Method for recovering metronidazole finished product from industrial waste residue of metronidazole

A technology of industrial waste residue and metronidazole, which is applied in the direction of organic chemistry and the like, and achieves the effects of simple and easy technological operation, low cost and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

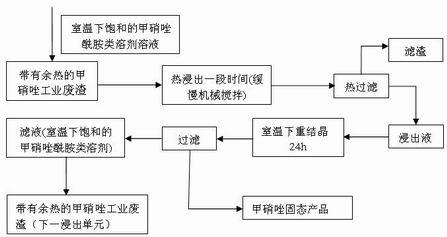

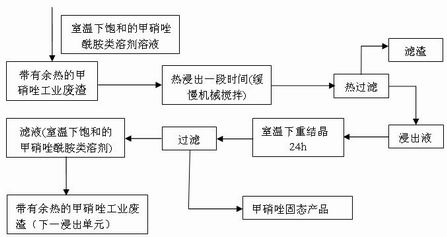

Method used

Image

Examples

Embodiment 1

[0023] To 100g of metronidazole industrial waste at 40°C, add 30mL of saturated metronidazole in N,N-dimethylformamide solution at room temperature, hot-dissolution leaching reaction for 10min, leachate (filtered filtrate) in Recrystallized at room temperature to obtain 1.40 g of metronidazole product at room temperature of 18°C.

[0024] Recovery rate and product purity measurement: adopt Hitachi L-7000 type high performance liquid chromatograph to detect the content of metronidazole in the metronidazole industrial waste residue and the product that finally obtains, to calculate the recovery rate of the present invention method and the purity of gained product . First, the analyte is treated with analytically pure N,N-dimethylformamide to form a solution, and then diluted to an appropriate metronidazole concentration (0.1g / L-3.0g / L) for sample detection.

[0025] The detection conditions of high performance liquid chromatography are: the mobile phase is methanol (chromatogra...

Embodiment 2-15

[0029] The quality of the industrial waste residue of metronidazole to be recovered in Examples 2-15 is 100g, and the extract solution added is 30mL of N,N-dimethylformamide solution of saturated metronidazole at room temperature. Other conditions and results are listed in in Table 2.

[0030]

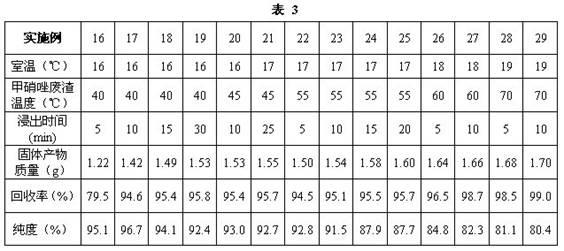

Embodiment 16-29

[0032] The mass of industrial waste residue of metronidazole to be recovered in Examples 16-29 is 100g, and the extract solution added is 35mL saturated metronidazole N,N-dimethylformamide solution at room temperature. Other conditions and results are listed in in Table 3.

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com