Method for making support body of porous ceramic filter pipe capable of improving strength and pore connectivity

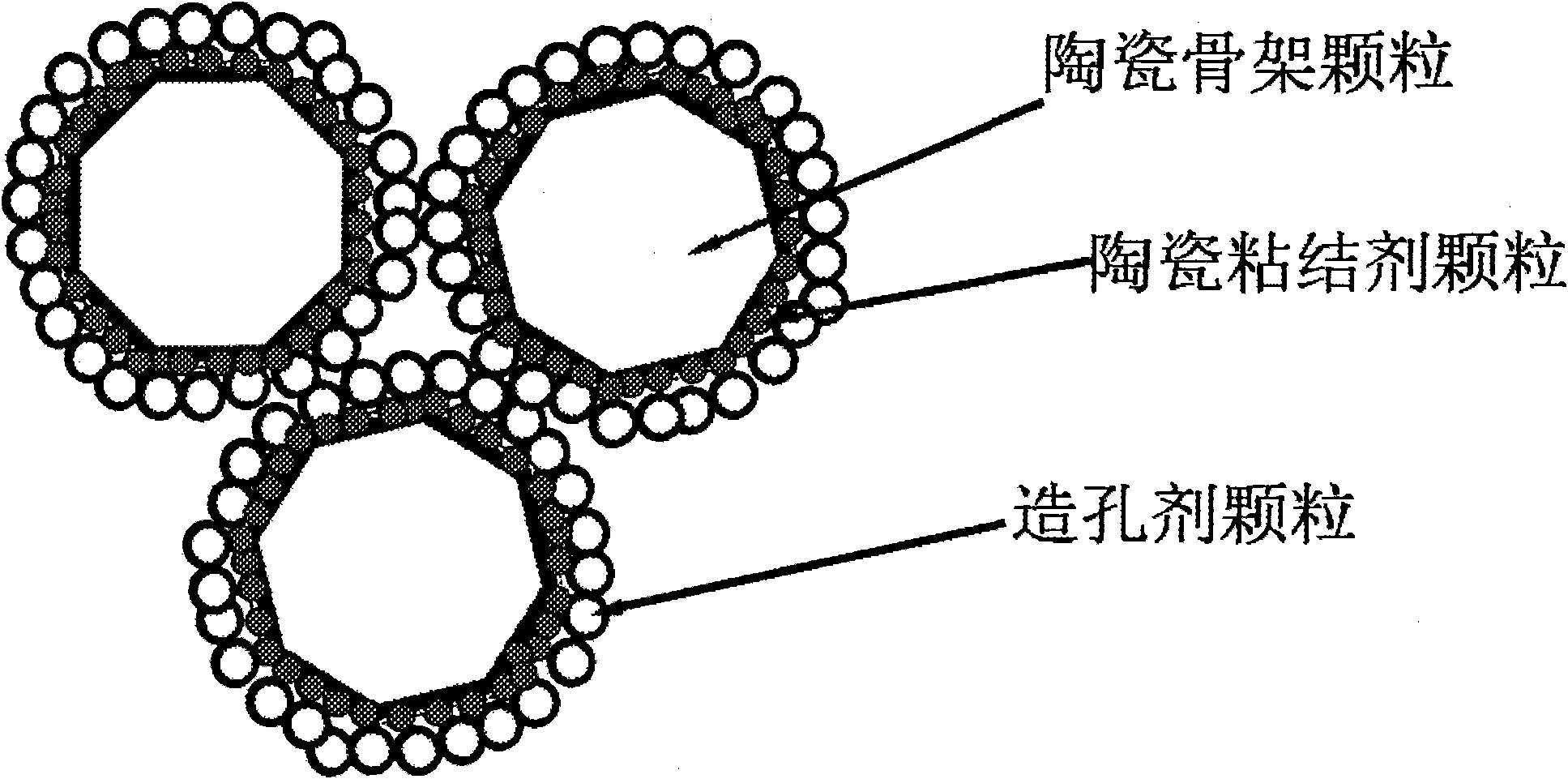

A technology for porous ceramics and strength improvement, applied in the field of ceramic materials, can solve the problems of reduced filtration rate, uneven distribution, easy agglomeration, etc., and achieve the effects of easy adjustment of porosity, high pore connectivity, and reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

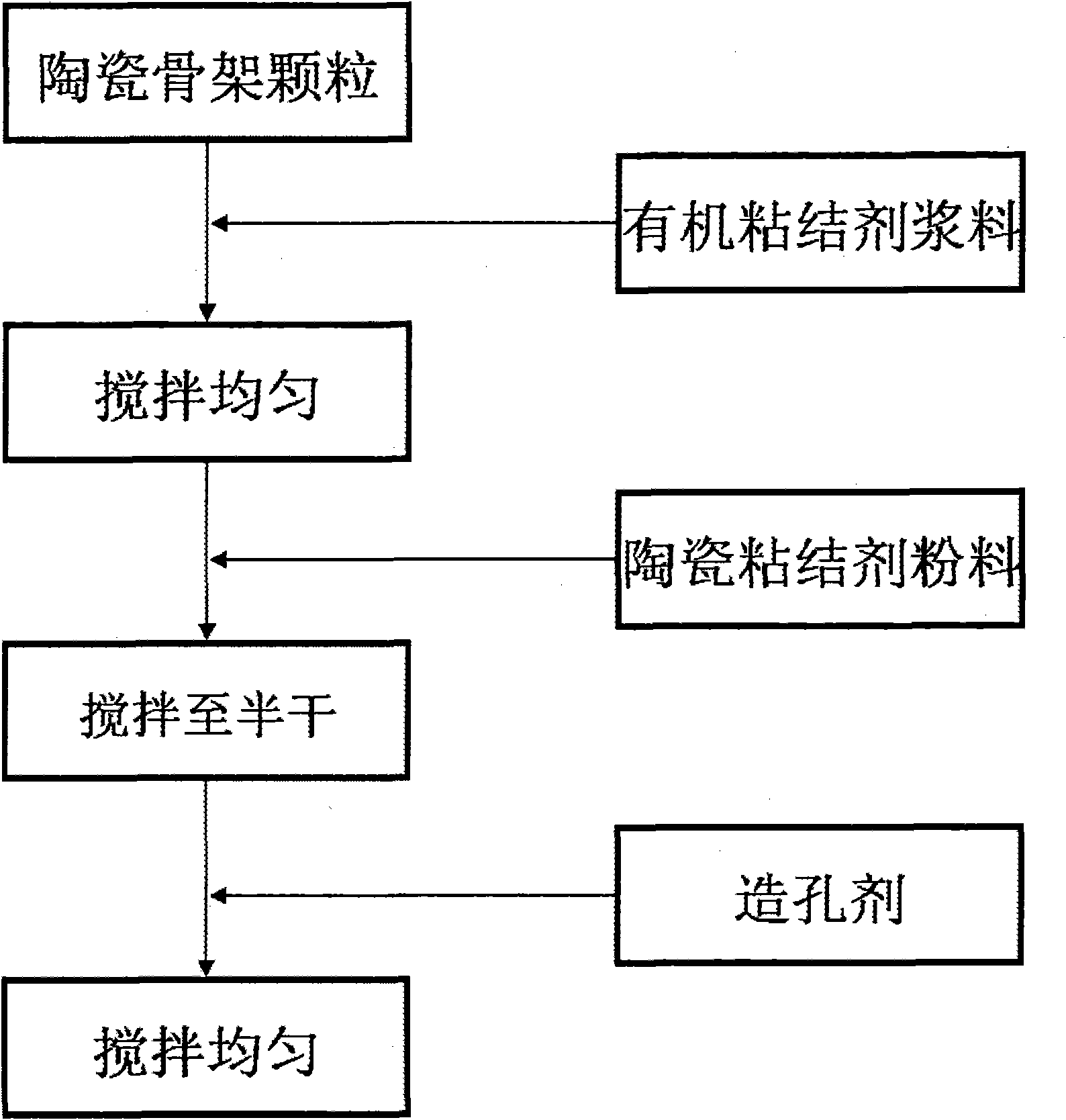

Method used

Image

Examples

preparation example Construction

[0042] Preparation of ceramic binder powder:

[0043] The mass fraction of 65% feldspar, 12% clay and 23% silicon oxide was ball milled and mixed with deionized water for 36 hours, and then dried at 100°C to obtain a mixed ceramic binder powder. The average particle size of the ceramic binder powder is 10 μm.

Embodiment 1

[0045] Firstly, an aqueous slurry of sodium carboxymethylcellulose with a mass fraction of 2% and an aqueous slurry of polyvinyl alcohol with a mass fraction of 5% were prepared. Add 2g sodium carboxymethylcellulose powder and 5g polyvinyl alcohol powder into two containers respectively, inject an appropriate amount of water, boil it under magnetic stirring, and dissolve sodium carboxymethylcellulose and polyvinyl alcohol and A uniform slurry was formed, and finally the total weight of the slurry was respectively 100 g.

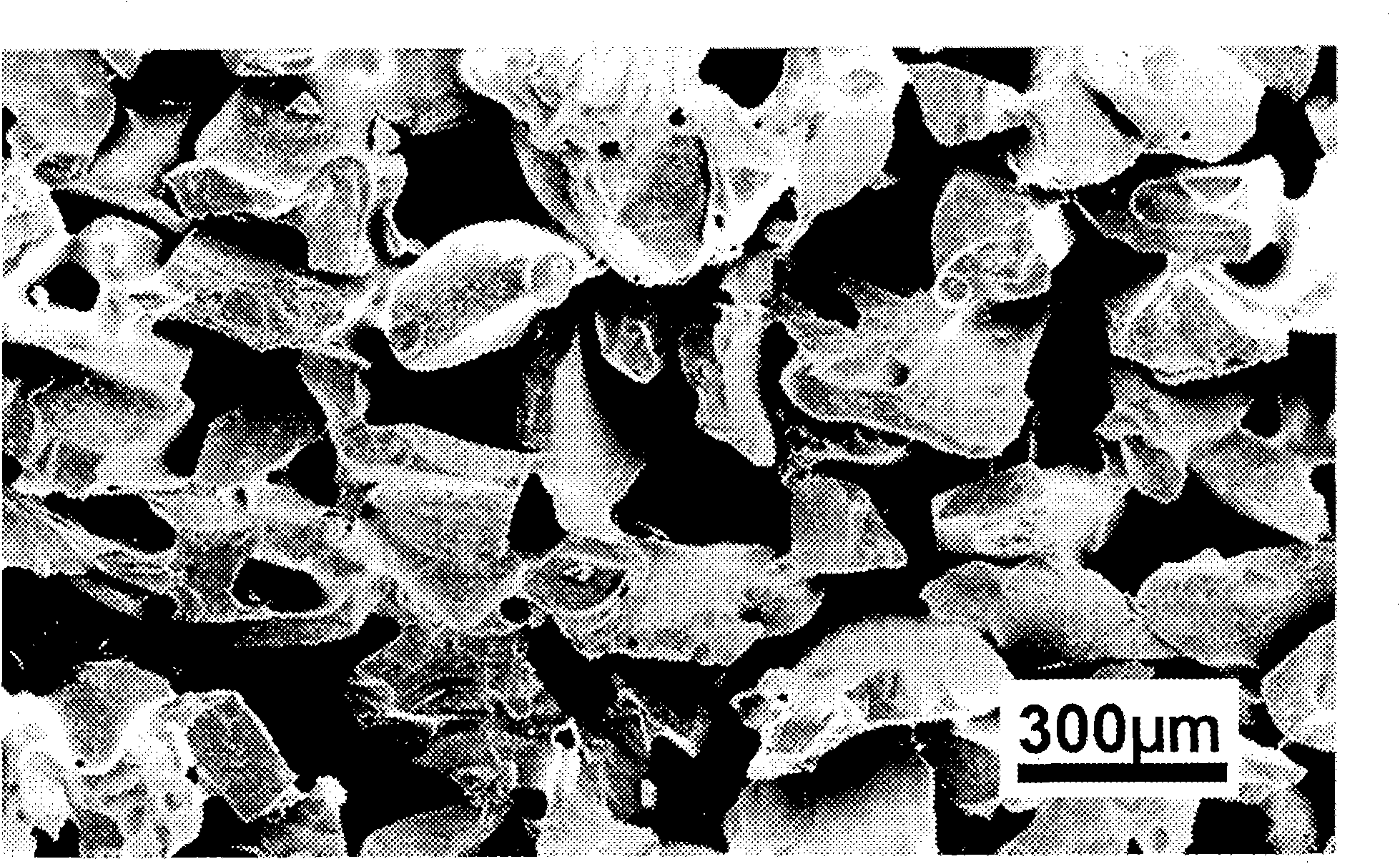

[0046] Fully mix 90 g of silicon carbide ceramic aggregate with a particle size of 300 μm and 10 g of sodium carboxymethyl cellulose slurry with a mass fraction of 2%, and then add 10 g of ceramic binder powder several times under constant stirring, and mix thoroughly. After mixing well, add 6g of graphite powder with an average particle size of 10μm, and mix thoroughly. Then, after dry pressing at 90MPa, it was sintered at 1300°C for 3h.

[0047] The test re...

Embodiment 2

[0049] Fully mix 85g of silicon carbide ceramic aggregate with a particle size of 300 μm and 7g of the sodium carboxymethylcellulose slurry with a mass fraction of 2% prepared in Example 1, and then add the ceramic binder in small amounts and several times while stirring continuously 15g of powder, mix thoroughly, then add 6g of graphite powder with an average particle size of 10μm, and mix thoroughly. Then, after dry pressing at 13MPa, it was sintered at 1300°C for 3h.

[0050] The test results are: using 300μm silicon carbide aggregate, adding 15% by mass fraction of ceramic binder, plus 6% by mass fraction of graphite powder pore-forming agent, after dry pressing at 13MPa and sintering at 1300°C for 3 hours, the obtained The porosity of the support is 39%, and the bending strength is 25MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com