Method for utilizing pyrolysis C9 by performing catalytic reforming

A technology of catalytic upgrading and catalytic devices, which is applied in cracking, catalytic cracking, petroleum industry, etc., and can solve the problems of cracking C9 resource waste and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

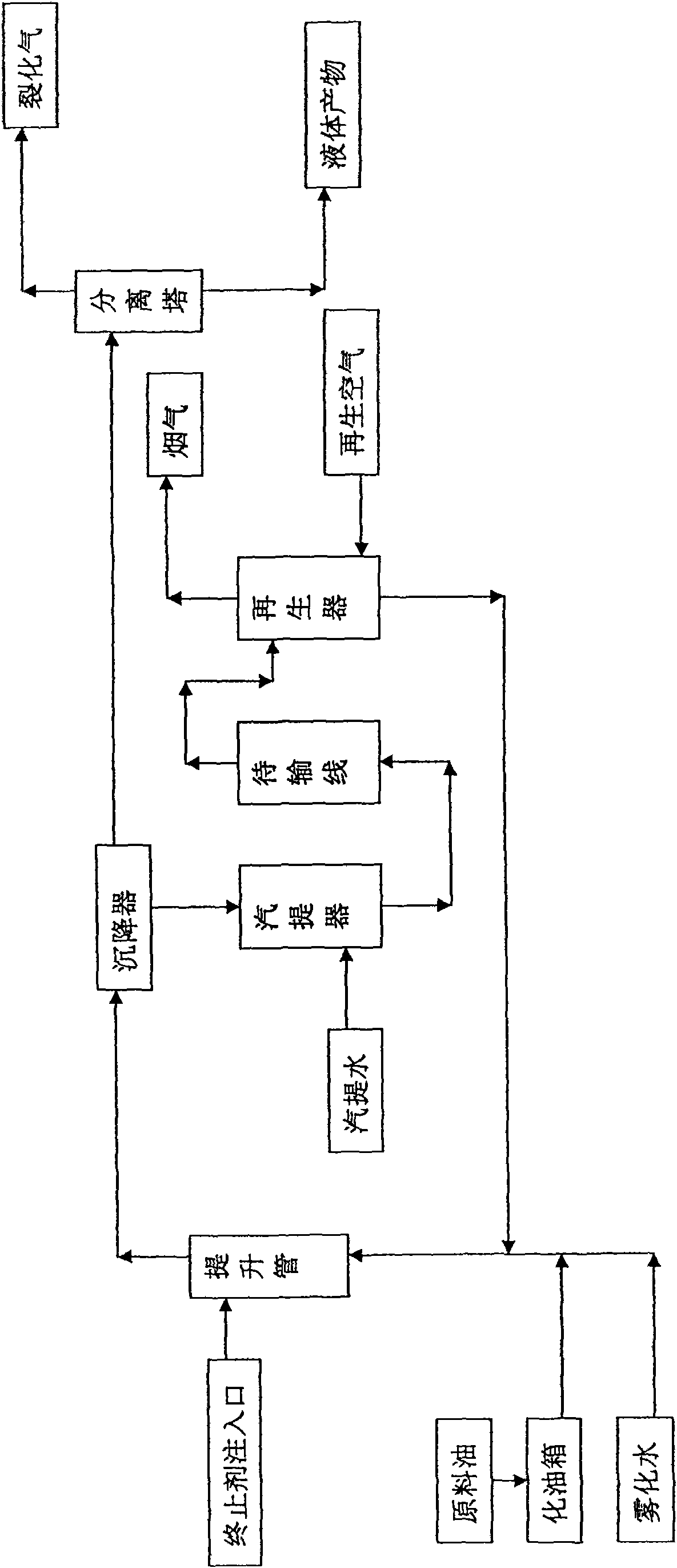

Method used

Image

Examples

Embodiment 1

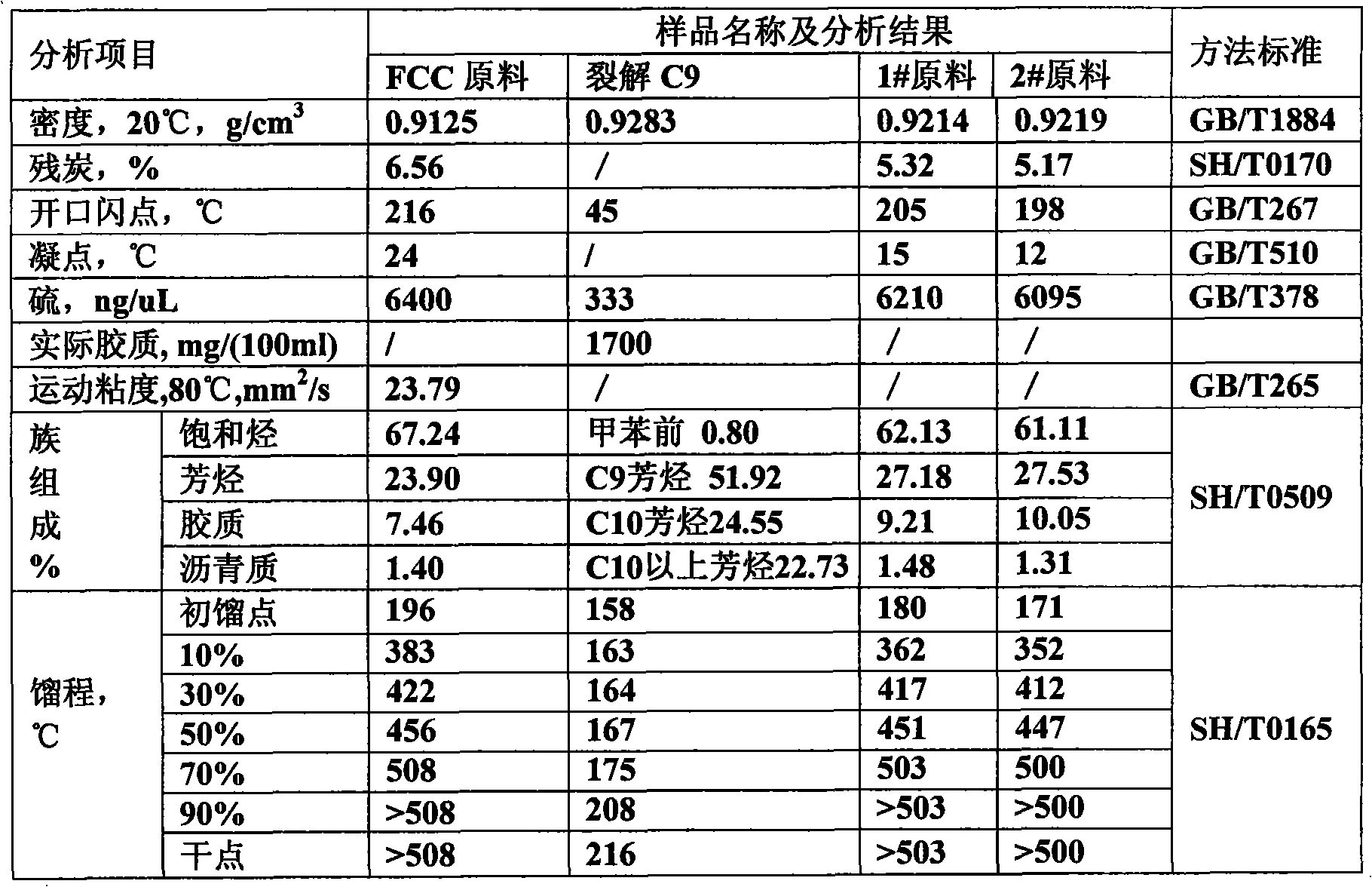

[0012] Mix the cracked C9 with the FCC raw material of an oil refinery. The mixing ratio is 1# mixed raw material 95% FCC raw material + 5% cracked C9, 2# mixed raw material is 90% FCC raw material + 10% cracked C9, cracked C9, FCC raw material and The properties of the mixed raw materials are shown in Table 1.

[0013] Table 1 Raw material properties

[0014]

Embodiment 2

[0016] 1# raw material, 2# raw material and FCC raw material were used to carry out the catalytic cracking evaluation test on the riser device, and the catalyst used in the test was the catalyst used in the catalytic device of a certain oil refinery. The process conditions are: reaction temperature 505°C, regeneration temperature 700°C, agent-oil ratio 5.0. In the evaluation tests, oil was fed continuously for 10 hours, and the amount of oil fed was 8kg. The resulting oil was subjected to true boiling point distillation and cut to obtain gasoline, diesel oil and heavy oil. The product distribution obtained in the evaluation test is shown in Table 2.

[0017] Table 2 Evaluation Test Gained Product Distribution % (m)

[0018] Raw oil

[0019] light oil yield,

Embodiment 3

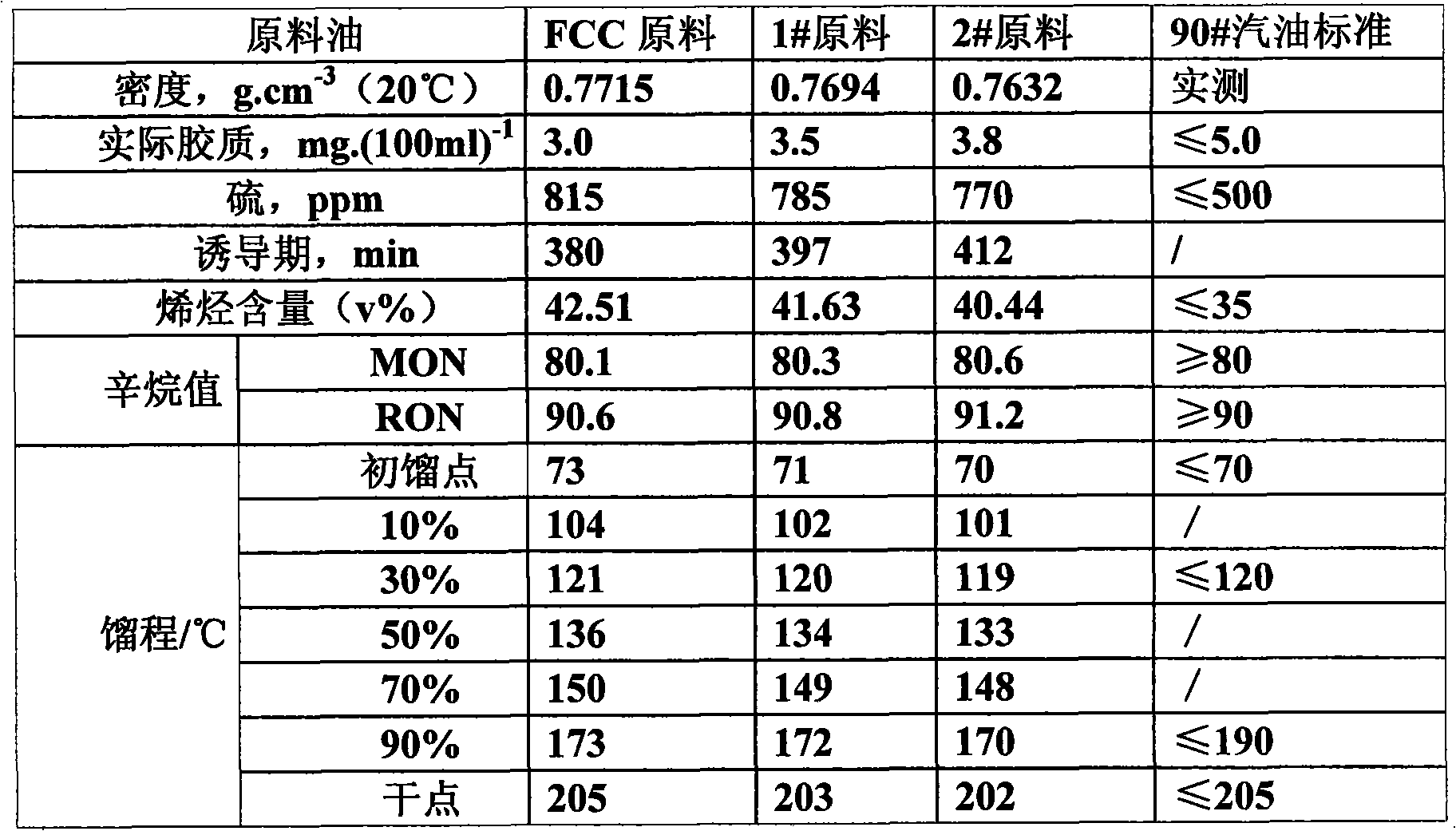

[0021] The generated oil obtained in the evaluation test of Example 2 is accumulated as an oil sample, and the generated oil is distilled and cut on a real boiling point distillation device to obtain catalytic gasoline and catalytic diesel oil (wherein the catalytic gasoline fraction is the initial boiling point ~ 200 ° C, and the catalytic diesel fraction is 200 ° C ~350°C), the properties of the cut catalytic gasoline were analyzed, and the analysis results are shown in Table 3.

[0022] Table 3 evaluates the properties of test-gained catalytic gasoline

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com