Graded-distribution ferroelectric phase change type lead magnesio-niobate-lead titanate ceramic material

A lead magnesium niobate, gradient distribution technology, applied in the field of ferroelectric materials, can solve the problems of high cost of rare earth raw materials, complex preparation process, easy moisture absorption, etc., and achieve easy storage and use, simple preparation process, and convenient raw material processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

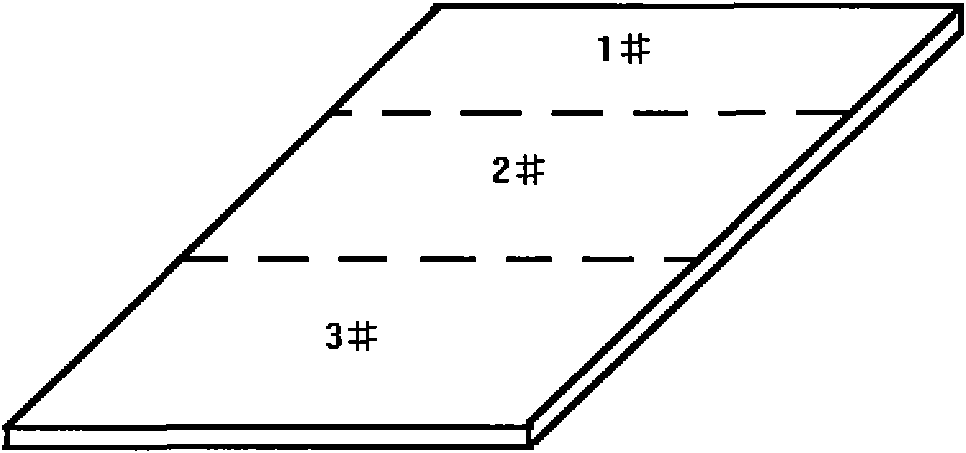

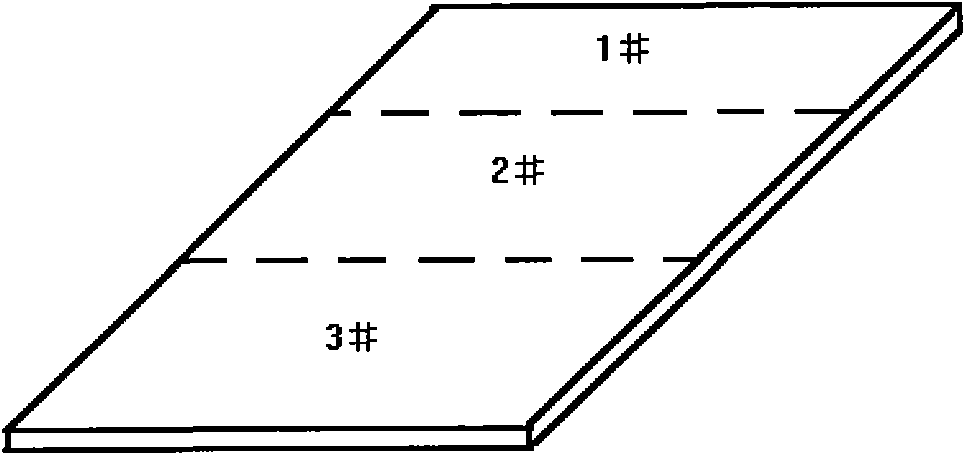

[0039] Parallel gradient lead magnesium niobate-lead titanate ferroelectric phase change ceramic material.

[0040] The formulations of the components of the lead magnesium niobate-lead titanate binary system high pyroelectric ceramic material are: (1-x)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 +x PbTiO 3 ; x=0.32(1#), 0.33(2#), 0.34(3#), the process for preparing this multi-component nonlinear pyroelectric ceramic material is:

[0041] (1) Preparation of MgNb 2 o 6 , with basic MgCO 3 and Nb 2 o 5 reaction, where MgCO 3 and Nb 2 o 5 The feed ratio (molar ratio) is 1:1, the reaction temperature is 950-1020° C., and the reaction time is 2-6 hours.

[0042] (2) Preparation of lead magnesium niobate-lead titanate powder, that is, adding PbO and TiO in proportion to the chemical formula 2 and other raw materials with the above MgNb 2o 6 Medium reaction, the reaction conditions are: first react at 680-720°C for 1-3 hours, and then react at 820-860°C for 1-3 hours.

[0043] (3) First ins...

Embodiment 2

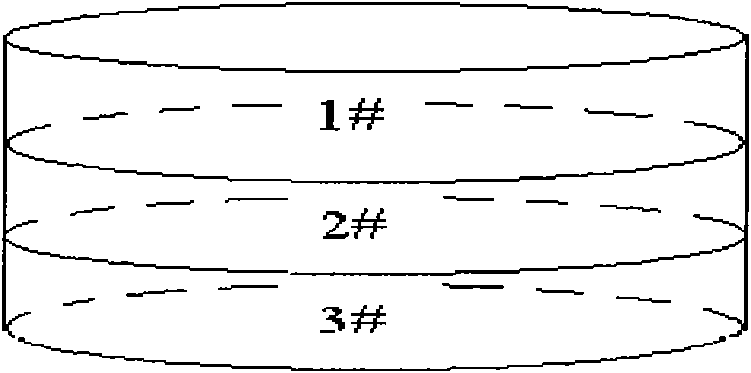

[0048] Laminated gradient lead magnesium niobate-lead titanate ferroelectric phase change ceramic material.

[0049] The composition formula of lead magnesium niobate-lead titanate binary system high pyroelectric ceramic material is:

[0050] (1-x)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 +x PbTiO 3 ; x=0.31(1#), 0.33(2#), 0.35(3#), the process for preparing this type of gradient ceramic material is:

[0051] (1) Preparation of MgNb 2 o 6 , that is, in the basic form of MgCO 3 and Nb 2 o 5 reaction, where MgCO 3 and Nb 2 o 5 The feed ratio (molar ratio) is 1:1, the reaction temperature is 950-1020° C., and the reaction time is 2-6 hours.

[0052] (2) Preparation of lead magnesium niobate-lead titanate powder, that is, adding PbO and TiO in proportion to the chemical formula 2 , MnO 2 and other raw materials with the above MgNb 2 o 6 Medium reaction, the reaction conditions are: first react at 680-720°C for 1-3 hours, and then react at 820-860°C for 1-3 hours.

[0053] (3) Fill th...

Embodiment 3

[0058] The composition formula of the doped lead magnesium niobate-lead titanate binary system ceramic material is: (1-x)Pb(Mg 1 / 3 Nb 2 / 3 )O 3 +x PbTiO 3 , x=0.33, wherein the doping element is Al (in Al 2 o 3 Form), the doping amount is 0.5wt%Al respectively 2 o 3 (1#), 0.8wt% Al 2 o 3 (2#), 1.0wt% Al 2 o 3 (3#), the process for preparing this gradient ferroelectric phase change ceramic material is:

[0059] (1) According to the preparation process of lead magnesium niobate-lead titanate powder described in Example 1, each component powder was prepared.

[0060] (2) Place the spacer in the mold first, fill the above-mentioned lead magnesium niobate-lead titanate component powder into the corresponding area, then remove the spacer, and press molding (see figure 1 shown).

[0061] (3) Sintering is carried out according to the conventional ceramic material sintering process, the sintering temperature is 1270-1300° C., and the sintering time is 1-3 hours.

[0062] (4...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap