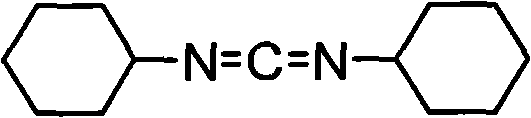

Process for preparing N,N'-dicyclohexyl carbodiimide by regeneration method

A dicyclohexylcarbodiimide, production process technology, applied in the field of N, can solve environmental problems such as pollution, waste of raw materials, etc., and achieve the effect of convenient operation, easy acquisition, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

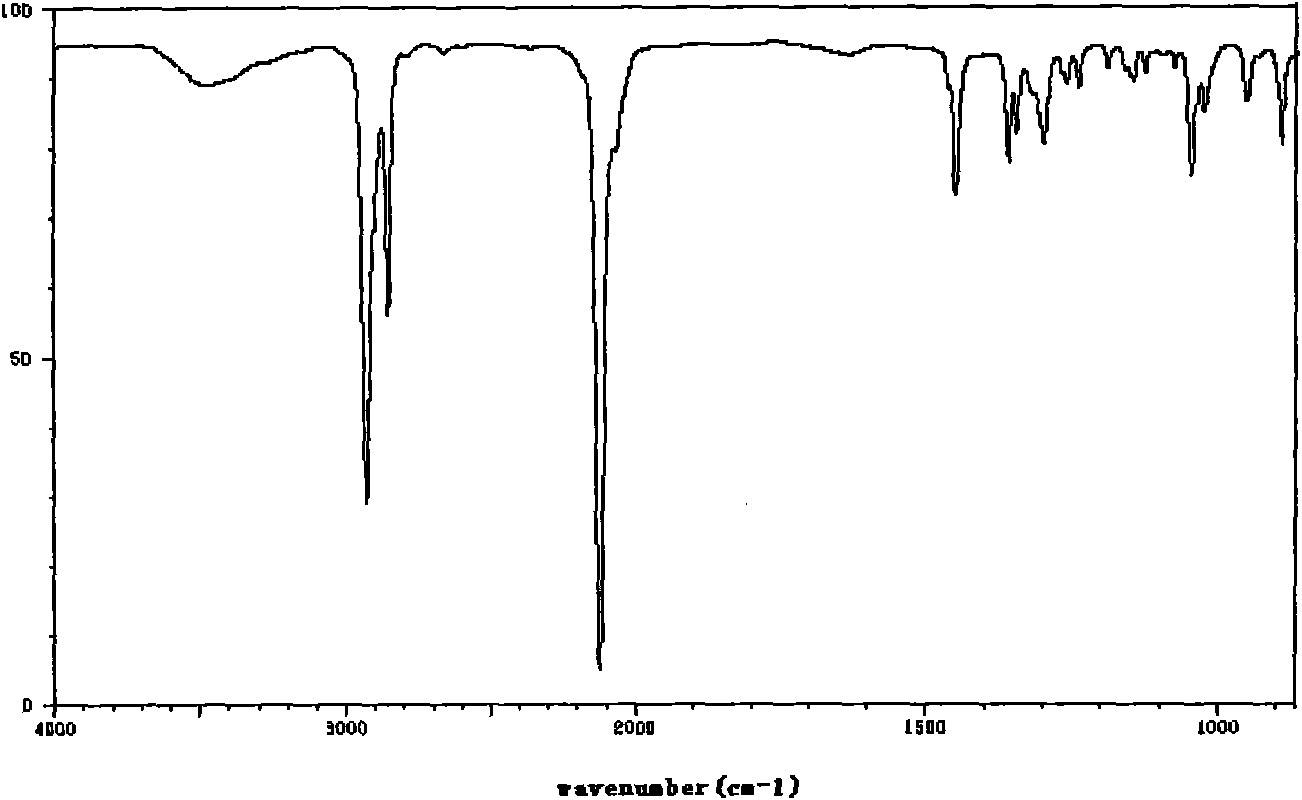

Image

Examples

Embodiment 1

[0025] Put 5.0kg of N, N'-dicyclohexylurea (DCU) raw materials into alkaline aqueous solution and soak three times to wash away the water-soluble impurities present in the raw materials. The soaked raw material was centrifugally dehydrated, put into a vacuum drying oven at 60° C., and dried to constant weight. The raw materials after constant weight are put into the polypropylene packing bag for standby.

[0026] Weigh 40.00 g of dried DCU, weigh 175.00 g of dichloromethane, add the two into a three-necked flask, weigh 35.50 g of phosphorus oxychloride, and add it to a 250 ml dropping funnel. Turn on the stirring device, then add phosphorus oxychloride dropwise to the reaction system, keep stirring for 2 hours after the addition, and keep the temperature between 40°C and 42°C during the reaction; pour the reaction solution into the dropping funnel, Then add 160g liquid industrial caustic soda (about 30%) in the there-necked flask, add 275ml distilled water. Turn on the stirr...

Embodiment 2

[0028] Weigh 40.00 g of dried DCU and 180.00 g of tetrahydrofuran, respectively add them into a three-necked flask, weigh 35.50 g of phosphorus oxychloride and add them into a 250 ml dropping funnel. Turn on the stirring device, then add phosphorus oxychloride dropwise to the reaction system, keep stirring for 2 hours after the addition, and keep the temperature between 40°C and 42°C during the reaction; pour the reaction solution into the dropping funnel, Then add 160g liquid industrial caustic soda (about 30%) in the there-necked flask, add 275ml distilled water. Turn on the stirring, add the reaction solution dropwise, continue stirring for 10 minutes after the addition, and keep the temperature below 40°C. Finally, the product was poured into a 1L separatory funnel, and the layers were allowed to stand. Release the lower organic phase, put it into a rotary evaporator to concentrate and crystallize to obtain the DCC product. The regeneration rate is 60%, and the DCC conte...

Embodiment 3

[0030] Weigh 40.00 g of dried DCU, weigh 150.00 g of acetonitrile, add the two into a three-necked flask, weigh 35.50 g of phosphorus oxychloride, and add it to a 250 ml dropping funnel. Turn on the stirring device, then add phosphorus oxychloride dropwise to the reaction system, keep stirring for 2 hours after the addition, and keep the temperature between 40°C and 42°C during the reaction; pour the reaction solution into the dropping funnel, Then add 130g industrial sodium carbonate in the there-necked flask, add 250ml distilled water. Turn on the stirring, add the reaction solution dropwise, continue stirring for 10 minutes after the addition, and keep the temperature below 40°C. Finally, the product was poured into a 1L separatory funnel, and the layers were allowed to stand. Release the lower organic phase, put it into a rotary evaporator to concentrate and crystallize to obtain the DCC product. The regeneration rate is 70%, and the DCC content of the product is 99.8%. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com