Method for producing recombinant protein A

A technology of recombinant protein and protein, which is applied in the field of high-density fermentation and protein separation and purification, to achieve the effects of low production cost, easy amplification, and high binding activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Shake flask culture of genetically engineered bacteria

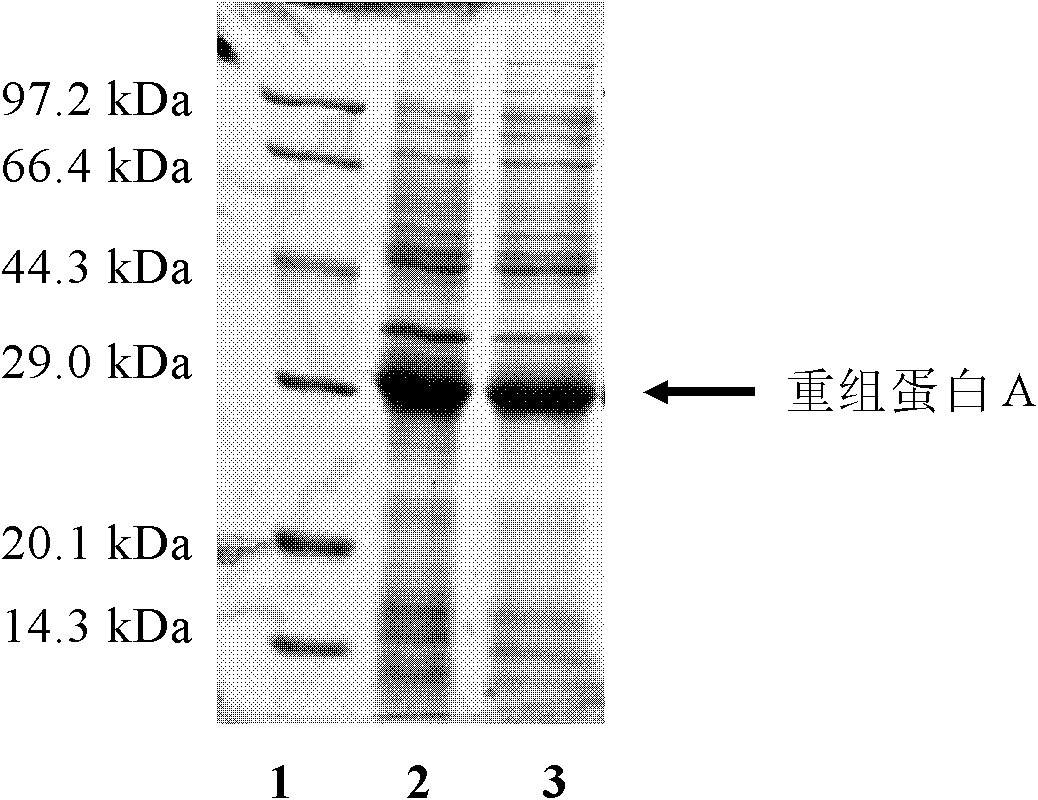

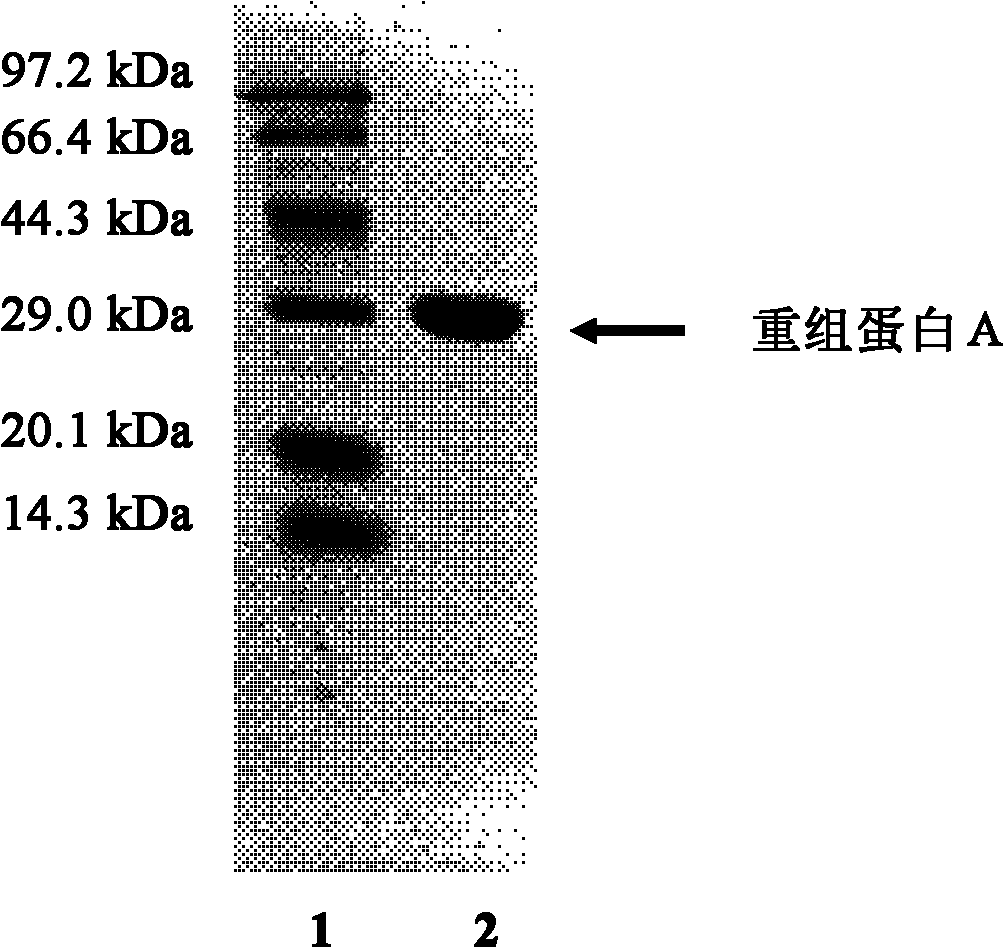

[0026] The genetically engineered bacteria expressing protein A were inoculated in 20 mL of LB liquid medium, and cultured overnight in a constant temperature shaker at 37° C. and 200 rpm. Inoculate the activated bacteria in 100 mL LB liquid medium according to the inoculum amount of 1%. Cultivate at 37°C, 200rpm for 3-4 hours, until the cell OD 600nm When it reaches 0.5-1, add IPTG to 0.2mM or add lactose to 1g / L, and continue to cultivate for 5-7 hours. SDS-PAGE detection confirmed the expression of recombinant protein A.

[0027] 2. High-density fermentation expression of recombinant protein A

[0028] (1) Configuration of fermentation medium

[0029] After sterilizing glucose (or glycerol), peptone, yeast extract, inorganic salts, and trace elements respectively, prepare a basic medium with the following final concentrations: 10-20g / L peptone, 5-10g / L yeast extract, 20 -50mM Na 2 HPO 4 , 20-50mM KH ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com