Recovery method of anode materials for lithium-ion batteries

A lithium-ion battery and negative electrode material technology, which is applied in the field of lithium-ion battery negative electrode material recovery, can solve the problems of long high-temperature treatment time (1-24 hours, complicated processing procedures, unfavorable production efficiency, etc., and achieve the elimination of the process of ball milling and crushing , simple process and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

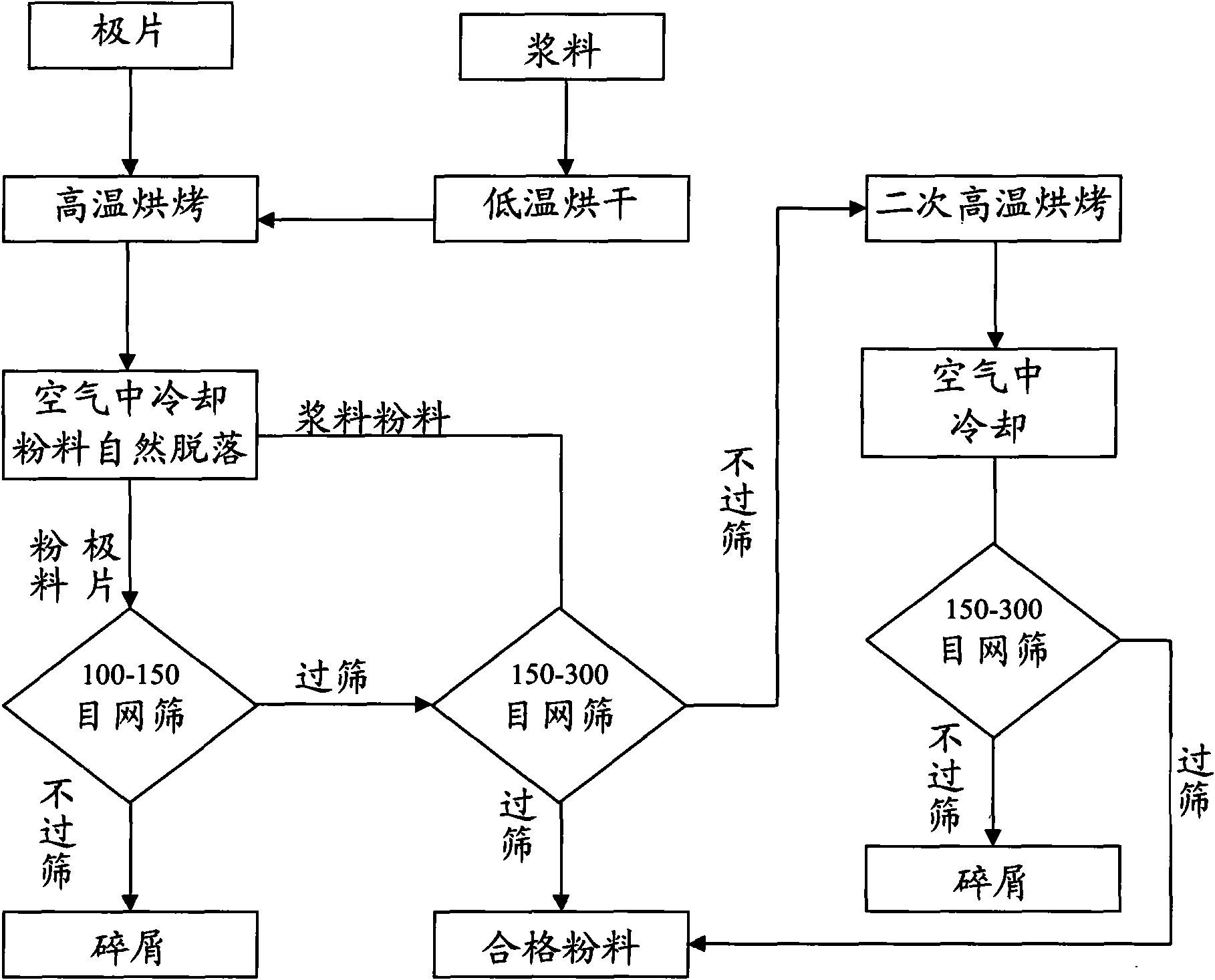

[0033] The first embodiment: a pole piece recycling method.

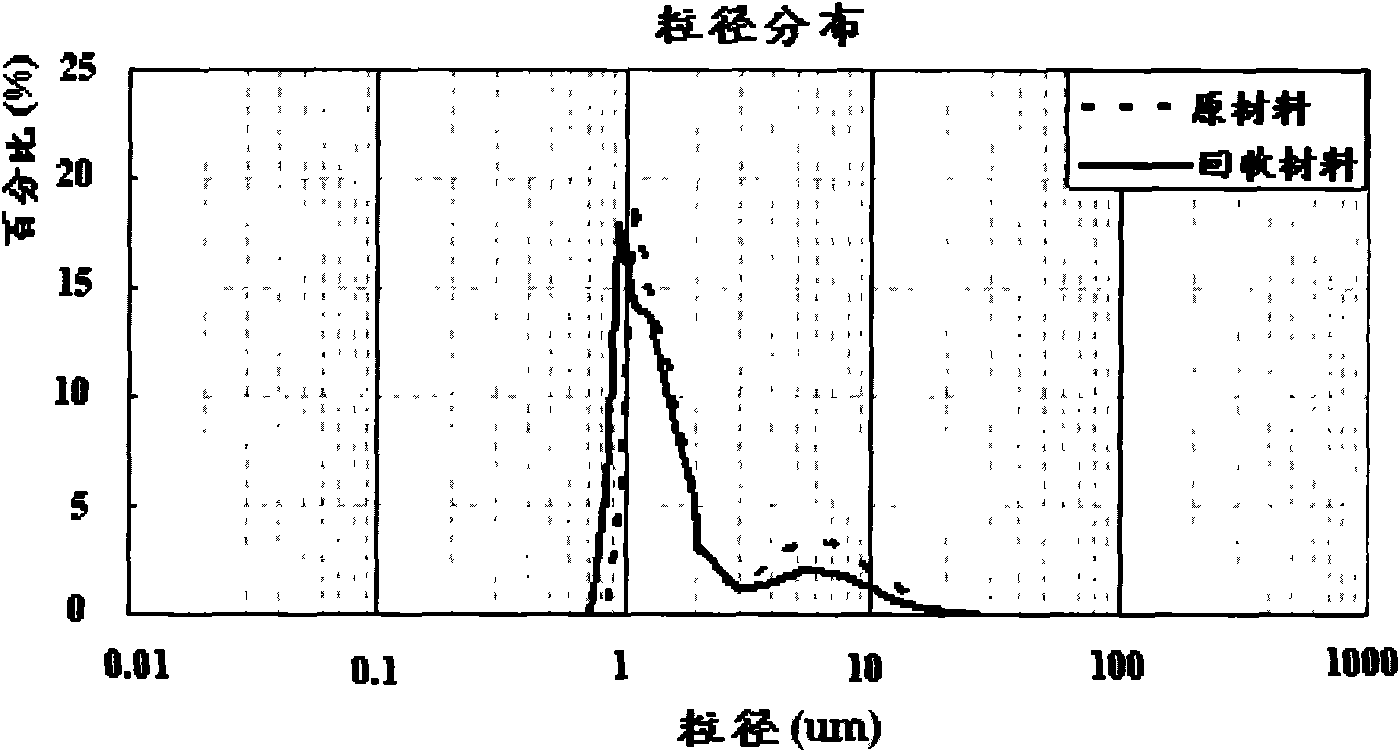

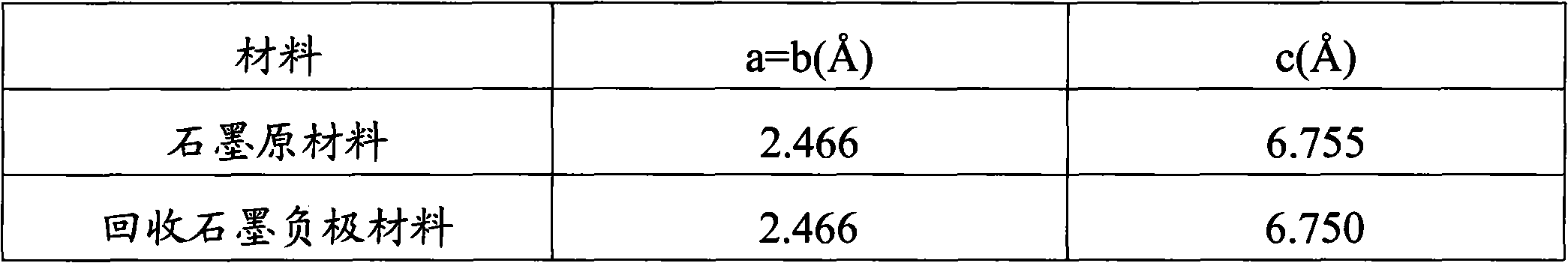

[0034] Firstly, stack 1 kg of graphite negative pole pieces to be recovered neatly in a metal container in a dense manner and cover the surface with a layer of metal foil, and put it into a high-temperature furnace that has been heated to 400-600°C, preferably 500°C , take it out after baking at constant temperature for 10 minutes, and cool it to normal temperature in the air. At this time, the negative electrode material has completely fallen off from the current collector; Turn on the vibrating sieve machine, and select 100 mesh for the vibrating screen. After this process, copper foil scraps are obtained on the upper part of the screen, and graphite particles are obtained on the lower part; after that, the obtained graphite particles are passed through a 200 mesh screen to obtain qualified graphite particles in the lower part of the screen; finally, the Put the graphite particles with larger particle size in the...

no. 2 approach

[0035] The second embodiment: a slurry recovery method.

[0036] First, put 1 kg of graphite negative electrode slurry to be recovered into a high-temperature blast drying oven for low-temperature drying at a drying temperature of 100-200°C. After 12 hours, a larger graphite block is obtained; then, the obtained graphite block is placed in a Put it into a high-temperature furnace with a temperature of 400-600°C, preferably 500°C, bake at a constant temperature for 10 minutes, take it out, and cool it to room temperature in the air; after that, pass the obtained graphite particles through a 200-mesh sieve, Graphite particles with qualified particle size are obtained; finally, put the graphite particles with larger particle size on the upper part into a high-temperature furnace at 400-600°C, preferably 500°C, for secondary baking, cool to room temperature in air, and pass through the oven again. 200-mesh sieve, a small part of the graphite particles that cannot be sieved can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com