Method and device for producing biological butanol with straw-like materials or agricultural and forestry wastes

A technology for agricultural and forestry waste and bio-butanol is applied in the field of devices for producing bio-butanol from straw materials or agricultural and forestry waste, and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

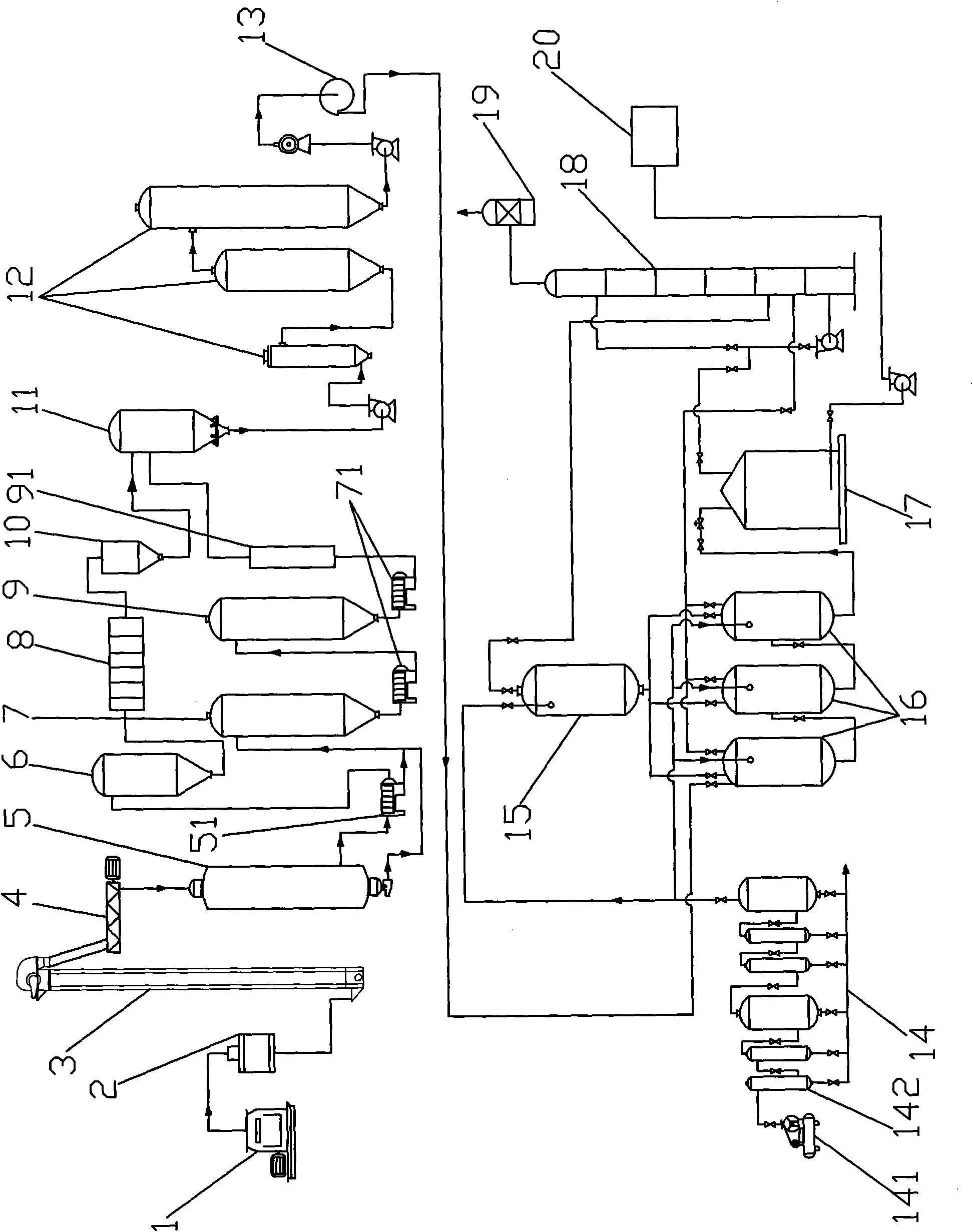

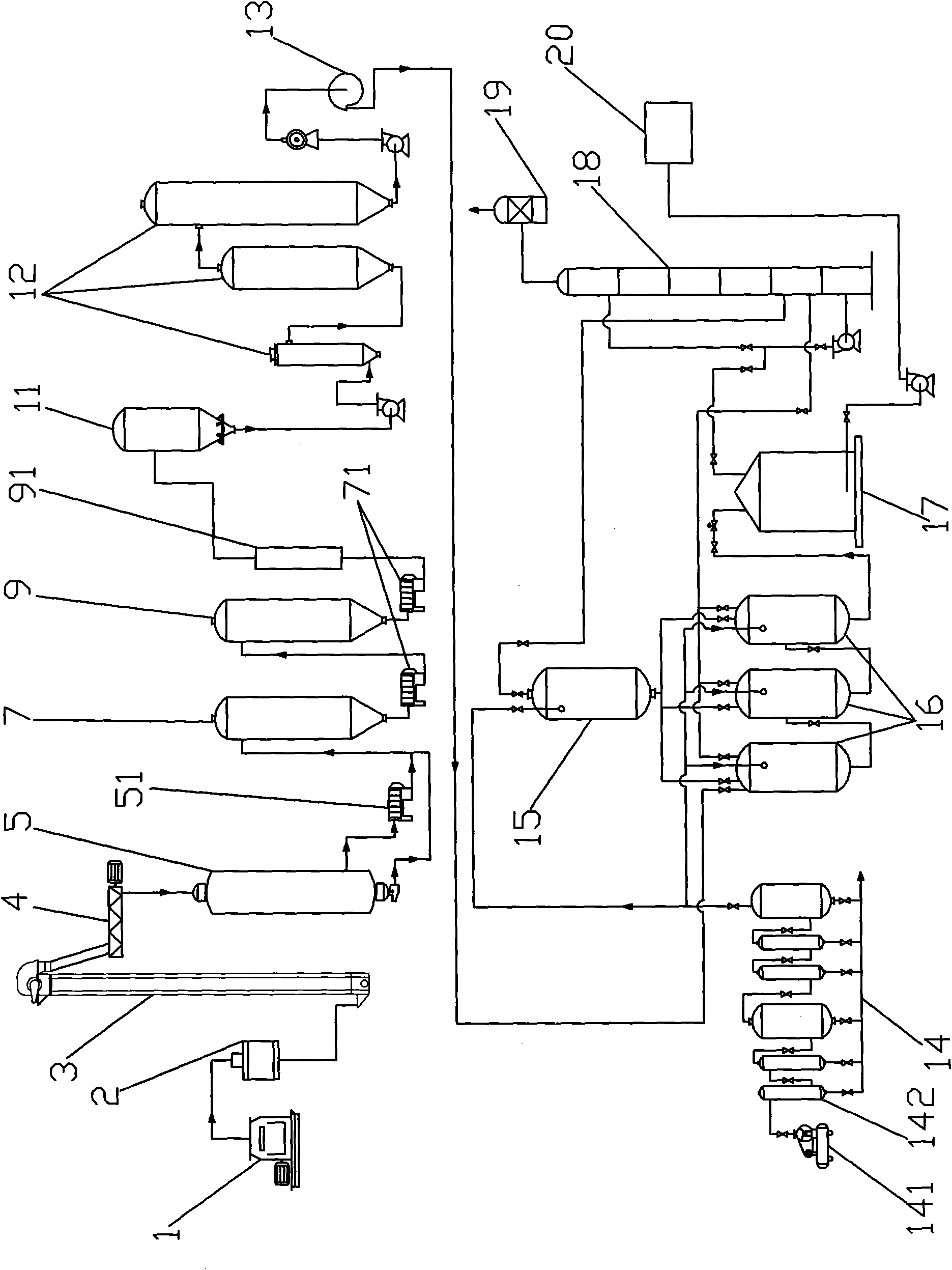

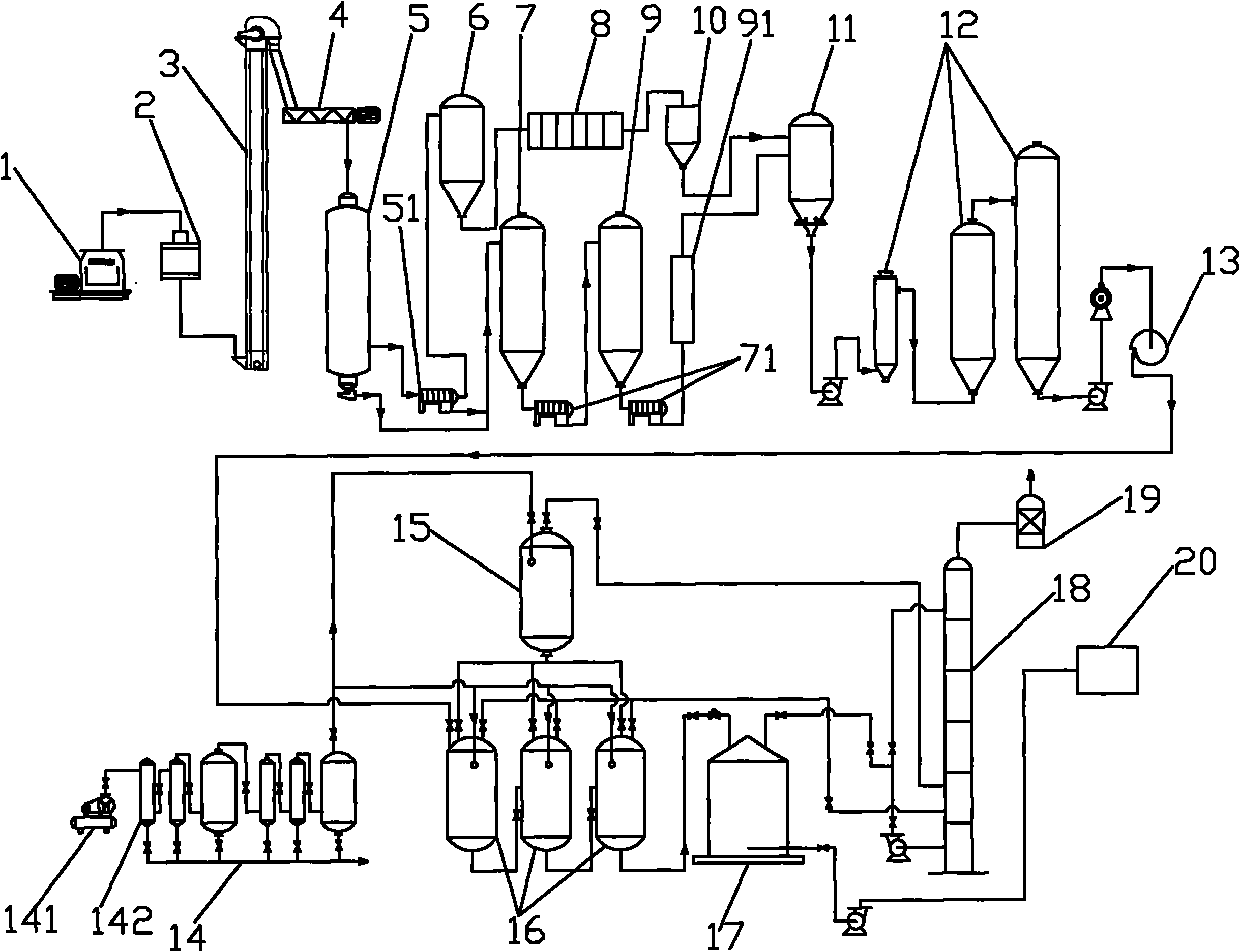

[0023] Embodiment 1: as figure 1 As shown, the device for producing bio-butanol from straw materials or agricultural and forestry wastes includes a crushing device 1, a washing device 2, a hoist 3, a conveying device 4, a hydrolysis pot 5, a solid-liquid separation device 51, and a neutralization tank connected in sequence 7. Decolorization tank 9, ion exchange device 91, batching tank 11, sterilizing device 12, heat exchanger 13, three series-connected fermentation tanks 16, temporary storage tank 17, rectification device 20, liquid outlet of solid-liquid separation device 51 Connected with the neutralization tank 7, the solid outlet of the solid-liquid separation device 51 is connected with the batching tank 11 through the neutralization tank 6, the enzymolysis device 8 and the decolorization tank 10, the neutralization tank 7 and the decolorization tank 9 and the decolorization tank 9 and the ion exchange tank All are provided with solid-liquid separation device 71 between ...

Embodiment 2

[0027] Embodiment 2: as figure 1 As shown, the device for producing bio-butanol from straw materials or agricultural and forestry wastes is the same as that in Example 1.

[0028] The method for producing bio-butanol from straw materials or agricultural and forestry wastes comprises the following steps: (1) First, the sunflower straw is cleaned, then crushed by a crushing device 1, washed by a water washing device 2, sent to a hydrolysis pot 5, and then added Phosphoric acid with a mass percentage concentration of 5% is hydrolyzed, and the amount of phosphoric acid added is 6 times the weight of sunflower stalks, and then 110 ° C hot steam is passed through for 6 hours for hydrolysis, and the solid-liquid mixture after hydrolysis is separated into hydrolyzed liquid and solid; Add calcium carbonate to the hydrolyzate to neutralize the pH value to 5, then separate the solid from the liquid, add activated carbon to the liquid part for adsorption and decolorization, and then separ...

Embodiment 3

[0031] Embodiment 3: as figure 1 As shown, the device for producing bio-butanol from straw materials or agricultural and forestry wastes is the same as that in Example 1.

[0032] The method for producing bio-butanol from straw materials or agricultural and forestry wastes comprises the following steps: (1) first cleaning branches and sawdust, then crushing them through a crushing device 1, and then washing them with water in a washing device 2 and sending them into a hydrolysis pot 5, adding Soak in hot water at 98°C for 1 hour, then add oxalic acid with a mass percentage concentration of 10% for hydrolysis. The solid-liquid separation of the liquid mixture is divided into hydrolyzed liquid and solid matter; adding potassium carbonate and potassium hydroxide to the hydrolyzed liquid to neutralize the pH value to 7, then separating the solid-liquid, adding activated carbon to the liquid part for adsorption and decolorization, and then separating the solid-liquid, and the liqui...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com