Liquid crystal machine-readable anti-false element

A technology of anti-counterfeiting components and liquid crystals, applied in optics, printing, instruments, etc., can solve problems such as insufficient anti-counterfeiting measures to ensure anti-counterfeiting effects, lowering the anti-counterfeiting level of securities and anti-counterfeiting marks, and public confusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

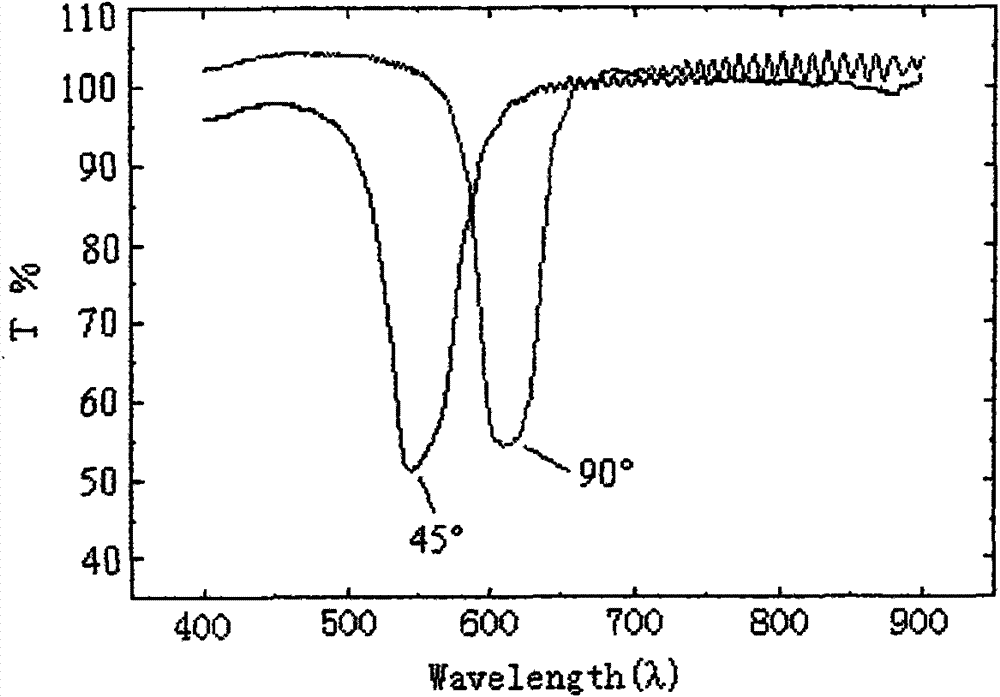

[0052] Three kinds of nematic liquid crystal prepolymer materials described in US6806930 (its structural formulas are shown in formulas I-1, I-2 and I-3 respectively), chiral substance ST31L (its structural formulas are shown in formula II) , IRGACURE photoinitiator of Ciba-Geigy company, anisole, cyclopentanone are mixed mutually, make cholesteric liquid crystal solution (mass percentage range of various materials is as shown in Table 1), wherein chiral substance accounts for solid component 3.5wt.% of the total amount;

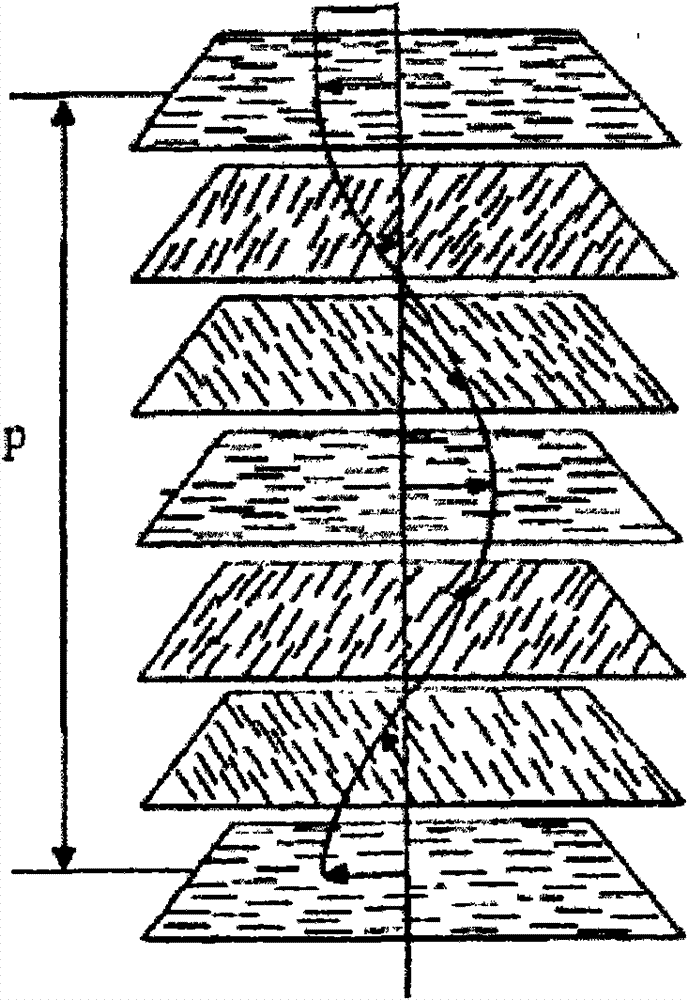

[0053] Coat the above-mentioned cholesteric liquid crystal solution on the transparent PET film (substrate layer) 1 with a wire rod, dry and remove the solvent, and cure the dried coating with ultraviolet light under a nitrogen atmosphere to form a layer of cholesteric liquid crystal. Layer 211;

[0054] Coat the above-mentioned cholesteric liquid crystal solution again in the part of this cholesteric liquid crystal layer, dry and solidify the coating to fo...

Embodiment 2

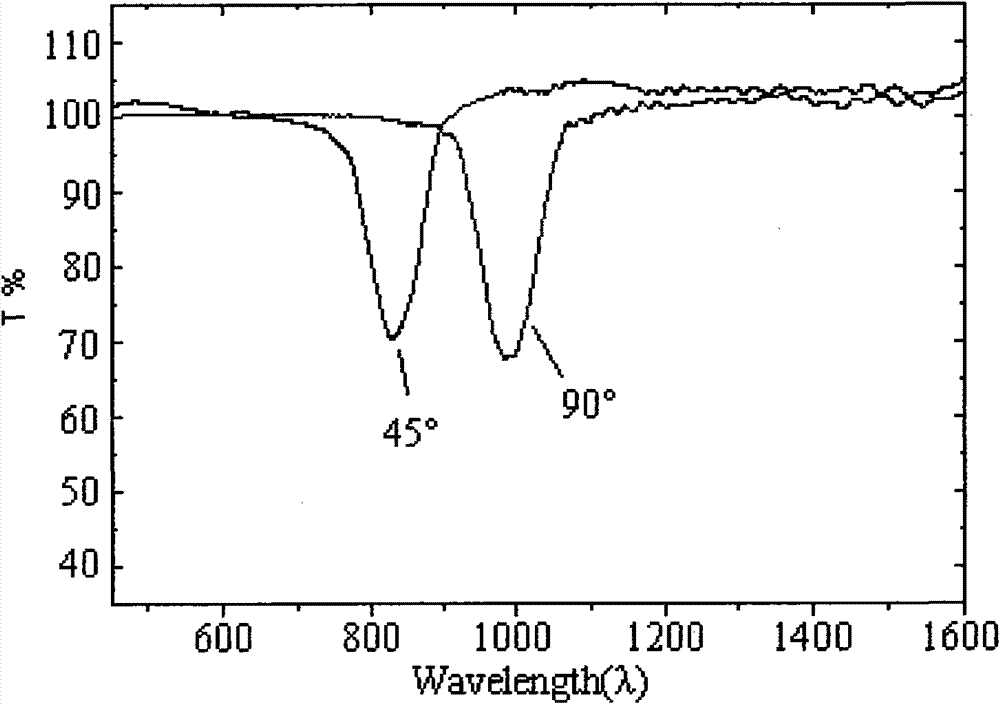

[0067] Three kinds of nematic liquid crystal prepolymer materials used in Example 1, the chiral substance described in US2002076510 (its structural formula is shown in formula III), IRGACURE photoinitiator of Ciba-Geigy company, anisole, cyclopentyl Mix ketones with each other to make a cholesteric liquid crystal solution, change the concentration of the chiral substance so that it is in the lower part of the content range shown in Table 1, and prepare cholesteric liquid crystal solution 1 and cholesteric liquid crystal solution 2 ;

[0068] These two cholesteric liquid crystal solutions 1 and 2 are overprinted on the BOPP substrate (substrate layer) 1 by gravure, dried, and UV cured to form a cholesteric liquid crystal layer 2, forming regions 21 and 22;

[0069] On the other side of the BOPP substrate, hard magnetic ink and soft magnetic ink are overprinted, and after drying, hard magnetic regions (HM) 321 and soft magnetic regions (SM) 322 are formed respectively, forming s...

Embodiment 3

[0074] Three kinds of nematic liquid crystal prepolymer materials in Example 1, chiral substances provided by US6569356 (its structural formula is shown in formula IV, change the concentration of chiral substances in the content range shown in Table 1 for comparison Low part), IRGACURE photoinitiator of Ciba-Geigy company, methyl ethyl ketone, cyclopentanone are mixed mutually, are mixed with cholesteric liquid crystal solution 3 and 4;

[0075] The cholesteric liquid crystal solution 3 and 4 are overprinted on the PET substrate (substrate layer) 1 by gravure, dried, and UV cured to form the cholesteric liquid crystal layer, forming regions 31, 32 and 33, wherein the region 31 is The monolayer region formed by the cholesteric liquid crystal solution 3, the region 33 is the monolayer region formed by the cholesteric liquid crystal solution 4, and the region 32 is an overlapping region formed by two kinds of cholesteric liquid crystal solutions 3 and 4;

[0076] On the same side...

PUM

| Property | Measurement | Unit |

|---|---|---|

| full width at half maximum | aaaaa | aaaaa |

| full width at half maximum | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com