Ganoderma lucidum polysaccharide and preparation method thereof

A technology of Ganoderma lucidum polysaccharide and Ganoderma lucidum, applied in the field of Ganoderma lucidum polysaccharide and its preparation, can solve the problems of many impurities, dark color, etc., and achieve the effects of simple preparation method, improved immune activity, and stimulation of proliferation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Example 1 Preparation of ganoderma lucidum crude polysaccharide by water extraction and ultrafiltration

[0024] Crush the fruiting body of Ganoderma lucidum into small pieces, add water according to the ratio of 1kg fruiting body to 20L water, heat and boil for 2 hours, then filter with a filter cloth (100 mesh), repeat the above steps to extract the filter residue once more and filter, combine the two Extracted filtrate. After the filtrate is concentrated to 10L, the concentrated solution is transferred to UF-3530 ultrafiltration membrane for ultrafiltration (ultrafiltration membrane with a molecular weight cut-off of 10,000 and 500,000 Da is selected), and freeze-dried to finally obtain Ganoderma lucidum crude oil of 10,000-500,000 Da. Dry polysaccharides.

Embodiment 2

[0026] 1. Starting material preparation

[0027] The 1-500,000 Da Ganoderma lucidum crude polysaccharide dry product of Example 1 was formulated into a solution at a mass ratio of 15%, and the precipitated part was removed by centrifugation.

[0028] 2. Anion exchange resin pretreatment

[0029] Rinse with a small flow of 4% HCl until the effluent is acidic, soak for 3 hours, then drain the acid solution, rinse with deionized water until neutral; rinse with a small flow of 4% NaOH until the effluent is alkaline, soak 6h, then drain the lye, rinse with deionized water until neutral.

[0030] 1-500,000 Da ganoderma crude polysaccharide aqueous solution was added to the pretreated anion exchange resin (addition ratio: 40mL ganoderma crude polysaccharide aqueous solution was added to 5mL resin), placed in a 250mL Erlenmeyer flask, shaken in a shaker, 120rpm / min, Decolorize at 30°C and pH 5.0 for 3 hours, then filter with a filter cloth (100 mesh), collect the decolorized Ganoder...

Embodiment 3

[0038] 1. Starting material preparation

[0039] The 1-500,000 Da Ganoderma lucidum crude polysaccharide dry product of Example 1 was formulated into a solution at a mass ratio of 40%, and the precipitated part was removed by centrifugation.

[0040] 2. Anion exchange resin treatment (resin pretreatment method is the same as embodiment 2)

[0041] 1-500,000 Da Ganoderma lucidum crude polysaccharide aqueous solution was added to the pretreated anion exchange resin (addition ratio: 40mL Ganoderma lucidum polysaccharide crude extract was added to 10mL resin; flow rate 3BV / h; room temperature; sample volume 40mL) for decolorization in the column, and collected Decolorized crude polysaccharide aqueous solution.

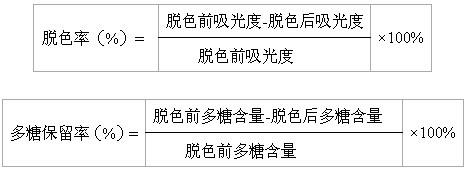

[0042] Measure its polysaccharide content and pigment, compare with embodiment 1, calculate and obtain its decolorization rate 91.06%, polysaccharide retention rate 88.34%.

[0043] 3. Freeze-drying (same as Example 2) to obtain Ganoderma lucidum polysaccharide.

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com