High-fluorine negative photoresist and application thereof to polymer optical waveguide device

A negative photoresist, polymer technology, applied in the direction of light guides, optical components, instruments, etc., can solve the problem of large light loss and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

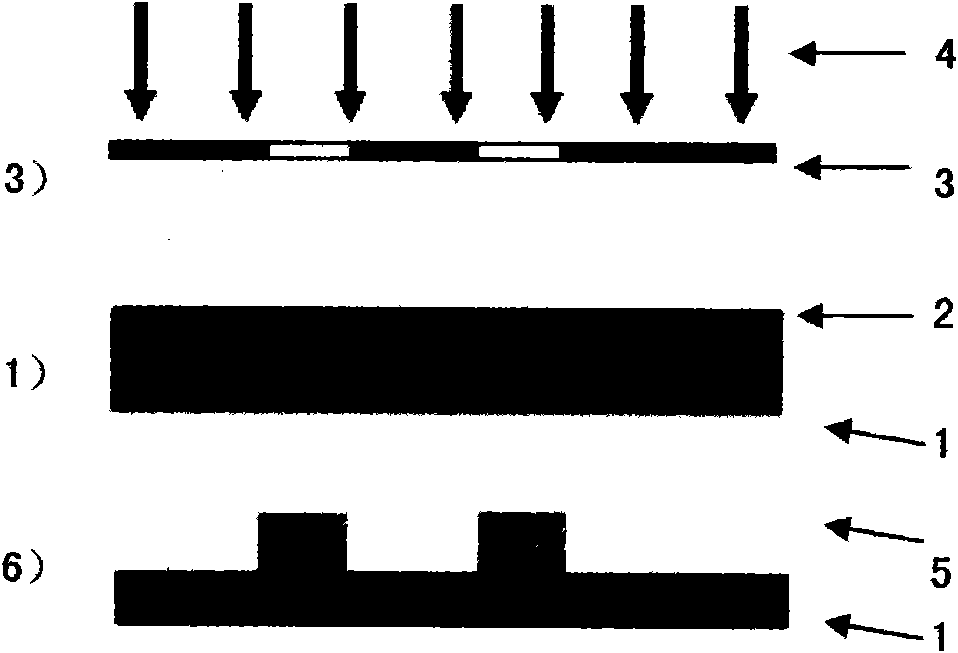

Method used

Image

Examples

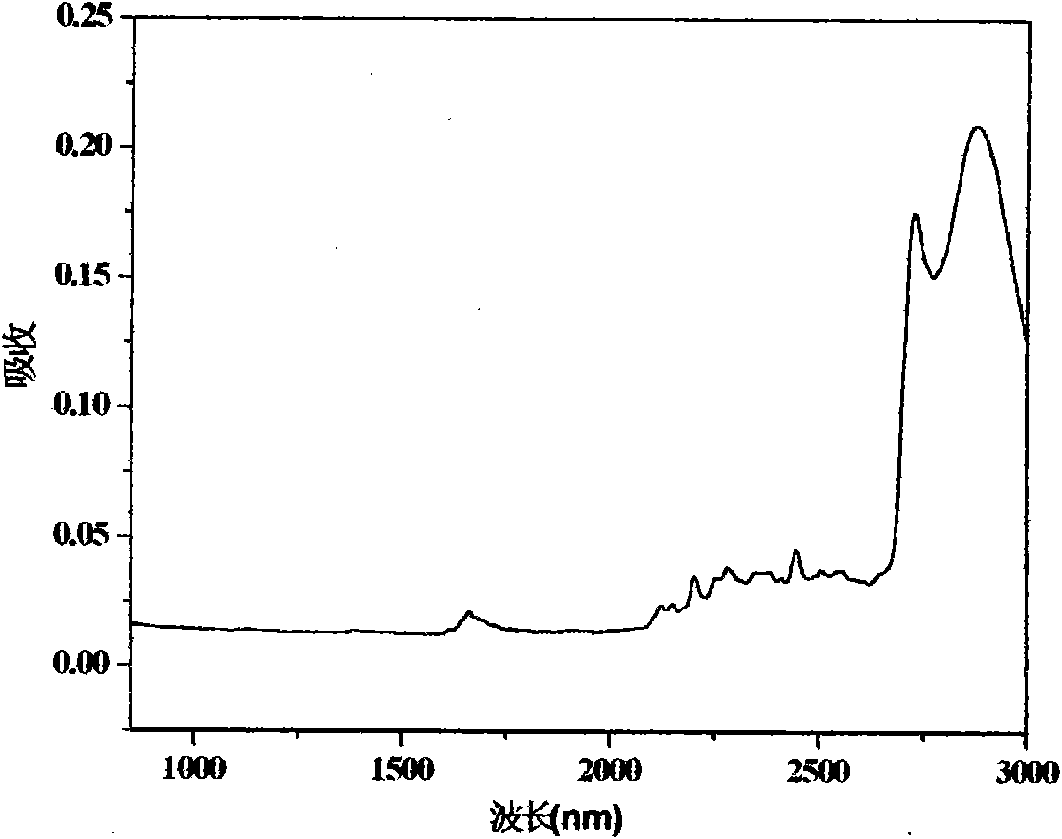

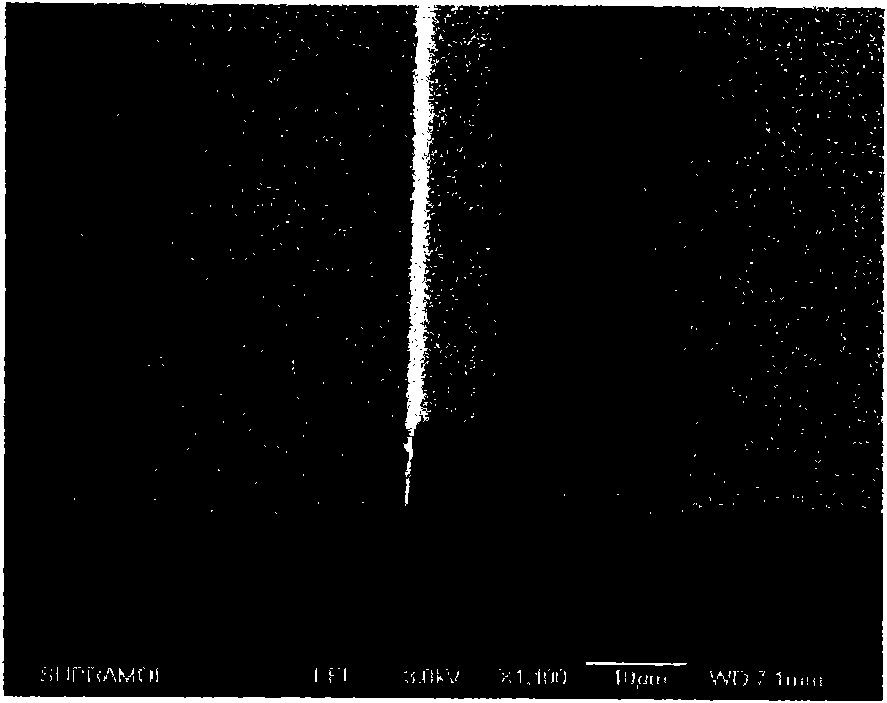

Embodiment 1

[0029] Dissolve 2.00g of pentafluorostyrene and 5.00g of fluorine-containing bisphenol A in 25ml of N,N-dimethylacetamide, and add the catalyst CaH 21.37g, CsF 0.13g, the mixture was heated up to 80°C, and reacted at this temperature for 18h. Filter to obtain a clear liquid. The solvent was evaporated. Column chromatography (ethyl acetate:petroleum ether=1:5) gave pure product. Dissolve the upper product in 25g of epichlorohydrin, catalyze it with solid caustic soda, add 0.04g of NaOH every 0.5h, and react for 8 hours in total. After the addition, keep at 60°C for 6h to complete the cyclization reaction. Steam unreacted epichlorohydrin, then extract with benzene, filter and evaporate benzene. The product from the previous step was dissolved in N,N-dimethylacetamide, 0.05 g of azobisisobutyronitrile was added, and the reaction was carried out at 60° C. for 6 h under nitrogen gas. The solvent is evaporated to obtain a high fluorine-containing epoxy resin with the following ...

Embodiment 2

[0033] Dissolve 2.00g of pentafluorostyrene and 3.40g of bisphenol A in 25ml of N,N-dimethylacetamide, add catalyst CaH 2 1.37g, CsF0.13g, the mixture was heated to 80°C and reacted at this temperature for 18h. Filter to obtain a clear liquid. The solvent was evaporated. Column chromatography (ethyl acetate:petroleum ether=1:4) gave pure product. Dissolve the upper product in 25g of epichlorohydrin, catalyze it with solid caustic soda, add 0.05g of NaOH every 0.5h, and react for a total of 8 hours. After the addition, keep at 60°C for 6h to complete the cyclization reaction. Steam unreacted epichlorohydrin, then extract with benzene, filter and evaporate benzene. The above product was dissolved in N,N-dimethylacetamide, 12 g of pentafluorostyrene was added, 0.10 g of initiator azobisisobutyronitrile was added, and the reaction was carried out at 60° C. for 6 h under nitrogen gas. The solvent is evaporated to obtain a high fluorine-containing epoxy resin with the followin...

Embodiment 3

[0037] Dissolve 2.00g of pentafluorostyrene and 5.00g of fluorine-containing bisphenol A in 25ml of N,N-dimethylacetamide, add the catalyst CaH 2 1.37g, CsF0.13g, the mixture was heated to 80°C and reacted at this temperature for 18h. Filter to obtain a clear liquid. The solvent was evaporated. Column chromatography (ethyl acetate:petroleum ether=1:5) gave pure product. Dissolve the upper product in 25g of epichlorohydrin, catalyze it with solid caustic soda, add 0.04g of NaOH every 0.5h, and react for 8 hours in total. After the addition, keep at 60°C for 6h to complete the cyclization reaction. Steam unreacted epichlorohydrin, then extract with benzene, filter and evaporate benzene. The above product was dissolved in N,N-dimethylacetamide, 15 g of pentafluorostyrene and 0.11 g of initiator azobisisobutyronitrile were added, and the reaction was carried out at 60° C. for 6 h under nitrogen gas. The solvent is evaporated to obtain a high fluorine-containing epoxy resin w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| dispersity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com