Porous foam metal based embedded type solid self-lubricating composite material and preparation method thereof

A technology of porous metal foam and solid lubricating material, applied in the field of materials, can solve the problems of limiting the longitudinal thickness of plastics and reducing the wear resistance life, and achieves improved thermal conductivity, good thermal conductivity, improved expansion force and inherent cold flow. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

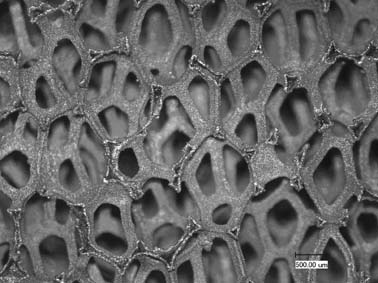

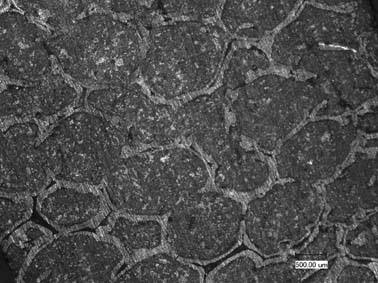

[0012] Metal foam: a copper foam, characteristic parameters: average pore diameter 0.96mm, PPI (pores per inch) 28, porosity 93%, density 0.62 g / cm 3 , Compressive strength 1.76MPa.

[0013] The weight percentage of each component of the solid lubricant: polytetrafluoroethylene 80%, graphite 20%.

[0014] The manufacturing process of the composite material is as follows: firstly, the mixed components of the solid lubricant are dispersed in volatile anhydrous ethanol to form a suspension by ultrasonication, and then the solid lubricant is dripped and filled into the foam with the aid of a vacuum pump with the help of a vacuum pump. The inside of the metal, then air-dried for 2 hours to remove the organic solvent, cold-pressed at 60MPa for 5 minutes to maintain the compactness of the entire system, and finally sintered in a sintering furnace for 120 hours between 330°C and 370°C min, cooling and forming.

[0015] The above-prepared copper foam-based composite with a density of...

Embodiment 2

[0020] The weight percentage of each component of the solid lubricant: polytetrafluoroethylene 70%, graphite 30%. The metal foam used and the method of making and testing are the same as in Example 1.

[0021] The copper foam-based composite material prepared in this example has a density of 3.21 g / cm 3 , Shore hardness 64 degrees, thermal diffusivity at 25°C 2.01mm 2 / s, resistivity 5.8×10 -5 Ωm. Some of its tribological properties are shown in Table 2; at the end of the friction stage, a digital thermometer was used to measure the friction temperature of the composite material on the approaching friction surface. The homogeneous polymer was 148°C.

[0022] Table 2. Comparison of tribological properties of different types of composite materials (500N, V=0.856m / s)

[0023] sample

Embodiment 3

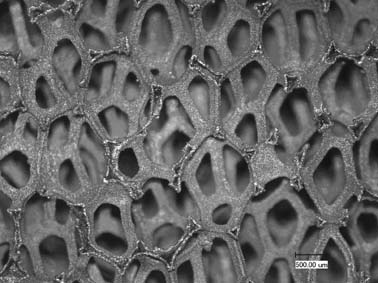

[0025] Metal foam: a copper foam, characteristic parameters: average pore diameter 1.50mm, PPI (pores per inch) 18, porosity 96%, density 0.35 g / cm 3 , Compressive strength 0.52MPa.

[0026] The solid lubricant chooses pure polytetrafluoroethylene (PTFE) as a single filler. Concrete production and test method are the same as embodiment 1.

[0027] The composite material based on foamed copper prepared in this example has a density of 2.46 g / cm 3 , Shore hardness 61 degrees, thermal diffusivity at 25°C 1.00mm 2 / s, resistivity 1.5×10 -4 Ωm. Some of its tribological properties are shown in Table 3, and the pure PTFE sample will fail after 30 minutes of grinding.

[0028] Table 3. Comparison of tribological properties of different types of composite materials (500N, V=0.424m / s)

[0029] sample

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com