Preparation method of polyoxometallate-polymer hybridized segmented copolymer nanotube

A polyoxometalate and block copolymer technology is applied in the field of preparation of polyoxometalate-polymer hybrid block copolymer nanotubes, which can solve the problems of degradation, acidity sensitivity and the like, and achieve reproducibility. The effect of good performance, low cost and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

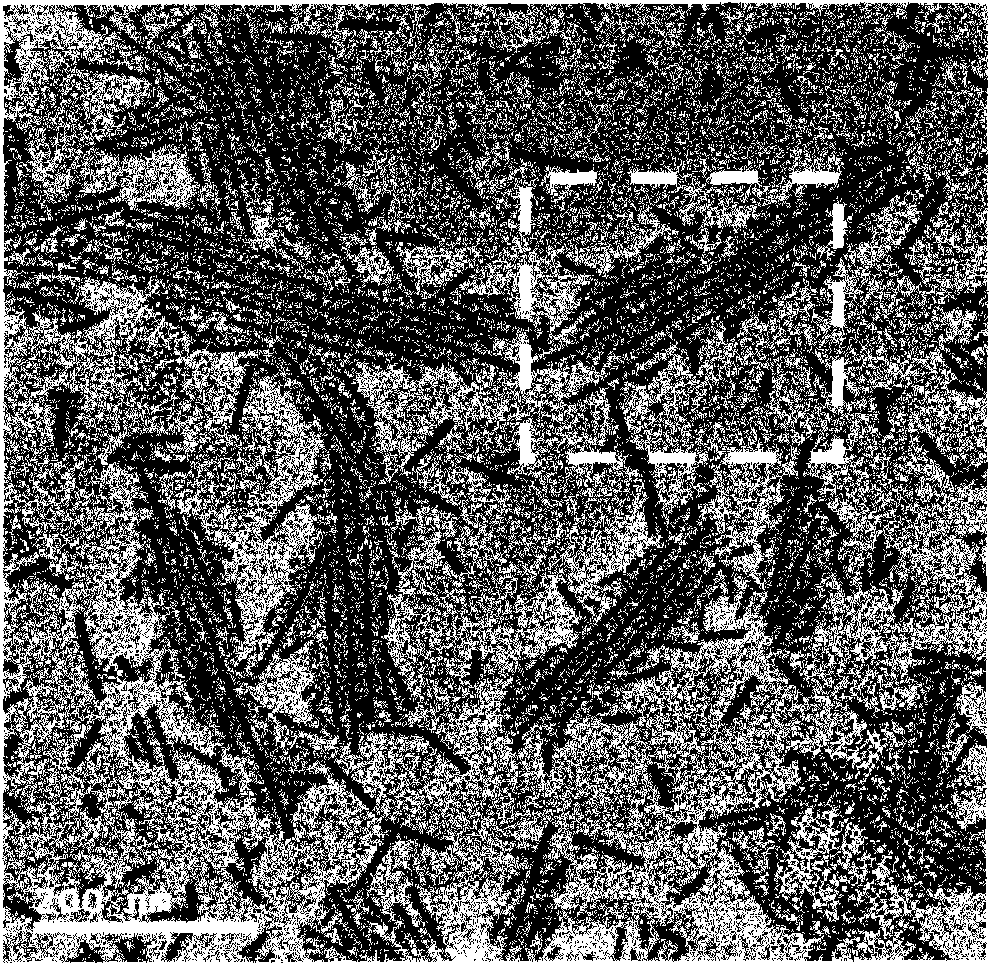

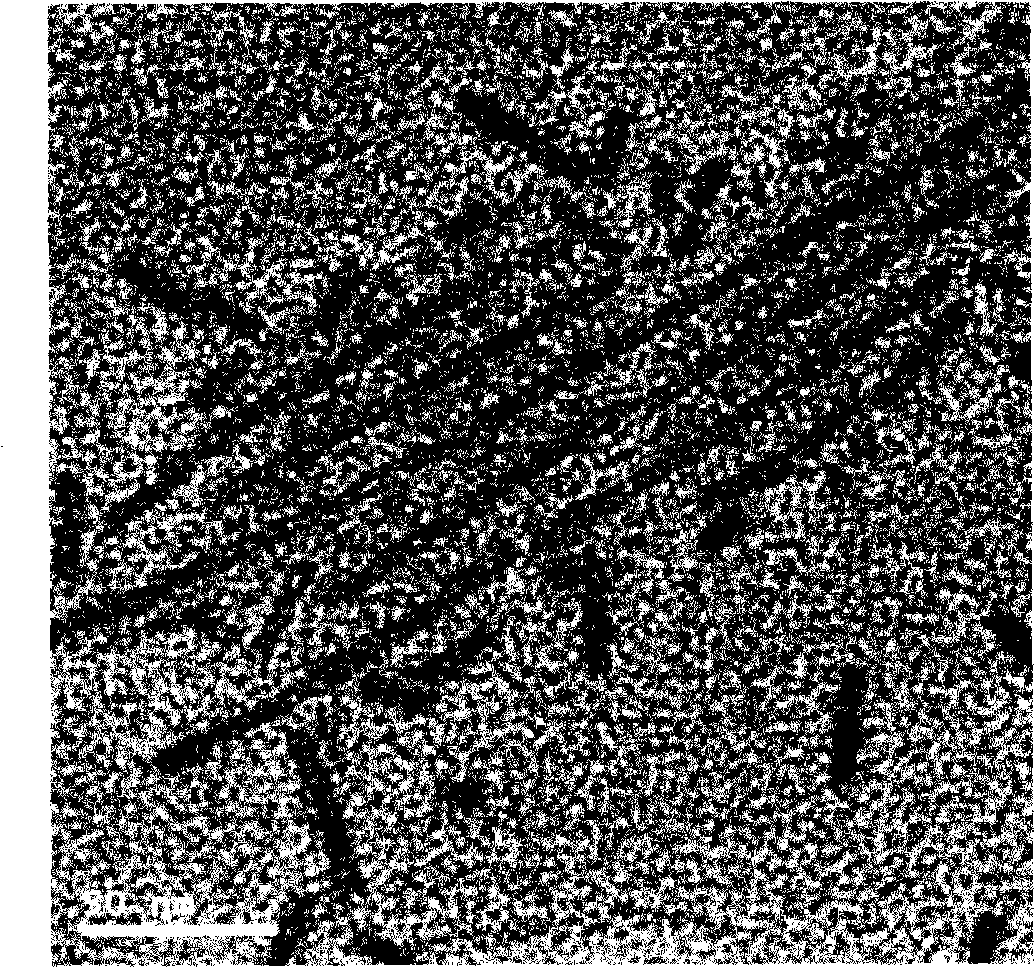

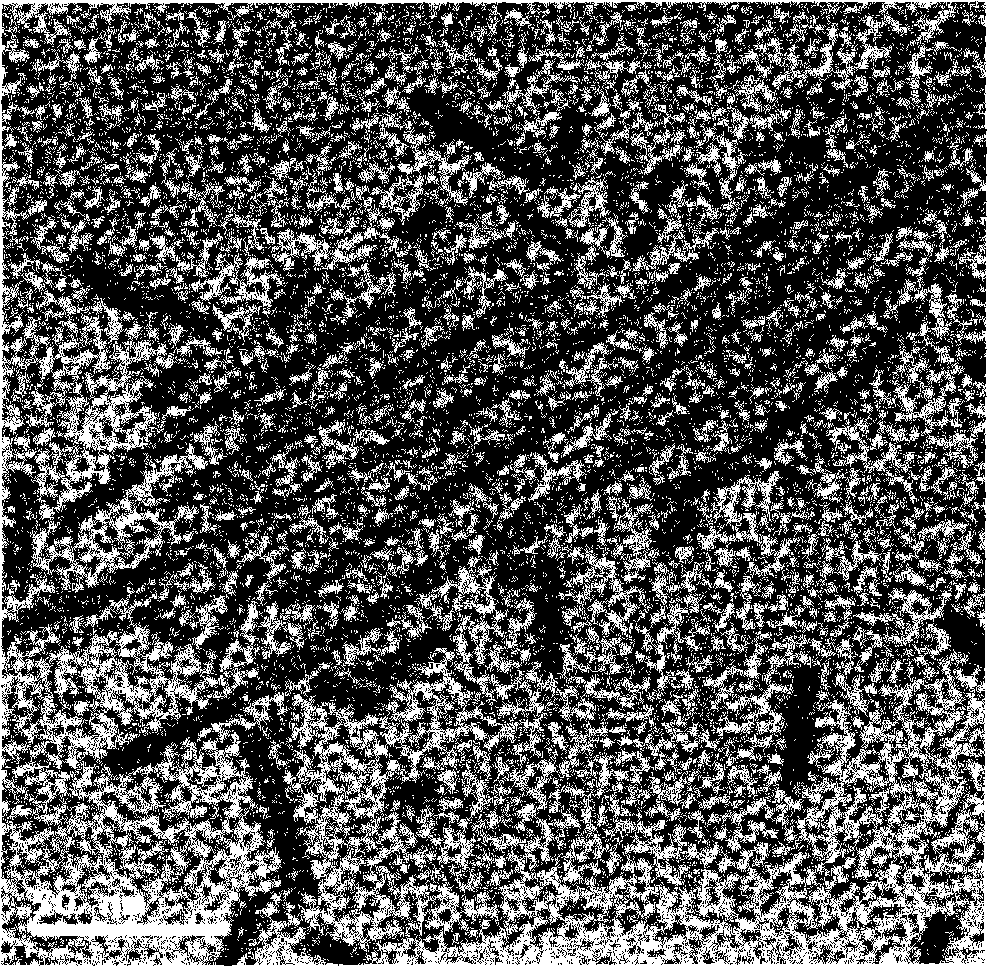

[0021] 1) Preparation of precursor solution

[0022] Using the aforementioned patented technology to prepare molecular weight It is a polyoxometalate-polymer hybrid block copolymer of 119,000g / mol, wherein the polyoxometalate is an organic ammonium salt of a Dawson structure phosphotungstovanadium polyoxometalate [(n-C 4 h 9 )N] 5 [H 4 P 2 V 3 W 15 o 62 ], the small molecule initiator is hydroxyethyl bromoisobutyrate, the connecting molecule is trihydroxymethylaminomethane, atom transfer radical polymerization is adopted, the monomer is styrene, and the polymer is polystyrene.

[0023] Polyoxometalate-polymer hybrid block copolymer is used as nanotube substrate material, and N,N-dimethylformamide is used as solvent to prepare polyoxometalate-polymer hybrid block copolymer Add 001×7 type strongly acidic styrene-based cation-exchange resin to a solution with a ratio of 2.5 mg / mL to N,N-dimethylformamide, which accounts for 30% of the volume of the solution, and the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com