Method for forming composite rhBMP-2 elasticity modulus graded porous titanium alloy support rod for femoral head and neck

An elastic modulus, rhbmp-2 technology, applied in medical science, prosthesis and other directions, can solve the problems of not taking into account the changing characteristics of the femoral head and neck, affecting the repair and reconstruction of the support rod bone, and the complex preparation process of porous tantalum rods. Achieve stable osteoinductive performance, avoid stress shielding effect, and good osteoconductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0021] The preparation method of the present invention is as follows:

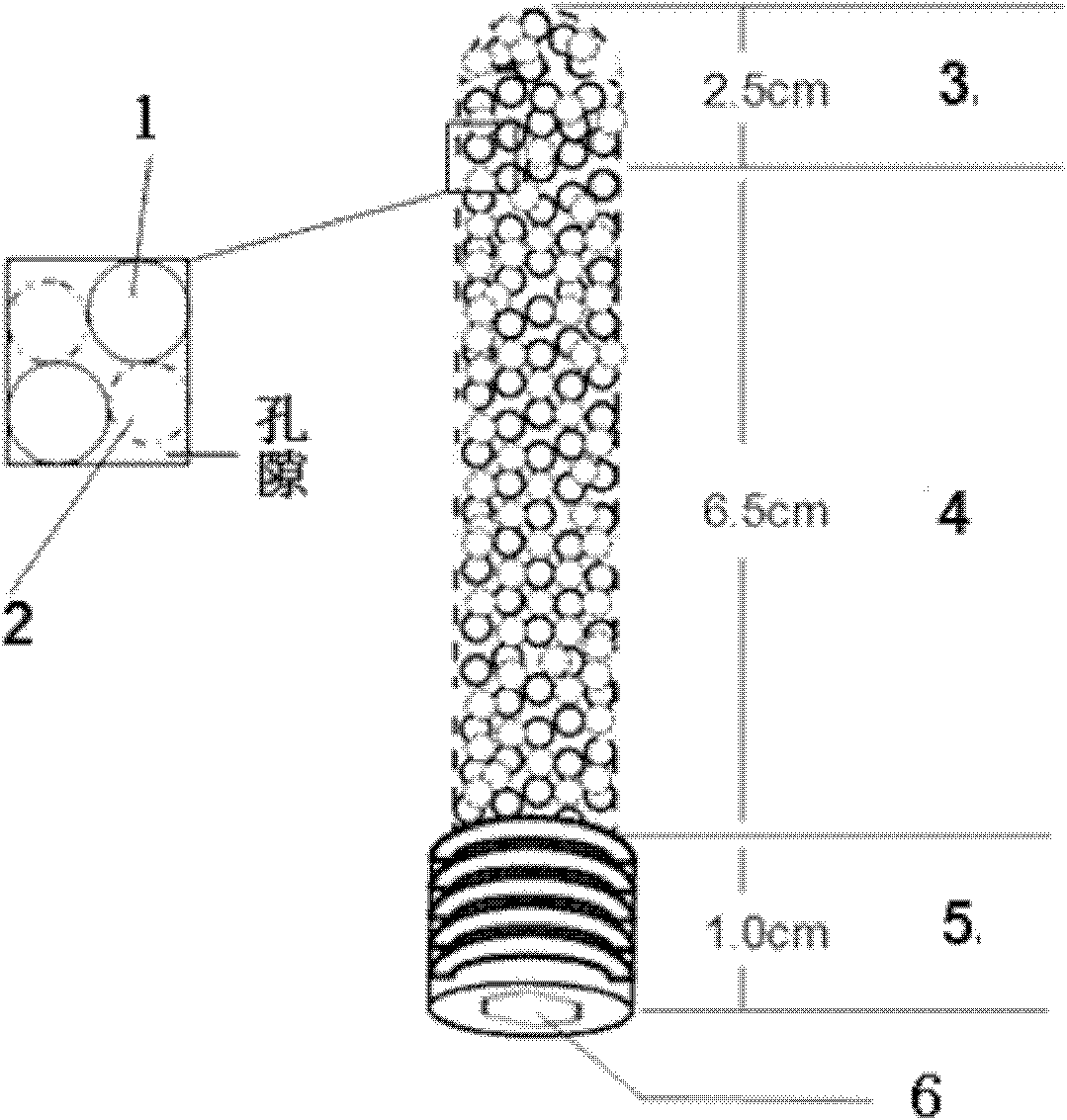

[0022] 1) Preparation of Porous Titanium Alloy Support Rods with Gradual Elastic Modulus

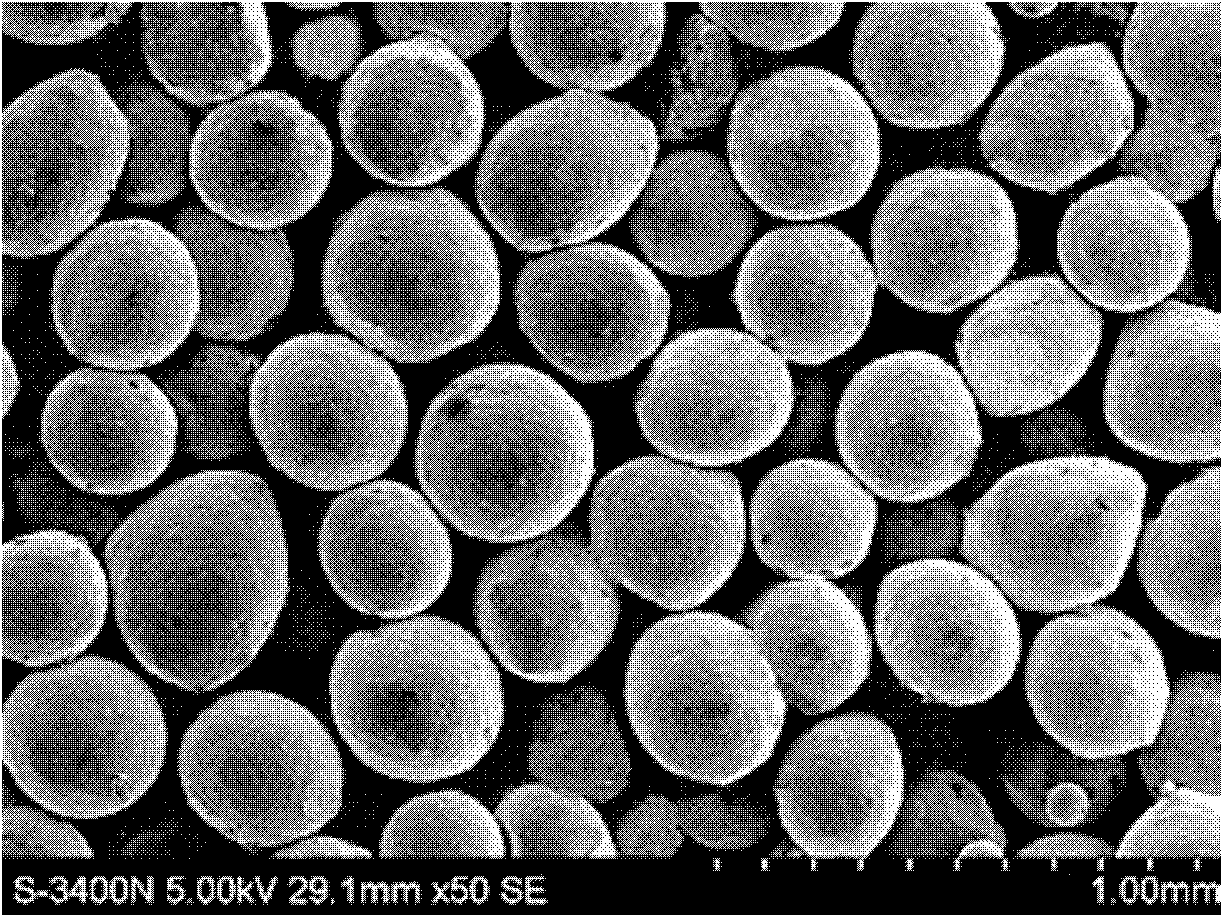

[0023] Firstly, the titanium alloy powder is prepared by the "electrode induction melting gas atomization method", and then the prepared titanium alloy powder and the pore-forming agent polymethyl methacrylate are mixed and processed to form a powder block by the "cold rolling method". The body is sintered at 1000-1400°C to obtain a porous titanium alloy bulk material. During the production process, according to the measured biomechanical parameters of the femoral head, neck, and rotor, by adjusting the volume ratio of titanium alloy powder to the pore-forming agent polymethyl methacrylate, and the particle size of the pore-forming agent, the Change the porosity and pore size of the material in or...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com