Loess relic efflorescence-proof reinforcing agent and preparation and reinforcing method thereof

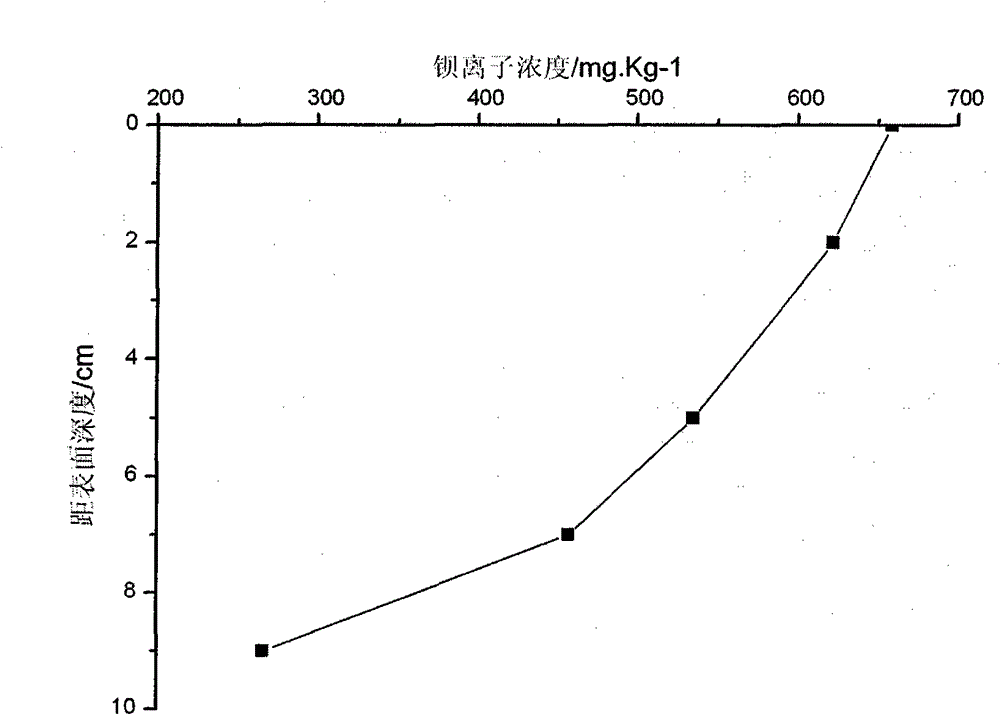

A reinforcing agent and anti-weathering technology, applied in the field of reinforcing materials for protecting loess ruins, can solve the problems of poor air permeability, shallow penetration depth, no concentration gradient and strength gradient, etc., and achieve the effect of promoting polymerization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

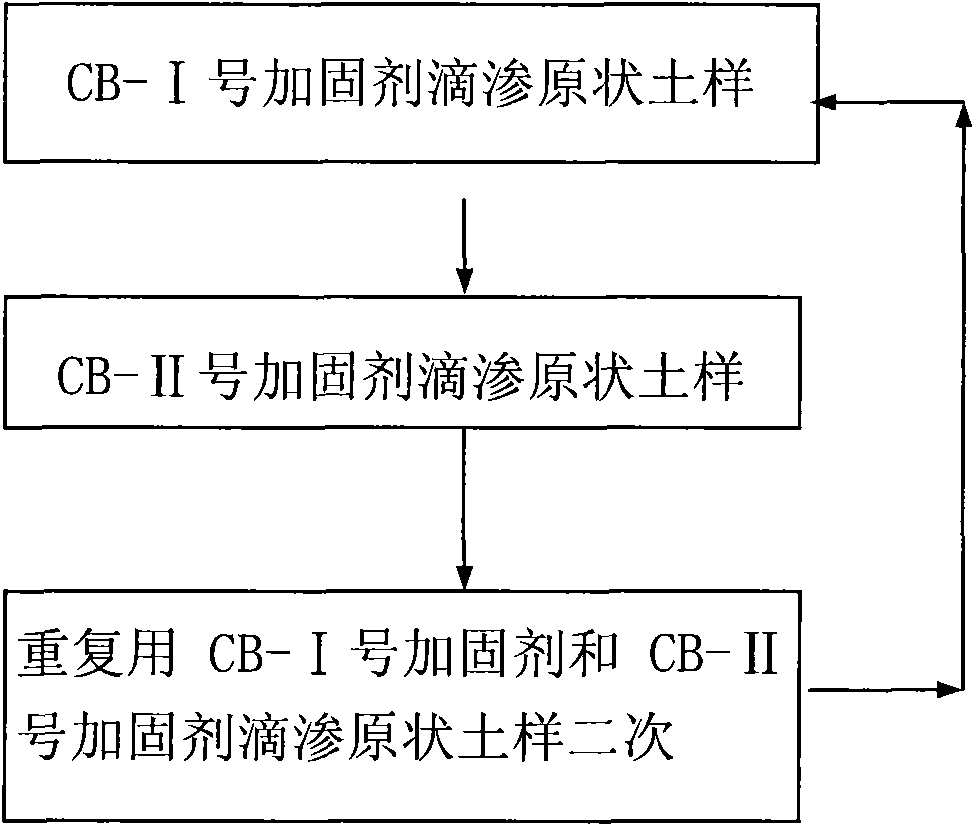

Method used

Image

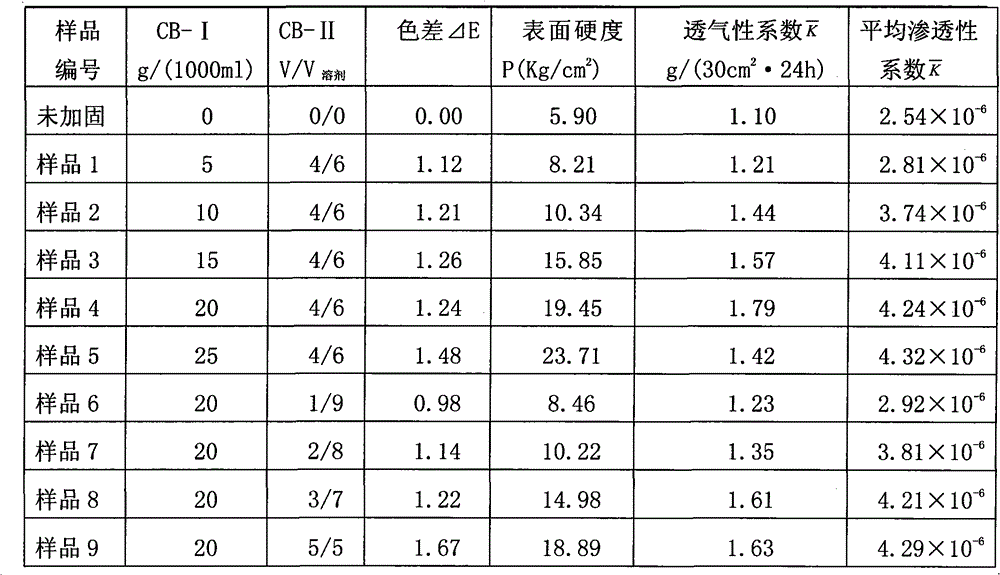

Examples

Embodiment 1

[0063] The present embodiment is a loess site anti-weathering reinforcement and its preparation and reinforcement method. The test site is the non-relic area of the Hanguangmen Site Museum of the Tanghuang City Wall in Xi'an City, Shaanxi Province.

[0064] The loess site weatherproof reinforcement material used in this example contains two types of reinforcements, CB-I and CB-II, of which the reinforcement agent CB-I is a non-ferrous compound prepared by dissolving 5 grams of oxalic acid and 1 milliliter of phosphoric acid in every 1000 milliliters of ethanol. Color clear solution; No. CB-II strengthening agent is a colorless clear solution in which 15 grams of barium hydroxide is dissolved in 2500 ml of methanol. The chemical raw materials are all industrially pure.

[0065] When preparing the above-mentioned loess site anti-weathering reinforcement, the following steps are included:

[0066] Step 1: Preparation of No. CB-I reinforcing agent: Dissolve 5 g of oxalic acid a...

Embodiment 2

[0073] This embodiment is a loess site anti-weathering reinforcement and its preparation and reinforcement method, and the test site is a non-relic area of Xiadian Village, Chang'an County, Shaanxi Province. The moisture content of the test area was 5.12%.

[0074] The weatherproof reinforcement material used in the loess site in this example contains two types of reinforcements, CB-I and CB-II. Among them, No. CB-I reinforcement is made by dissolving 10 grams of oxalic acid and 5 milliliters of phosphoric acid in every 1000 milliliters of ethanol. It is formulated into a colorless and clear solution; CB-II strengthening agent is prepared by dissolving 50 grams of barium hydroxide in 2500 ml of methanol to prepare a colorless and clear solution. The chemical raw materials are all industrially pure.

[0075] When preparing the above-mentioned loess site anti-weathering reinforcement, the following steps are included:

[0076] Step 1: Preparation of No. CB-I reinforcing agen...

Embodiment 3

[0083] The present embodiment is a loess site anti-weathering reinforcement and its preparation and reinforcement method. The test site is a non-relic area in Xiadian Village, Chang'an County, Shaanxi Province, and the moisture content of the test area is 9.83%.

[0084]The loess site anti-weathering reinforcement material used in this example contains two types of reinforcements, CB-I and CB-II. Among them, the reinforcement agent CB-I is made by dissolving 15 grams of oxalic acid and 8 milliliters of phosphoric acid in 1000 milliliters of ethanol. It is formulated into a colorless and clear solution; CB-II strengthening agent is prepared by dissolving 90 grams of barium hydroxide in 2500 ml of methanol to prepare a colorless and clear solution. The chemical raw materials are all industrially pure.

[0085] When preparing the above-mentioned loess site anti-weathering reinforcement, the following steps are included:

[0086] Step 1: Preparation of No. CB-I Reinforcing Agent:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| penetration depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com