High glowing filament ignition temperature inflaming retarding reinforced poly(butylene terephthalate)

A technology of polybutylene terephthalate and light-off temperature, which is applied in the field of flame-retardant reinforced polybutylene terephthalate with high glow wire light-off temperature, which can solve the problems of performance degradation, material cost increase, and price Advanced problems, to achieve the effect of simple preparation method, low material cost and high ignition temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

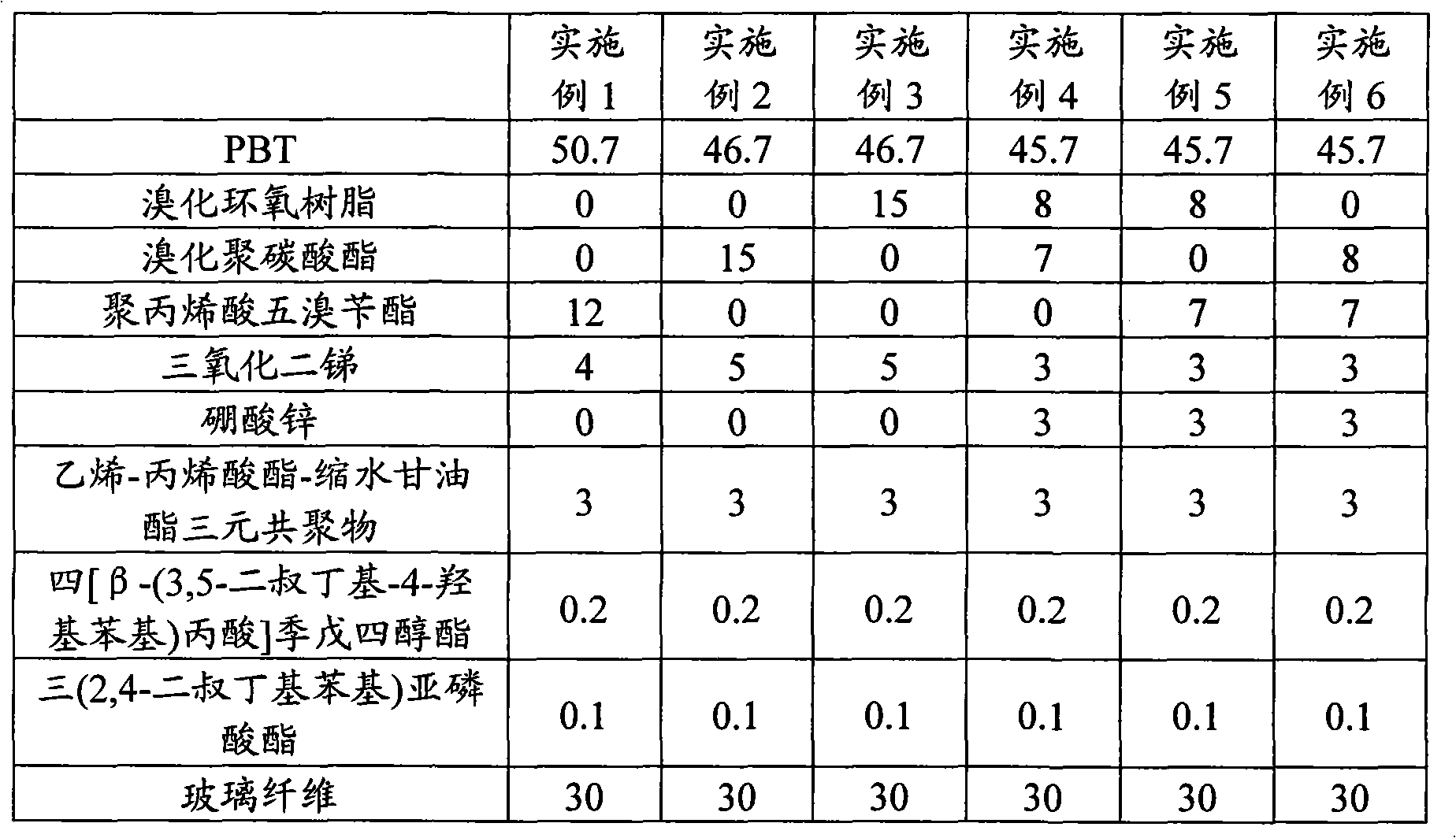

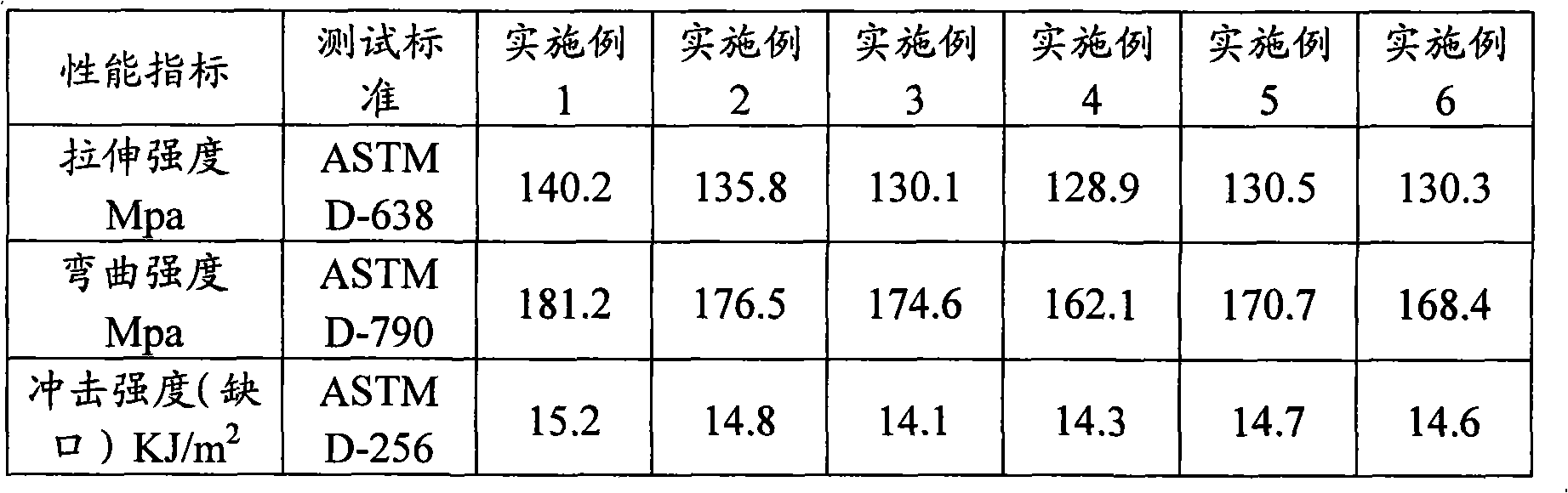

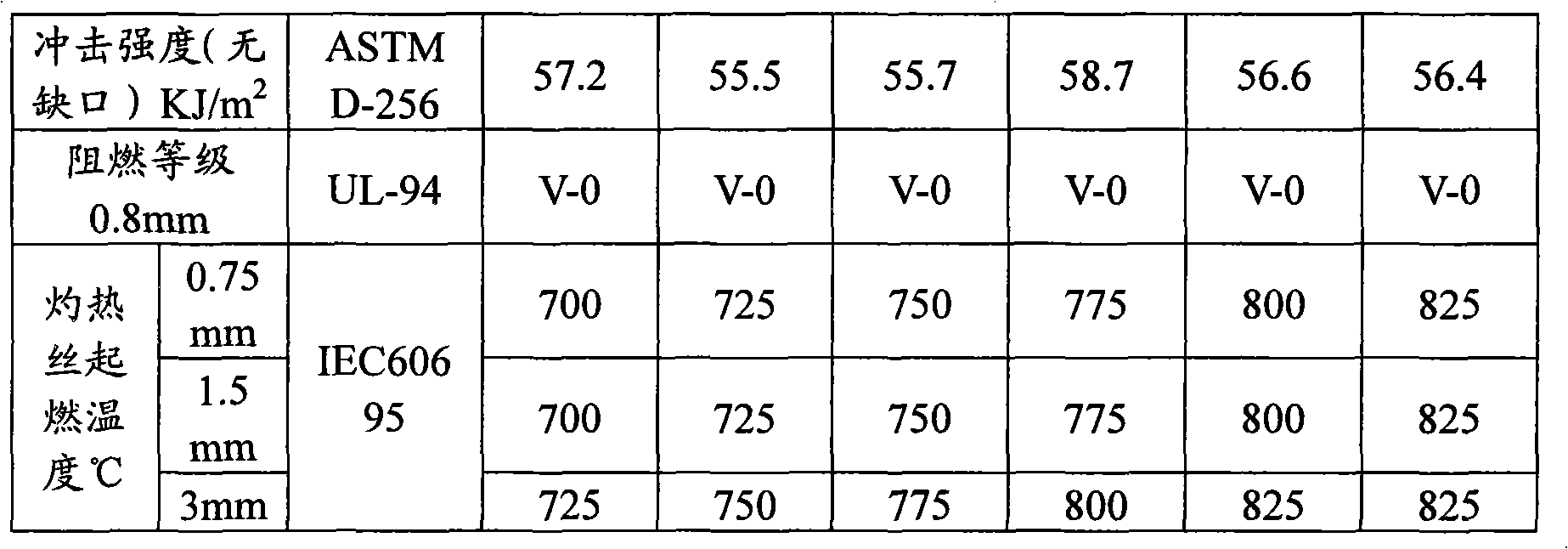

Embodiment 1~6

[0038] Dry polybutylene terephthalate (PBT) at 110°C for 4 hours, add flame retardant, synergist, toughener, primary antioxidant, auxiliary antioxidant and dried PBT to the Mix at high speed in a high-speed mixer for 4 minutes to make it evenly mixed to obtain a mixture. Put the above-mentioned mixture into a feeder with metering function, and feed the material quantitatively into the twin-screw extrusion granulator through the feeder, and at the same time, the glass fiber Feed through the middle feeding device of the twin-screw extrusion granulator, and obtain pellets through twin-screw extrusion, stranding, water cooling and pelletizing, that is, high glow wire ignition temperature flame-retardant reinforced polybutylene terephthalate Glycol esters.

[0039] The above-mentioned pellets were dried in an oven at 110° C. for 4 hours, and then test specimens were prepared using an injection molding machine.

[0040] The raw materials used are:

[0041] PBT adopts Nantong Xingc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com