Two-stage anaerobic-tower type filter chamber livestock/poultry wastewater treatment system and treatment process

A wastewater treatment system and wastewater treatment technology, applied in anaerobic digestion treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc. It is not easy to remove and other problems, and achieves the effect of great promotion and application value, strong adsorption capacity and strong removal capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

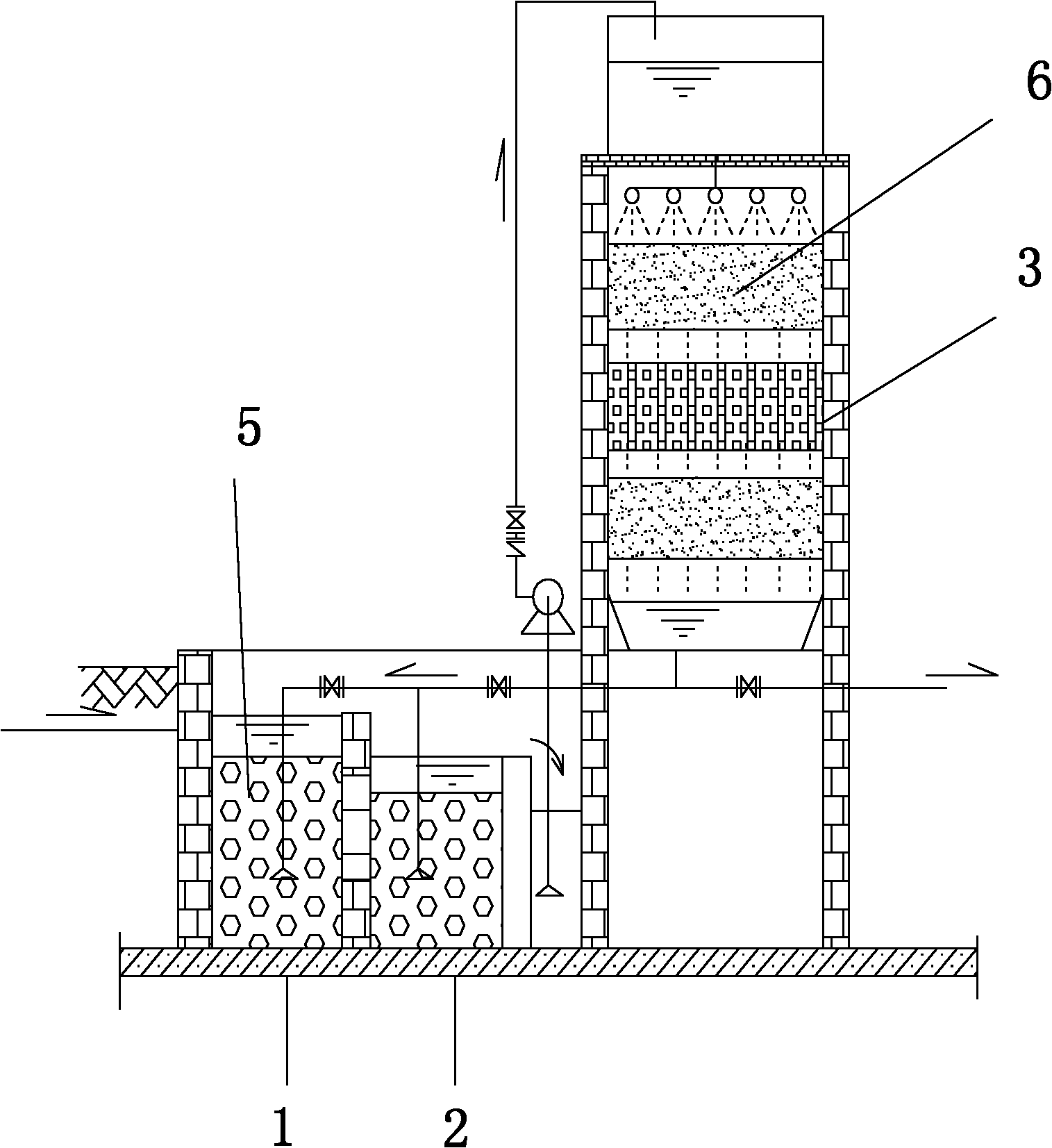

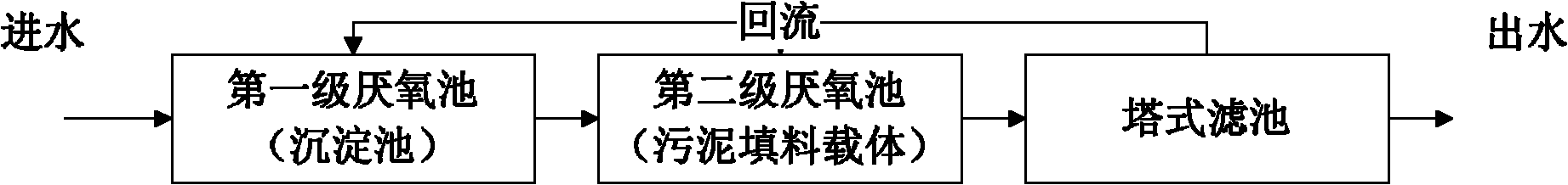

[0036] Two-stage anaerobic-tower filter wastewater treatment system, the wastewater inlet is connected to the first-stage anaerobic pool 1, the first-stage anaerobic pool 1 is connected to the second-stage anaerobic pool 2 through the outlet pipe, and the outlet pipe of the second-stage anaerobic pool is connected to the tower Type filter 3-phase connection ( figure 1 ).

[0037] Wastewater from a pig farm: influent COD Cr =986~1534mg / L, NH 4 + -N=130~409mg / L, TP=11.3~27.4mg / L, pH value 8.04~8.61, SS 100~300mg / L.

[0038] Pig wastewater is firstly treated with two stages of anaerobic treatment, with a design volume of 5m 3 and 5m 3 , set the hydraulic retention time (HRT) to be 3 days, fill the pool with artificially sintered sewage plant sludge filler 5 with a diameter of 2-5cm, and fill each filler with 2m 3 . The sludge filler sintering process is as follows: the weight percentage of sludge usage is 80%, the weight percentage of fly ash and clay is 10% each, the firi...

Embodiment 2

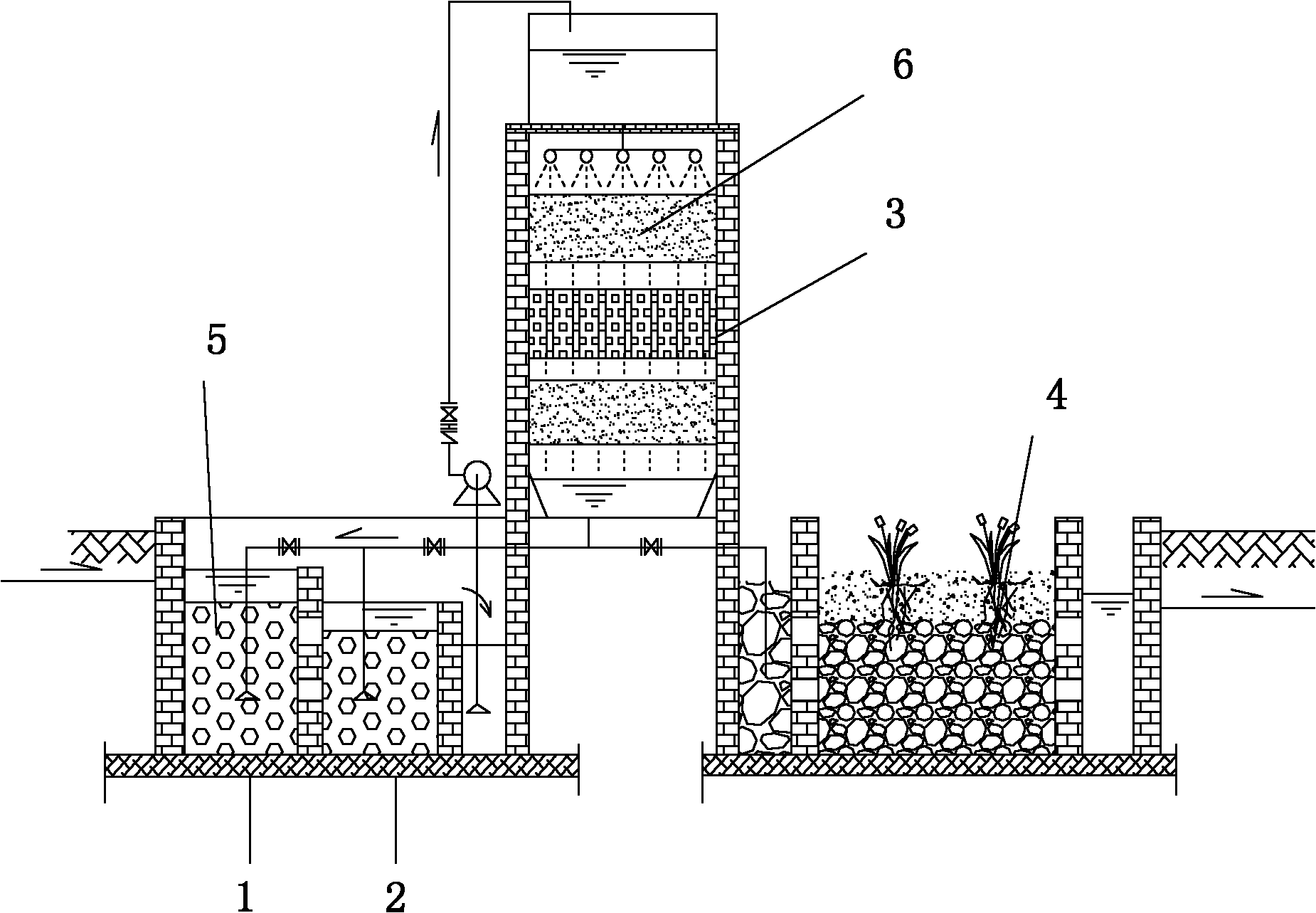

[0041] Two-stage anaerobic-tower filter wastewater treatment system, the wastewater inlet is connected to the first-stage anaerobic pool 1, the first-stage anaerobic pool 1 is connected to the second-stage anaerobic pool 2 through the outlet pipe, and the outlet pipe of the second-stage anaerobic pool is connected to the tower Type filter 3 is connected, and the water outlet of tower filter 3 is connected with gravel bed artificial wetland 4 ( figure 2 ).

[0042] Wastewater from a cattle farm: influent COD Cr =890~2100mg / L, NH 4 + -N=230-550 mg / L, TP=21.2-48.0 mg / L, pH value 7.04-7.81, SS 120-300 mg / L.

[0043] Pig wastewater is firstly treated with two stages of anaerobic treatment, with a design volume of 5m 3 and 8m 3 , the hydraulic retention time (HRT) is set to 4 days, and the pool is filled with artificially sintered sewage plant sludge spherical fillers with a diameter of 3-5cm, and the fillers are filled with 2m respectively. 3 and 4m 3 . The sludge filler s...

Embodiment 3

[0046] Two-stage anaerobic-tower filter wastewater treatment system, basic structure is the same as embodiment 2.

[0047] Wastewater from a pig farm: influent COD Cr =986~1534mg / L, NH 4 + -N=130~409mg / L, TP=11.3~27.4mg / L, pH value 8.04~8.61, SS 100~300mg / L.

[0048] Pig wastewater is firstly treated with two stages of anaerobic treatment, with a design volume of 5m 3 and 5m 3 , set the hydraulic retention time (HRT) to be 5 days, fill the pool with artificially sintered sewage plant sludge filler with a diameter of 2-5cm, and fill each filler with 2m 3 . The sludge filler sintering process is as follows: the weight percentage of sludge usage is 80%, the weight percentage of fly ash and clay is 10% each, the firing temperature is 1000°C, and the holding time is 2h. After two-stage anaerobic treatment, the COD in water Cr , the removal effect of SS and TP is remarkable, and the removal efficiency is between 40% and 65%.

[0049] Use the pump force to lift the effluent f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com