Carborundum fingered schottky contact nuclear battery

A Schottky contact and nuclear battery technology, which is applied in the field of microelectronics, can solve the problems of reduced energy conversion efficiency, low energy conversion efficiency, and large energy loss of incident particles, and achieves improved energy conversion efficiency, improved energy conversion efficiency, and process simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

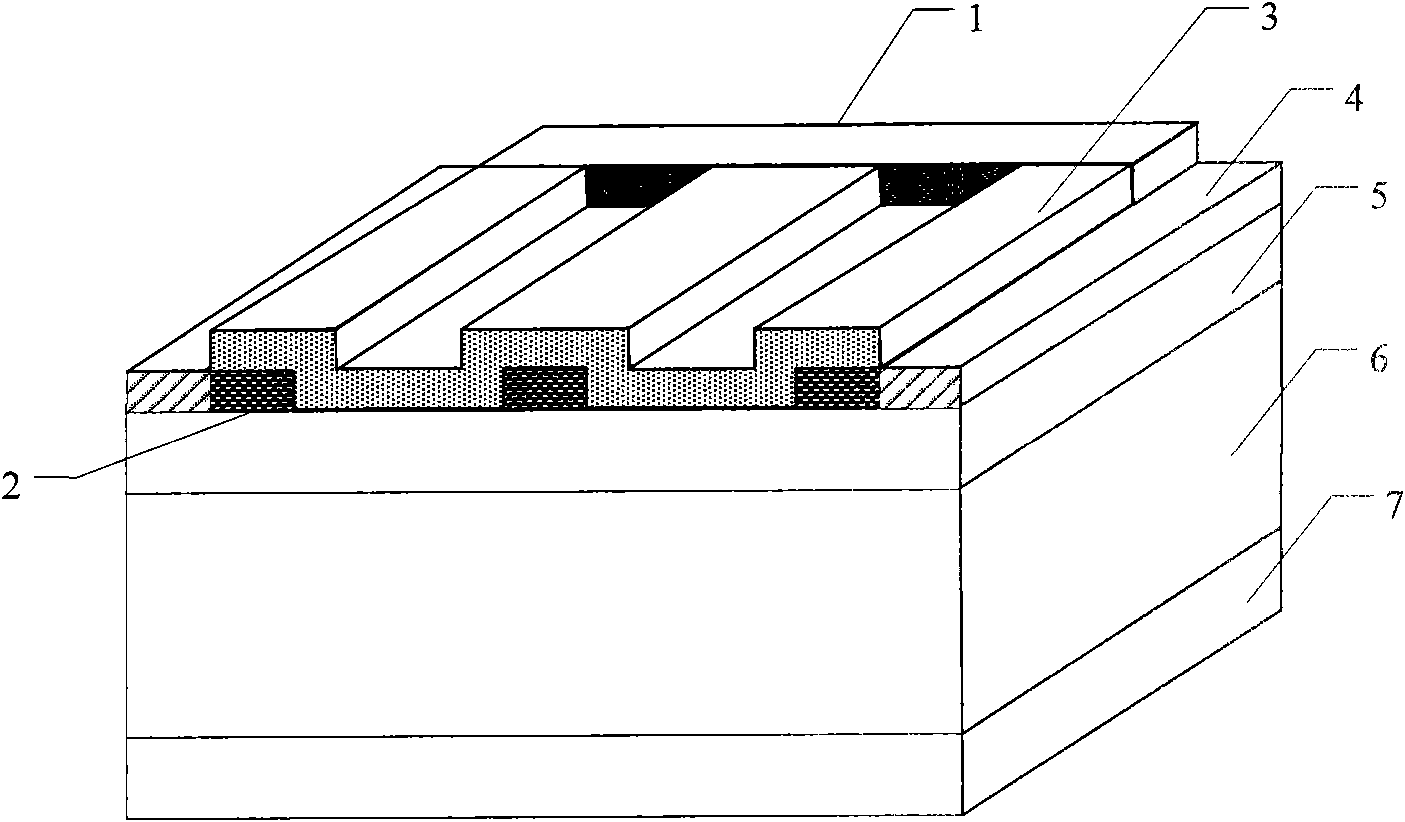

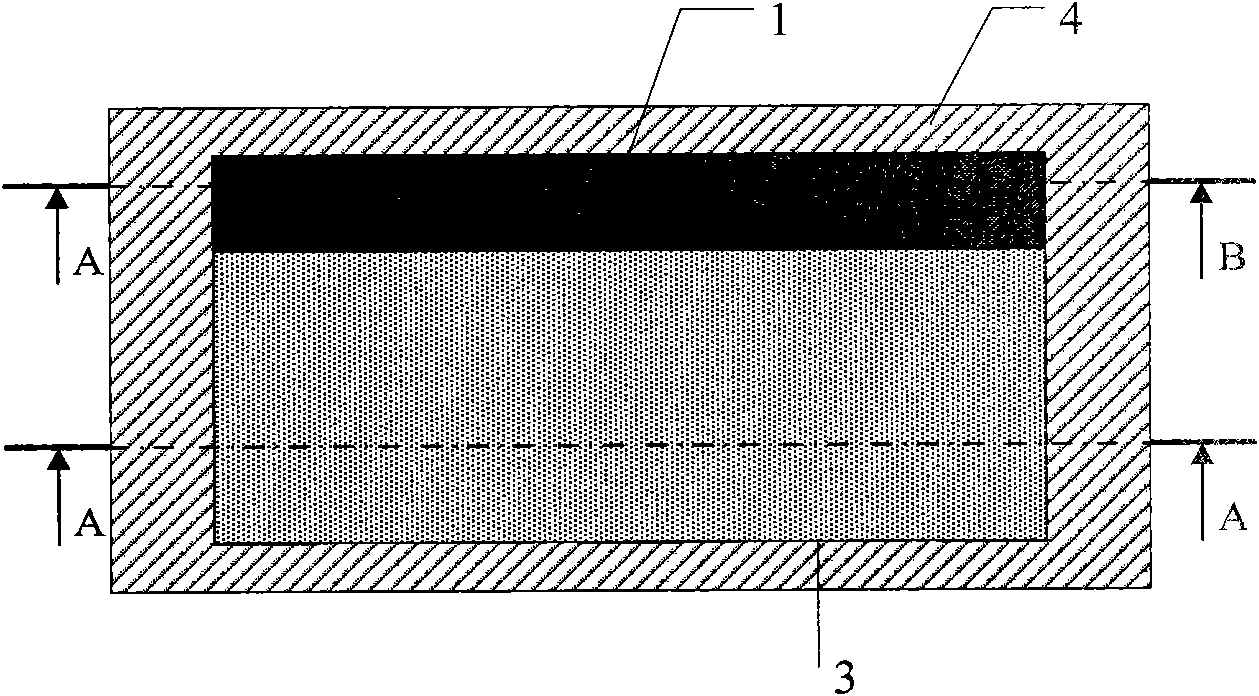

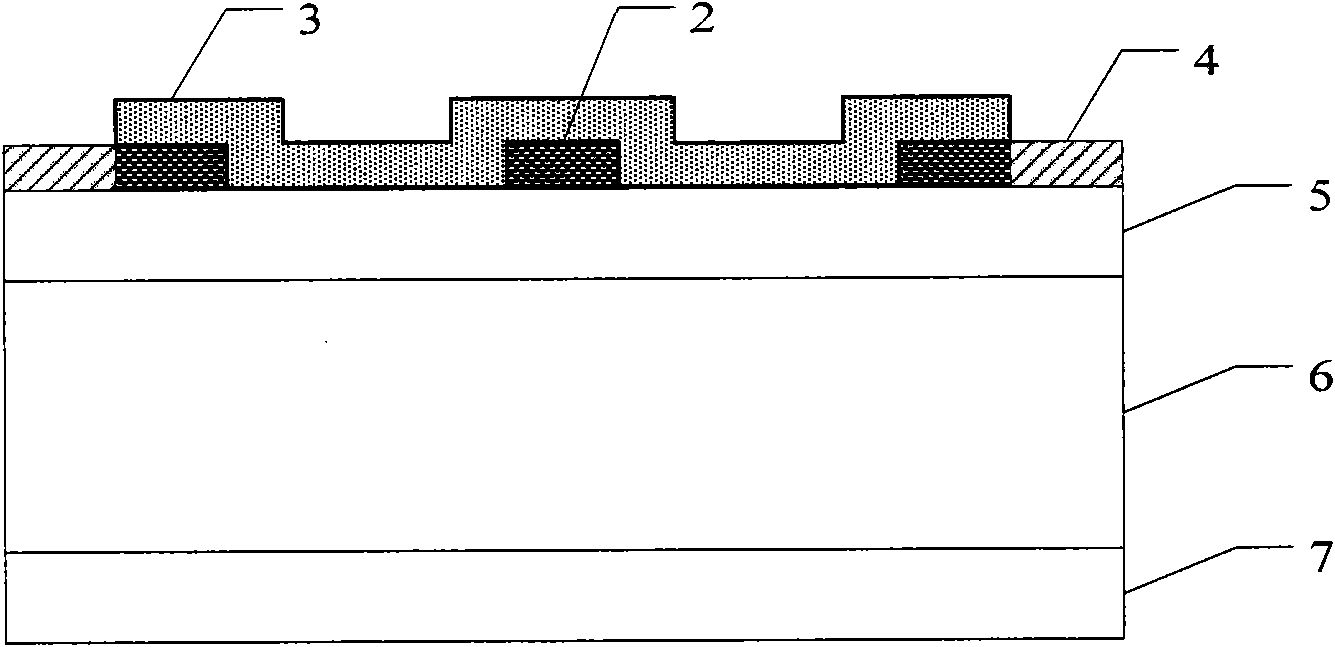

[0037] Step 1, epitaxial low-doped n-type epitaxial layer on SiC highly-doped n-type substrate, such as Image 6 a.

[0038] The selected doping concentration is 5 × 10 18 cm -3 The SiC highly doped n-type SiC substrate is used as the substrate 6. After cleaning, the epitaxial surface is grown with a thickness of about 3 μm by a low-pressure hot-wall chemical vapor deposition method. The doping concentration is 5 × 10 15 cm -3 The 4H-SiC low-doped epitaxial layer 5 has an epitaxial temperature of 1570° C., a pressure of 100 mbar, the reaction gases are silane and propane, and the carrier gas is pure hydrogen.

[0039] Step 2, Form SiO on the epitaxial layer 2 passivation layers such as Image 6 b.

[0040] The epitaxial substrate samples were subjected to dry oxygen oxidation for two hours at a temperature of 1100 ± 50 °C to form SiO 2 passivation layer.

[0041] In step 3, an ohmic contact is formed on the backside of the substrate, such as Image 6 c.

[0042] (3.1...

Embodiment 2

[0053] The first step is to epitaxy a low-doped n-type epitaxial layer on a SiC highly-doped n-type substrate.

[0054] The doping concentration is selected as 1×10 18 cm -3 The SiC highly doped n-type SiC substrate is used as the substrate 6. After cleaning, the epitaxial surface is grown with a thickness of about 3 μm by a low-pressure hot-wall chemical vapor deposition method. The doping concentration is 3 × 10 15 cm -3 The 4H-SiC low-doped epitaxial layer 5 has an epitaxial temperature of 1570° C., a pressure of 100 mbar, the reaction gases are silane and propane, and the carrier gas is pure hydrogen.

[0055] The second step is to form SiO on the epitaxial layer 2 passivation layer.

[0056] The epitaxial substrate samples were subjected to dry oxygen oxidation for two hours at a temperature of 1100 ± 50 °C to form SiO 2 passivation layer.

[0057] In the third step, an ohmic contact is formed on the backside of the substrate.

[0058] (3.1) etching a SiC layer wit...

Embodiment 3

[0069] Step A, epitaxial low-doped n-type epitaxial layer on SiC highly-doped n-type substrate.

[0070] The selected doping concentration is 5 × 10 17 cm -3 The SiC highly doped n-type SiC substrate is used as the substrate 6. After cleaning, the epitaxial surface is grown with a thickness of about 3 μm by a low-pressure hot-wall chemical vapor deposition method. The doping concentration is 1×10 15 cm -3 The 4H-SiC low-doped epitaxial layer 5 has an epitaxial temperature of 1570° C., a pressure of 100 mbar, the reaction gases are silane and propane, and the carrier gas is pure hydrogen.

[0071] Step B, forming SiO on the epitaxial layer 2 passivation layer.

[0072] The epitaxial samples were subjected to dry oxygen oxidation for two hours at a temperature of 1100 ± 50 °C to form SiO 2 passivation layer.

[0073] In step C, an ohmic contact is formed on the backside of the substrate.

[0074] (C1) etching a SiC layer with a thickness of 0.5 μm on the backside of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com