Adhesive for laminated steel and preparation method thereof

A technology of adhesive and laminated iron, applied in the direction of adhesive type, polyurea/polyurethane adhesive, polymer adhesive additive, etc., can solve the problem of poor temperature resistance, acid and alkali corrosion resistance, etc. problems, to achieve good temperature resistance and corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

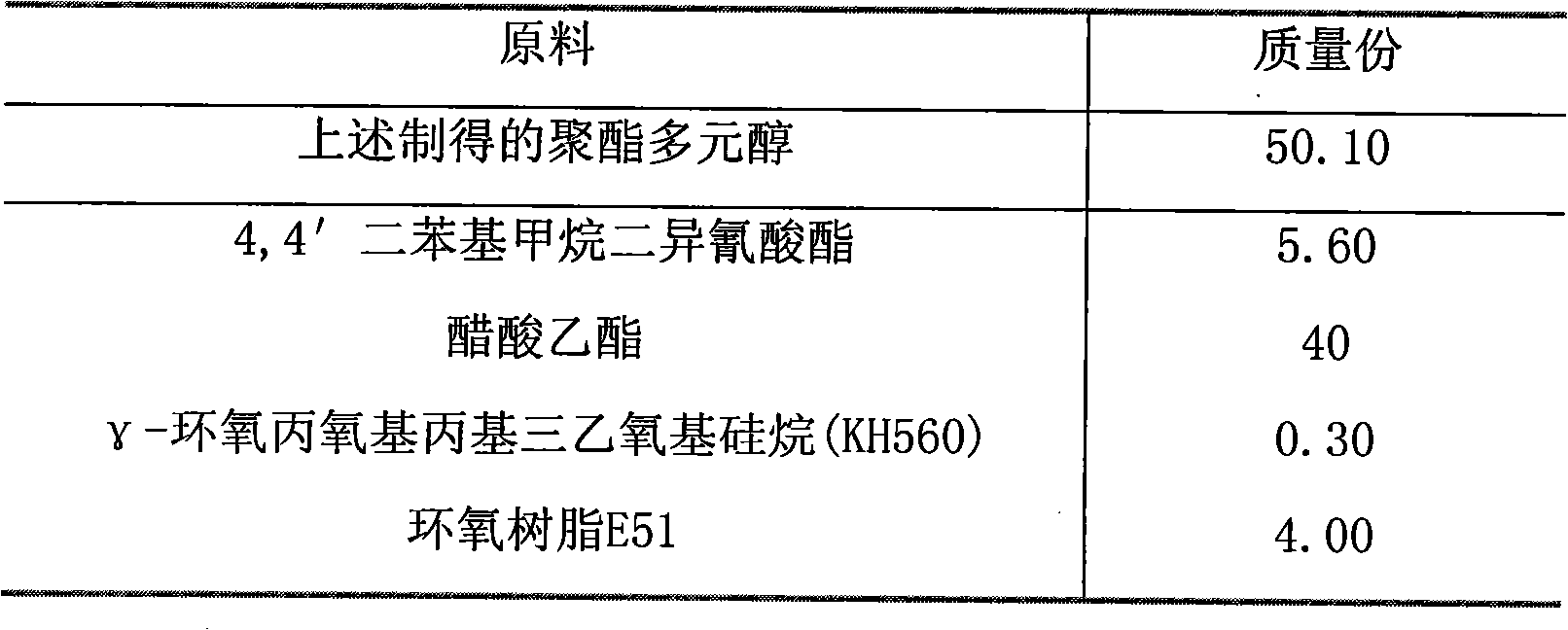

[0018] This embodiment provides an adhesive for laminating iron, which is used in laminating iron. In terms of weight percentage, the adhesive is 40-55% polyester polyol, 3-6% 4,4 'Diphenylmethane diisocyanate, 40-50% of environmentally friendly organic solvents, 0.1-0.5% of γ-glycidoxypropyl triethoxysilane and 4-6% of bisphenol A epoxy resin as raw material;

[0019] React polyester polyol, 4,4' diphenylmethane diisocyanate and environment-friendly organic solvent at 70-90°C for 3-4 hours, add γ-glycidoxypropyl triethoxysilane, The bisphenol A type epoxy resin can be used to prepare an adhesive with a solid content of 50% to 60%, a viscosity of 3000mPa·s to 5000mPa·s, and a hydroxyl value of 10 to 20mgKOH / g.

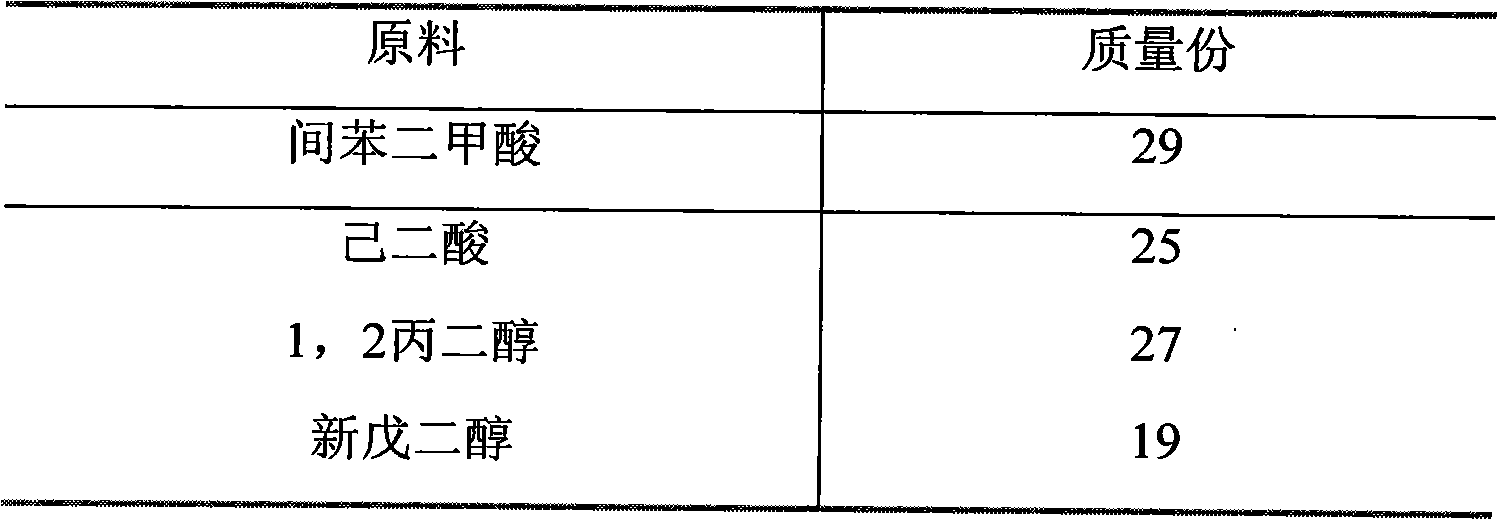

[0020] The polyester polyol used in the above-mentioned binder, by weight percentage, with 20~30% isophthalic acid, 20~30% 1,2 propanediol, 25~35% adipic acid and 15~25% % of neopentyl glycol as a raw material, the polyester polyol made from each raw material through...

Embodiment 2

[0030] This embodiment provides an adhesive for laminating iron, which is used in laminating iron. The adhesive is prepared according to the following steps:

[0031] (1) Prepare polyester polyol, get and prepare each raw material of polyester polyol according to the formula of the table:

[0032]

[0033] The operation steps of preparing polyester polyol are:

[0034] (1) primary esterification:

[0035] Add 29 parts by mass of isophthalic acid, 27 parts by mass of 1,2 propylene glycol, 25 parts by mass of adipic acid, and 19 parts by mass of neopentyl glycol into the polyester synthesis kettle, heat up to 210-230°C, Reacted for 3 hours; in the primary esterification process, the amount of water output was stable (accounting for 0.5-1.0% / hour of input raw material gross weight), distilled water 12 mass parts, the esterification reaction was completed, and the acid value of the measured product was 17mgKOH / g ( Meet the acid value ≤ 20mgKOH / g);

[0036] (2) Polycondensati...

Embodiment 3

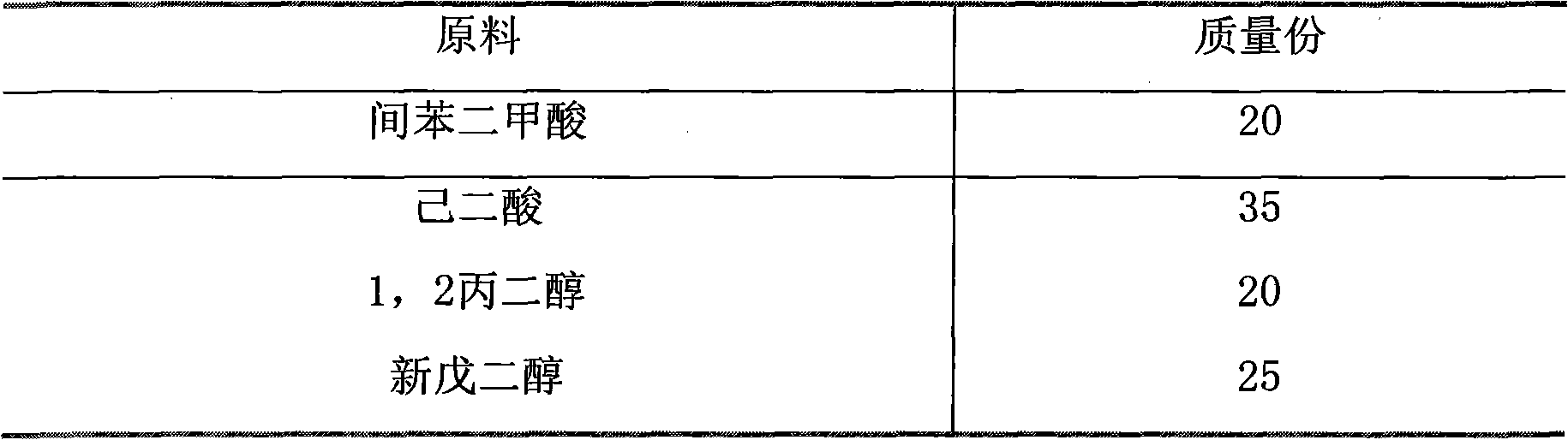

[0045] (1) Prepare polyester polyol, get and prepare each raw material of polyester polyol according to the formula of the table:

[0046]

[0047] The operation steps of preparing polyester polyol are:

[0048] (1) primary esterification:

[0049] Add 20 parts by mass of isophthalic acid, 20 parts by mass of 1,2 propylene glycol, 35 parts by mass of adipic acid, and 25 parts by mass of neopentyl glycol into the polyester synthesis kettle, and raise the temperature to 210-230°C, React for 2.5 hours; during the first esterification process, keep the water output stable (0.5~1.0% / hour), and distill 13 parts by mass of water; after the esterification reaction is completed, the acid value of the measured product is 16mgKOH / g (according to the acid value≤20mgKOH / g);

[0050] (2) Polycondensation reaction:

[0051] After the first esterification is completed, vacuumize the inside of the polyester synthesis kettle, the vacuum degree is from -0.02Mpa to -0.04Mpa, and after 2 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com