Electrothermal organic electrode slurry for heater

An organic electrode, electric heating technology, applied in the direction of heating element materials, etc., can solve the problems of easy detachment of solder joints, easy surface oxidation, short service life, etc., to achieve good printability and wettability, good dispersibility and common. Solubility, long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

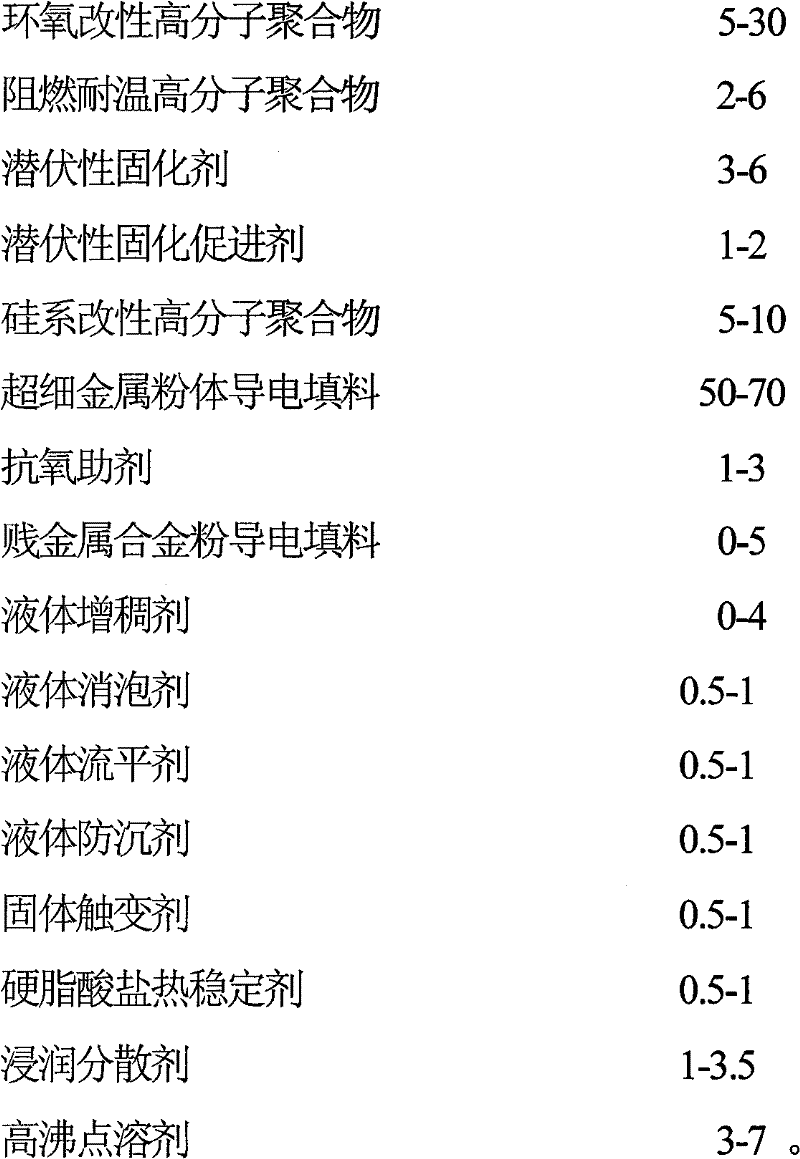

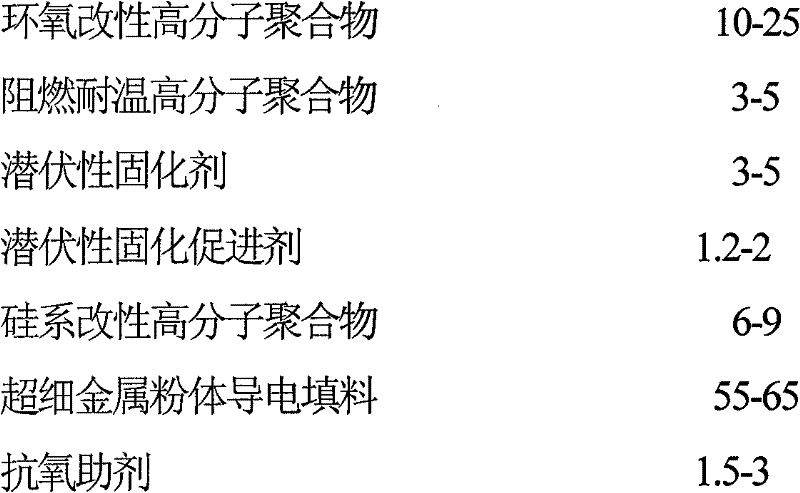

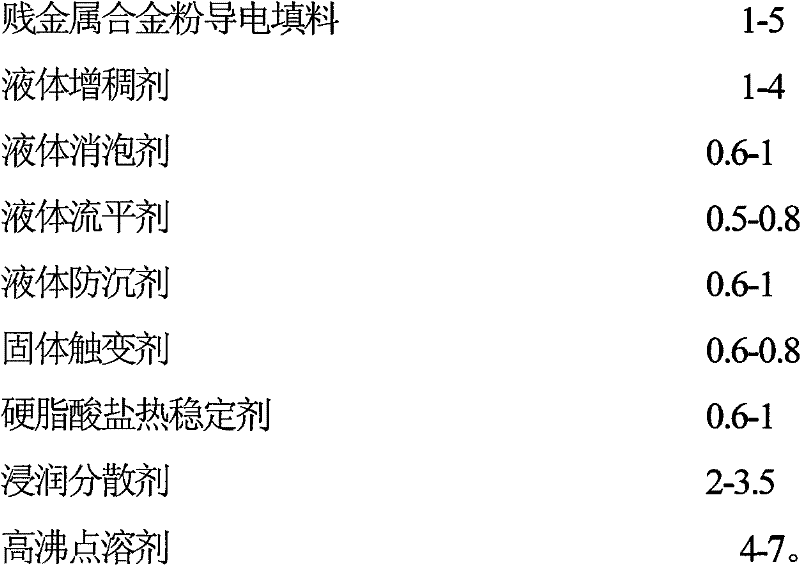

[0035] The invention provides an electrothermal high-temperature-resistant organic electrode slurry especially suitable for plate heaters, which is mainly composed of an organic binder phase, a functional phase, a functional auxiliary phase and other functional phases. The formulation mechanism is explained as follows:

[0036] The organic binder phase is the main body of the system formula, which is mainly a blend of epoxy modified high molecular polymer, boron flame retardant and temperature resistant high molecular polymer and silicon modified high polymer organic body. It mainly provides the slurry system with excellent adhesion to the printing substrate, and excellent geometric deformation consistency with the printing substrate; provides a stable geometric structure and surface hardness for the cured film, so that the cured film has excellent temperature resistance, and Good flame retardancy and thermal oxygen aging resistance; provide suitable viscosity, leveling perfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com