Method for solidifying and dry-stacking mill tailings without tailing reservoir

A solidification treatment and tailings pond technology, which is applied in the field of mines and environmental engineering, can solve the problems of large tailings pond stability or environmental safety risks, and achieve the effects of saving area, low processing cost and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

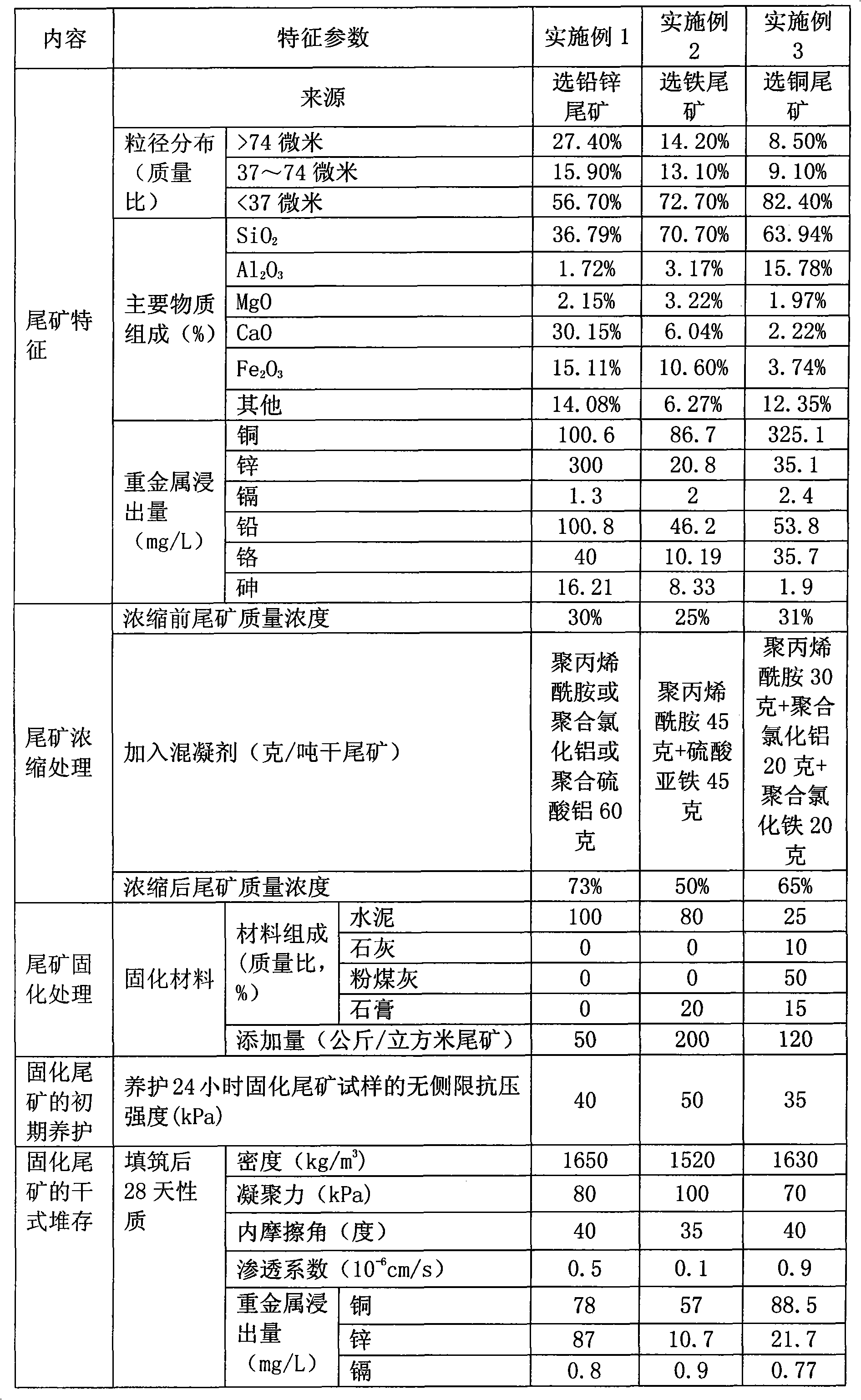

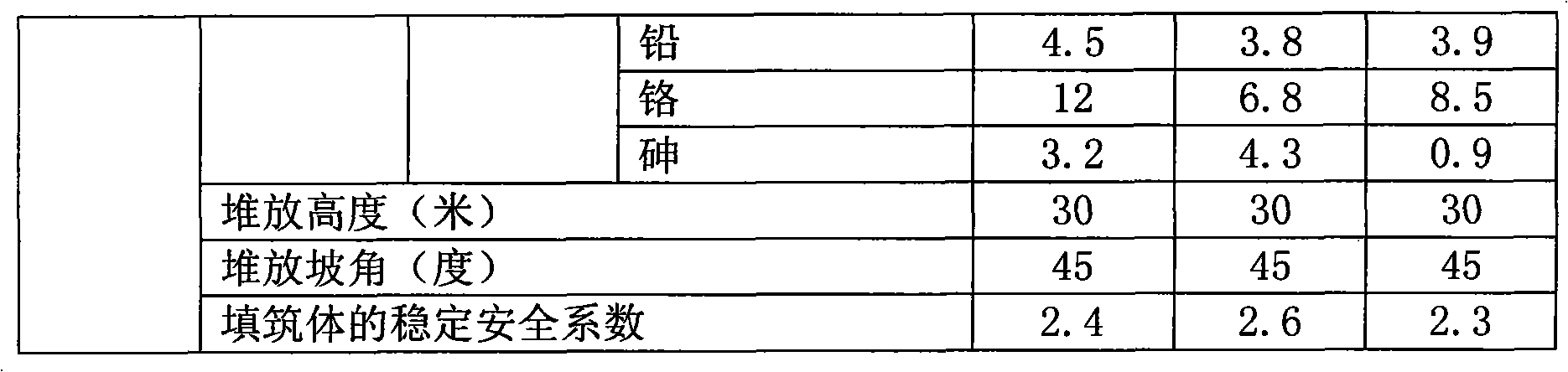

Embodiment 1

[0027] A lead-zinc tailings, in which the particle content of >74 microns accounts for 27.40%, the content of particles of 37-74 microns accounts for 15.90%, and the content of particles 2 Accounted for 36.79%, Al 2 o 3 1.72%, MgO 2.15%, CaO 30.15%, Fe 2 o 3Accounted for 15.11%, other ingredients accounted for 14.08%. The tailings were tested according to HJ / T299-2007 method, the leaching amount of copper in untreated tailings was 100.6mg / L, zinc was 300mg / L, cadmium was 1.3mg / L, lead was 100.8mg / L, chromium was 40mg / L, arsenic 16.21mg / L. The mass concentration of the tailings before concentration is 30%, and 60 grams of polyacrylamide or polyaluminum chloride or polyaluminum sulfate is added per ton of dry tailings, and the tailings with a mass concentration of 73% are formed after precipitation for 6 hours. Add 80 kg of cement curing agent to each tailings for mixing and stirring. After stirring, the unconfined compressive strength of the solidified tailings sample after...

Embodiment 2

[0029] A kind of iron tailings, wherein the particle content of >74 microns accounts for 14.20%, the content of particles of 37-74 microns accounts for 13.10%, and the content of particles of 2 70.70%, Al 2 o 3 3.17%, MgO 3.22%, CaO 6.04%, Fe 2 o 3 Accounted for 10.60%, other ingredients accounted for 6.27%. The tailings were tested according to HJ / T299-2007 method, the leaching amount of copper in untreated tailings was 86.7mg / L, zinc was 20.8mg / L, cadmium was 2mg / L, lead was 46.2mg / L, chromium was 10.19mg / L, arsenic 8.33mg / L. The mass concentration of the tailings before concentration is 25%. Add 45 grams of polyacrylamide and 45 grams of ferrous sulfate per ton of dry tailings, and settle for 6 hours to form tailings with a mass concentration of 50%. Add 200 kilograms of curing agent (wherein cement accounts for 80% and gypsum accounts for 20%) in each cubic tailings to mix and stir. After stirring, the unconfined compressive strength of the solidified tailings sample f...

Embodiment 3

[0031] A copper beneficiation tailings, in which the particle content of >74 microns accounts for 8.50%, the content of particles of 37-74 microns accounts for 9.10%, and the content of particles 2 Accounted for 63.94%, Al 2 o 3 Accounted for 15.78%, MgO accounted for v%, CaO accounted for 2.22%, Fe 2 o 3 Accounted for 3.74%, other ingredients accounted for 12.35%. The tailings were tested according to the HJ / T299-2007 method. The leached amount of copper in untreated tailings was 325.1mg / L, zinc was 35.1mg / L, cadmium was 2.4mg / L, lead was 53.8mg / L, chromium 35.7mg / L and 1.9mg / L arsenic. The mass concentration of tailings before concentration is 31%. Add 30 grams of polyacrylamide, 20 grams of polyferric chloride and 20 grams of polyferric chloride per ton of dry tailings, and settle for 6 hours to form tailings with a mass concentration of 65%. Add 120 kilograms of solidifying agent (wherein cement accounts for 25%, lime accounts for 10%, fly ash accounts for 50%, gypsum ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cohesion | aaaaa | aaaaa |

| Angle of internal friction | aaaaa | aaaaa |

| Permeability coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com