Method for reclaiming gold and silver in tailings after roasting-cyaniding of gold concentrate

A recovery method and technology for gold concentrate, applied in the field of hydrometallurgy, can solve the problem of insufficient recovery of tailings, and achieve the effects of easy popularization and application, significant benefits, and huge economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] The tailings after the roasting and cyanidation of gold concentrate contain 2g / t of gold, 45g / t of silver, and 40% of total iron. The moisture of the tailings after drying is 5%. The addition amount is 80% of tailings quality. Restore in a tunnel kiln at 1100°C for 15 hours, then cut off the air to cool and discharge the material, separate and remove the coal powder impurities, and then crush the sponge iron; dilute the crushed metal iron powder with industrial concentrated sulfuric acid and dissolve it in acid to obtain For iron solution, the acid dissolution conditions are as follows: temperature 80°C, final acid concentration 15g / L, ferrous iron concentration 89g / L, acid dissolution 3h. Gold and silver precious metals in acid slag were extracted by carbon slurry cyanidation method. The ferrous solution is evaporated and crystallized to obtain the ferrous product.

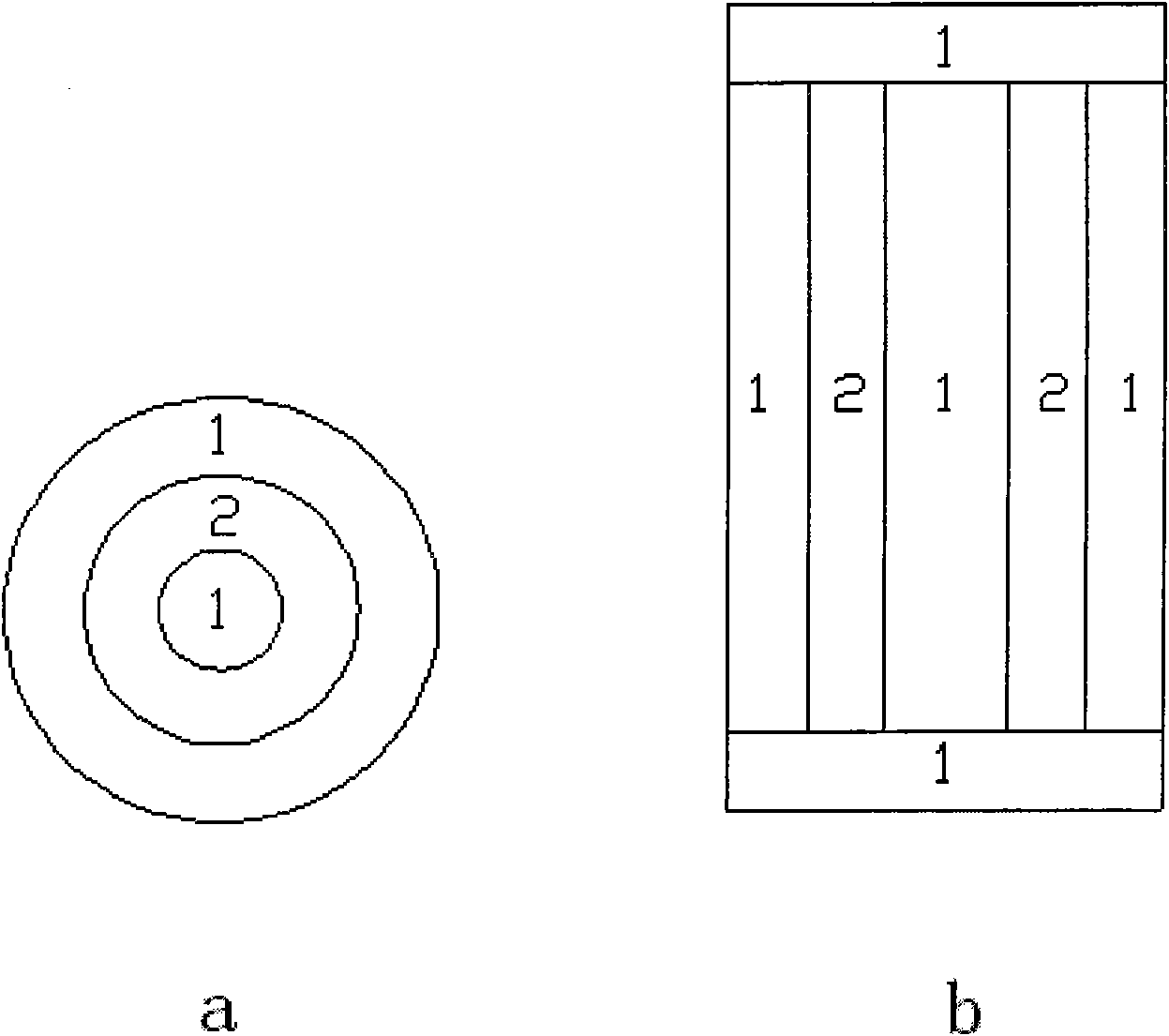

[0021] With canned ring packing, see figure 1 The innermost and outer rings of the concentric rings ...

Embodiment 2

[0024] The tailings after the roasting and cyanidation of gold concentrates contain 1.8g / t of gold, 40g / t of silver, and 30% of iron. The moisture of the tailings after drying is 2%. The addition amount is 70% of tailings quality. Restore in a tunnel kiln at 1000°C for 10 hours, then cut off the air to cool and discharge the material, separate and remove the coal powder impurities, and then crush the sponge iron; dilute the crushed metal iron powder with industrial concentrated sulfuric acid and dissolve it in acid to obtain For iron solution, the acid dissolution conditions are as follows: temperature 80°C, final acid concentration 15g / L, ferrous concentration 85g / L, acid dissolution 2.5h. Gold and silver precious metals in acid slag were extracted by carbon slurry cyanidation method. The ferrous solution is evaporated and crystallized to obtain the ferrous product.

[0025] With canned ring packing, see figure 1 The innermost and outer rings of the concentric rings and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com