Polyethylene and catalyst composition for its preparation

A technology of polymerization catalyst and catalyst, which is applied in the direction of transportation and packaging, thin material processing, etc., and can solve unsatisfactory problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

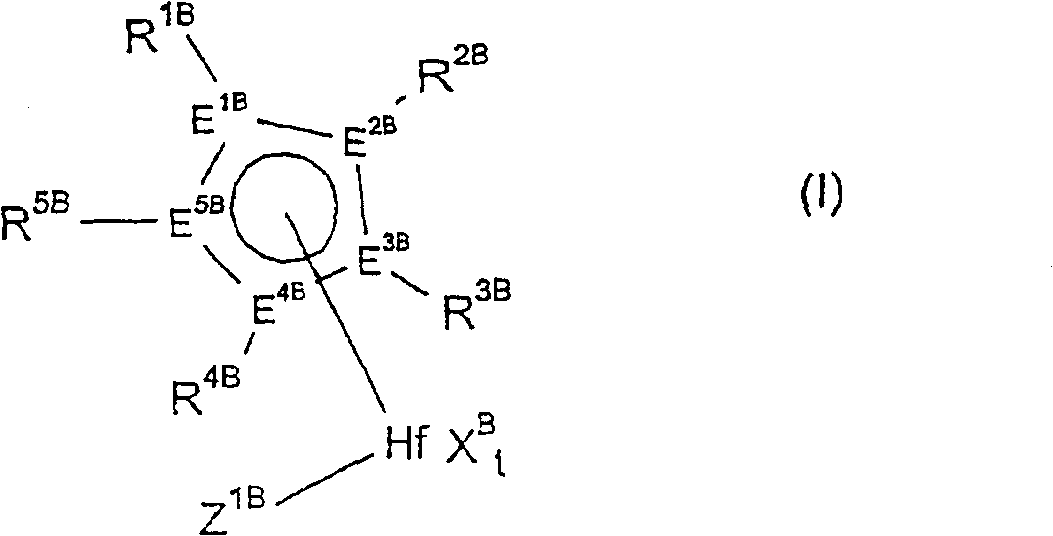

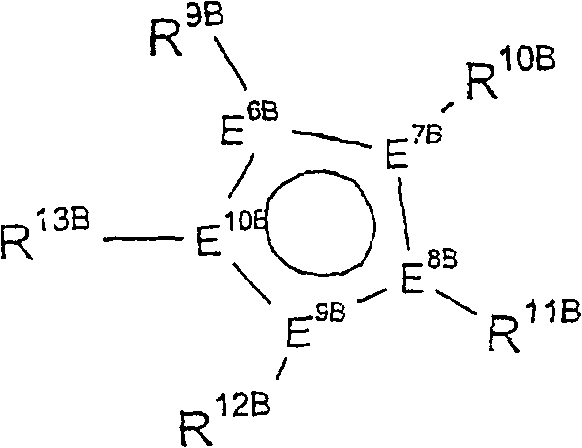

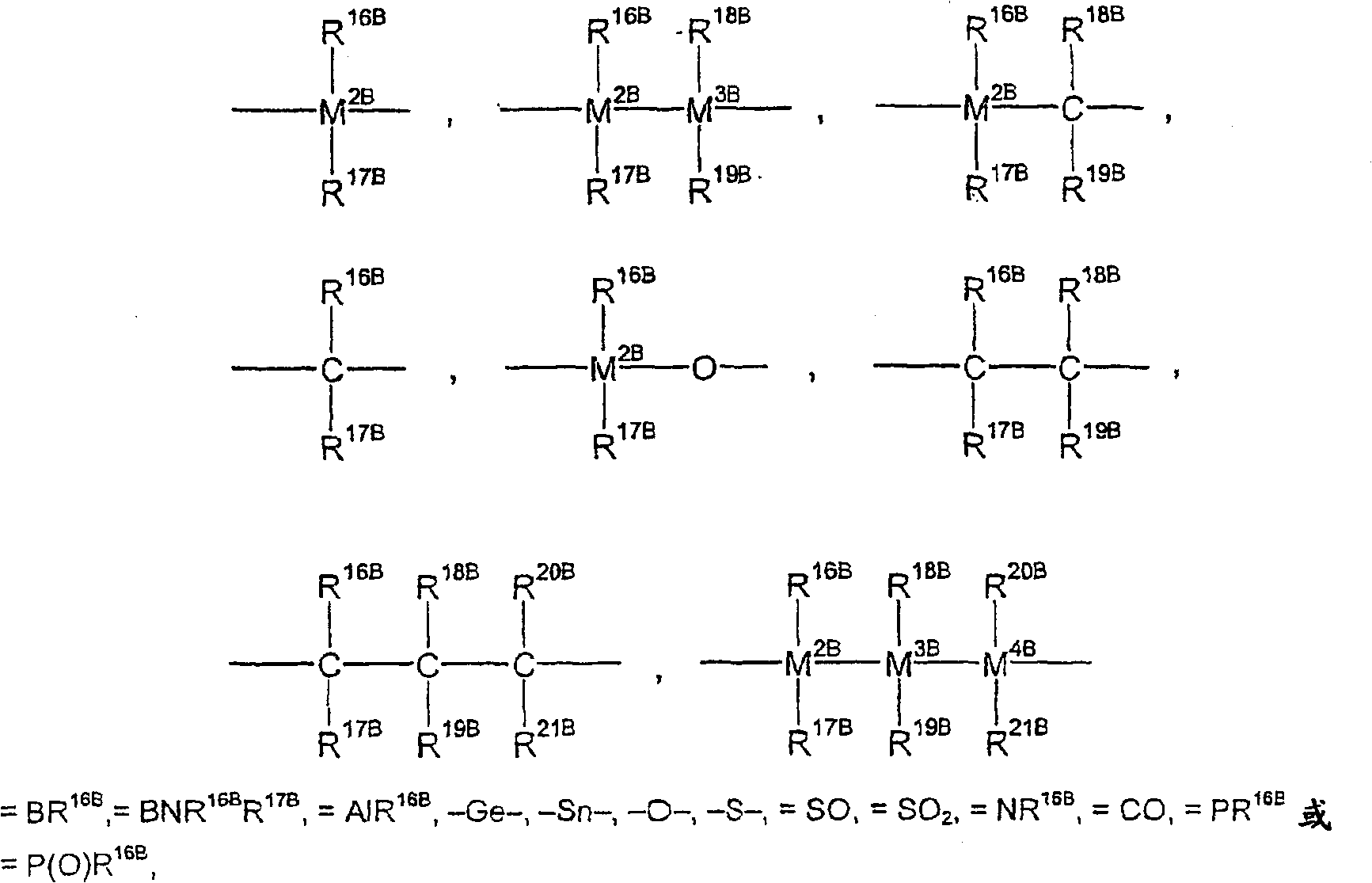

Method used

Image

Examples

preparation example Construction

[0290] Preparation of each component

[0291] 2,6-bis[1-(2-tert-butylphenylimino)ethyl]pyridine was prepared according to the method in Example 6 of WO 98 / 27124 and according to the method in Example 15 of WO 98 / 27124 Methods Preparation of dichloro·2,6-bis[1-(2-tert-butylphenylimino)ethyl]pyridinium iron(II).

[0292] 2,6-bis[1-(2,4,6-trimethylphenylimino)ethyl]pyridine was prepared according to the method in Example 1 of WO 98 / 27124 and reacted with ferric chloride ( II) reaction to give dichloro 2,6-bis[1-(2,4,6-trimethylphenylimino)ethyl]pyridinium iron(II), likewise according to WO 98 / 27124 disclosed method.

[0293] According to the method of Qian et al., Organometallics 2003, 22, 4312-4321, dichloro-2,6-bis[1-(2,4-dichloro-6-methylphenylimino)ethyl]pyridine iron (II). Here, 65.6 g of 2,6-diacetylpyridine (0.4 mol), 170 g of 2,4-dichloro-6-methylaniline (0.483 mol), 32 g of silica gel type 135 and 160 g of molecular sieves (4 Å ) in 1500 ml of toluene was stirred at...

Embodiment 1

[0296] a) Carrier pretreatment

[0297] XPO-2107, a spray-dried silica gel obtained from Grace, was baked at 600°C for 6 hours, and then 252.2 g of the dried silica gel was blended with 164.5 ml of MAO (4.75M in toluene, 0.78 mol). The mixture was stirred for one hour, filtered and the solid was washed with toluene and dried under reduced pressure.

[0298] b) Preparation of mixed catalyst system

[0299] 1.48g (2.45mmol) of dichloro 2,6-bis[1-(2,4-dichloro-6-methylphenylimino)ethyl]pyridinium iron (II), 3.61g (7.34mmol ) of dichlorobis(n-butylcyclopentadienyl)hafnium and 159.6ml of MAO (4.75M in toluene, 0.76mol) was stirred at room temperature for 1 hour, and then added to the 237.1 g of pretreated support material a) were suspended in 800 ml of toluene. The mixture was stirred at room temperature for another 3 hours and the resulting solid was filtered off and washed with toluene. The solid was dried under reduced pressure until free flowing. This gave 256.7 g of catal...

Embodiment 2

[0301] a) Carrier pretreatment

[0302] XPO-2107, spray-dried silica gel obtained from Grace, baked at 600°C for 6 hours.

[0303] b) Preparation of mixed catalyst system

[0304] 5.35g (9.69mmol) of dichloro-2,6-bis[1-(2-tert-butylphenylimino)ethyl]pyridinium iron (II), 7.49g (15.22mmol) of dichloro-bis A mixture of (n-butylcyclopentadienyl)hafnium and 472 ml of MAO (4.75 M in toluene, 2.24 mol) was stirred at room temperature for 30 minutes, and was then added to 276.8 g of in a suspension of the pretreated support material a) ((Fe+Hf):Al=1:90). The solid was dried under reduced pressure until free flowing. This gave 609 g of catalyst, which still contained 31.5% by weight of solvent (based on the total weight and calculated on the basis of complete loading of all components on the support).

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com