Equal-current synthetic high-power constant current power supply circuit

A constant current power supply, high power technology, applied in the direction of circuits, electrical components, laser components, etc., can solve problems such as output current imbalance, power tube damage, drive stability, poor reliability and safety, and improve reliability , enhance the effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

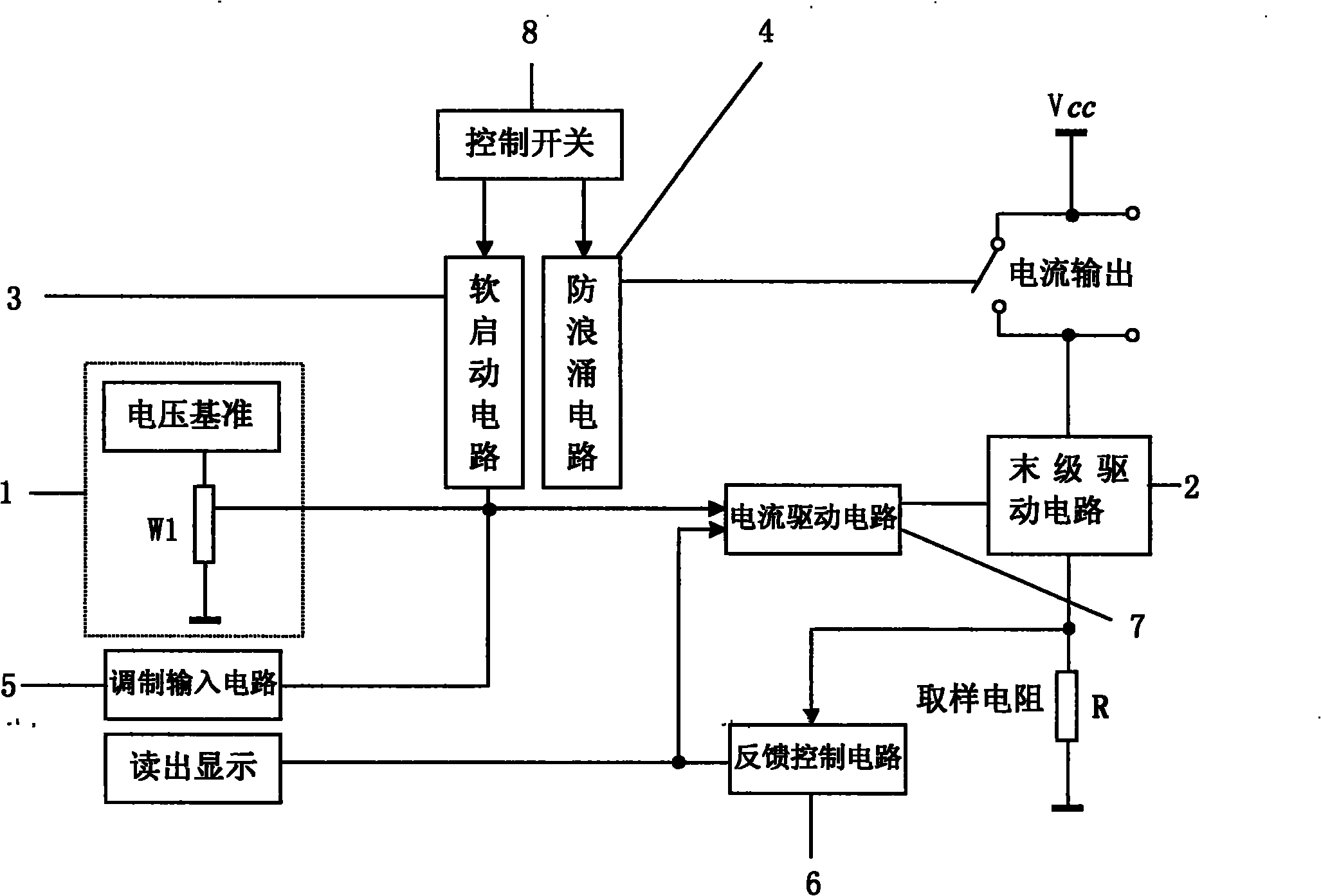

[0023] Such as figure 1 As shown, the current equalizing synthetic high-power constant-current power supply circuit of the present invention includes a voltage reference circuit 1, a final drive circuit 2, a soft-start circuit 3, an anti-surge circuit 4, a modulation input circuit 5, a feedback control circuit 6, and a current drive circuit. Circuit 7 and control switch 8; voltage reference circuit 1 is composed of a voltage reference LM336-2.5 and a 9.1 kohm resistor, which provides accurate and stable reference voltage for the circuit to control the output current and preset limit current. Potentiometer W1 is used to adjust the output current. The final drive circuit 2 outputs a set current, and adopts a method of connecting multiple MOS transistors in parallel, and the emitter of each MOS transistor is connected in series with a current sharing resistor. The current drive circuit 7 converts the control voltage into an output current. The feedback control circuit 6 realize...

Embodiment 2

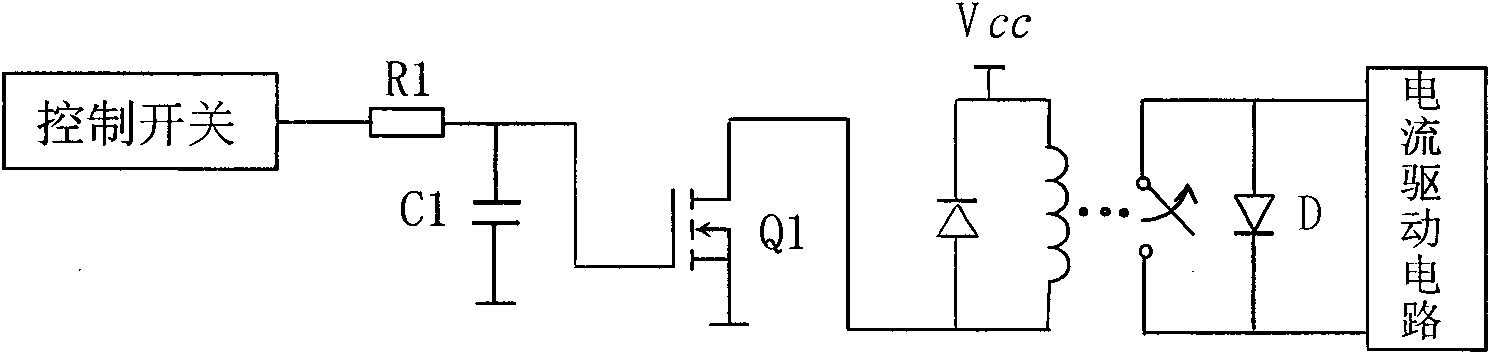

[0025] Such as figure 2 As shown, the anti-surge circuit 4 includes an RC charging circuit composed of a resistor R1 and a capacitor C1, an N-channel enhanced field effect transistor Q1, and a normally closed solid state relay. The gate of the field effect transistor Q1 is connected to the resistor R1 and the capacitor C1, the other end of the capacitor C1 is grounded, the drain of the field effect transistor Q1 is connected to the relay, and the source of the field effect transistor Q1 is grounded. The type of field effect transistor Q1 may be 2sk1458.

[0026] The working principle of the circuit is: the anode and cathode of the laser diode LD are connected in parallel with the two normally closed ends of the relay, so the cathode and anode of the laser diode LD are short-circuited and protected. When the driver is turned on, if the control switch is not turned on, the laser diode LD is still short-circuited. Only after the control switch 8 is turned on, the normally close...

Embodiment 3

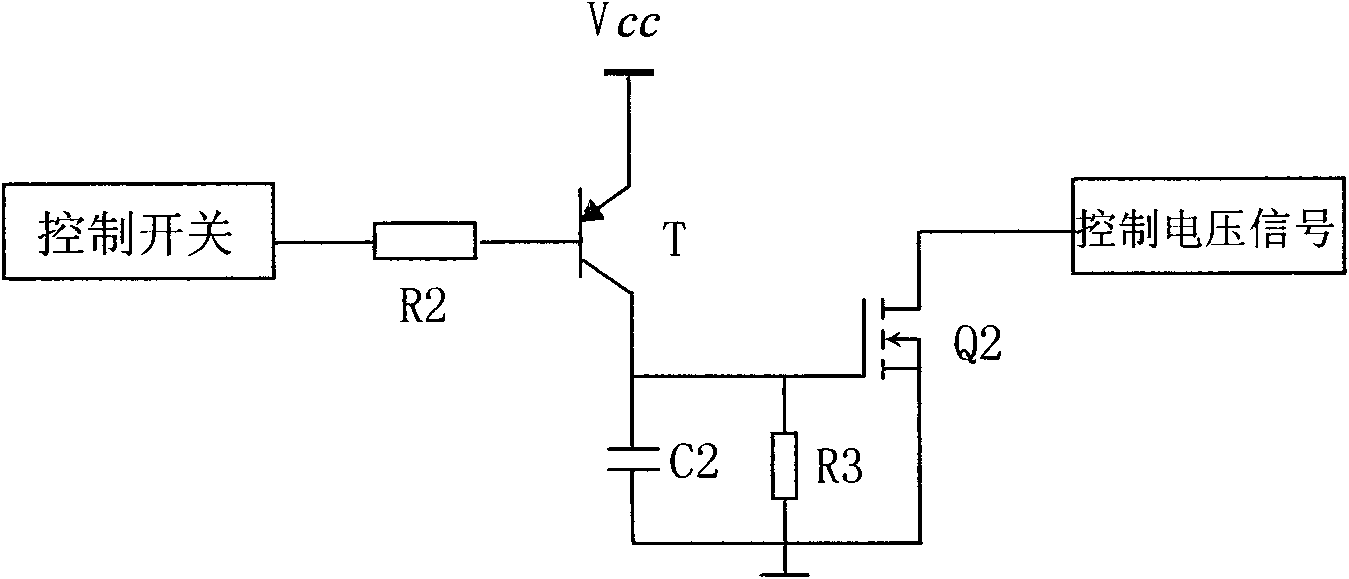

[0028] Such as image 3 As shown, the soft start circuit 3 includes a PNP transistor T, an RC discharge circuit composed of a resistor R3 and a capacitor C2, and an N-channel enhanced field effect transistor Q2. The gate of the field effect transistor Q2 is connected to the resistor R3 and the capacitor C2, and the other end of the resistor R3 and the capacitor C2 is grounded; the drain of the field effect transistor Q2 is connected to the control signal, and the source of the field effect transistor Q2 is connected to the ground; the base of the triode T The electrode is connected to the control switch 8 through the resistor R2, and the emitter of the triode T is connected to the working power supply V CC , the collector of the transistor T is connected to the gate of Q2.

[0029] Among them, the model of the triode T can be selected as 9012, and the model of the field effect transistor Q2 can be selected as 2sk1458.

[0030]The function of the soft start circuit is: after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com