Nylon 6 mineral fiber composite material for automobile engine cover lid and preparation method thereof

A technology for automobile engines and composite materials, which is applied in the field of nylon 6 mineral fiber composite materials and its preparation. It can solve problems such as product warping, affecting product assembly, and glass fiber exposure, and achieves the elimination of glass fiber exposure and good dimensional stability. The effect of improving the performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

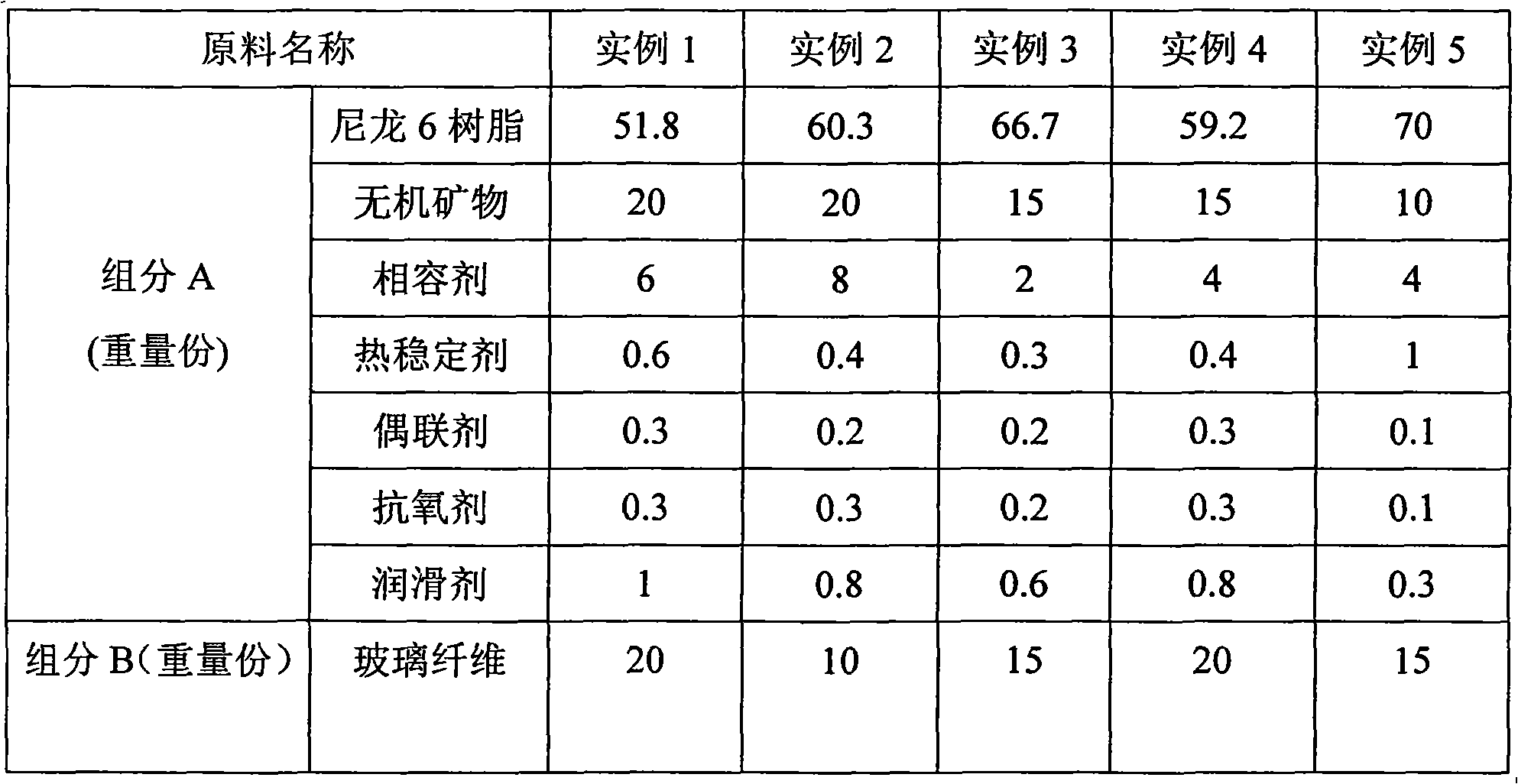

Embodiment 1

[0030] formula:

[0031] Nylon 6 resin, relative viscosity 2.4-2.8, 51.8 parts by weight; alkali-free short glass fiber, fiber length 3.5-4.2 mm, diameter 10-15 μm, 20 parts by weight; particle size 10-80 μm, main component is silicon Glass microspheres of acid salt, 20 parts by weight; Maleic anhydride grafted polyethylene, melt flow rate 1.3g / 10min (190 ℃ 2.16kg), 6 parts by weight; Thermal stabilizer is 0.6 parts by weight of cuprous iodide; The coupling agent is silane coupling agent KH550, 0.3 parts by weight; the antioxidant is 1098 antioxidant, 0.3 parts by weight; the lubricant is silicone powder, 1 part by weight.

Embodiment 2

[0033] formula:

[0034] Nylon 6 resin, relative viscosity 2.4-2.8, 60.3 parts by weight; alkali-free short glass fiber, fiber length 3.5-4.2 mm, diameter 10-15 μm, 10 parts by weight; talcum powder with particle size between 10-20 μm , 20 parts by weight; acrylate copolymer, melt flow rate 1.2g / 10min (190 ℃ 2.16kg), 8 parts by weight; thermal stabilizer is 0.4 parts by weight of cuprous iodide; silane coupling agent KH560, 0.2 parts by weight ; 168 antioxidant, 0.3 parts by weight; calcium stearate, 0.8 parts by weight.

Embodiment 3

[0036] formula:

[0037] Nylon 6 resin, relative viscosity 2.4-2.8, 66.7 parts by weight; non-alkali short glass fiber, fiber length is 3.5-4.2mm, diameter is 10-15 μm, 15 parts by weight; particle size is calcium carbonate between 10-20 μm , 15 parts by weight; hydrogenated SBS, melt flow rate 1.4g / 10min (190 ℃ 2.16kg), 2 parts by weight; thermal stabilizer is cuprous iodide 0.3 parts by weight; coupling agent is silane coupling agent KH560, 0.2 parts by weight; the antioxidant is 1098 antioxidant, 0.2 parts by weight; the lubricant is silicone powder, 0.6 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com