected into the vacuumized sealed ball mill tank 3, and the rest of the operations were the same as in Example 1. The results of five consecutive repeated tests are shown in Table 2.

[0036] Table 2 Repeatability experiment results of five consecutive analyzes of light crude oil in Well Pinghu 4

[0037]

[0038] It can be seen from Table 2 that the same light oil was analyzed five times C 6 ~C 13 The peak area of each n-alkane relative to C 6 ~C 13 The standard deviations of the percentage content of the total area ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Caliber | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com