Etchant composition for and etching method of materials containing copper

A technology of etchant and composition, which is applied in the etchant composition for copper-containing materials and the field of etching of copper-containing materials, and can solve the problems of inability to obtain etching performance, poor shape of circuit patterns, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 and comparative example 1

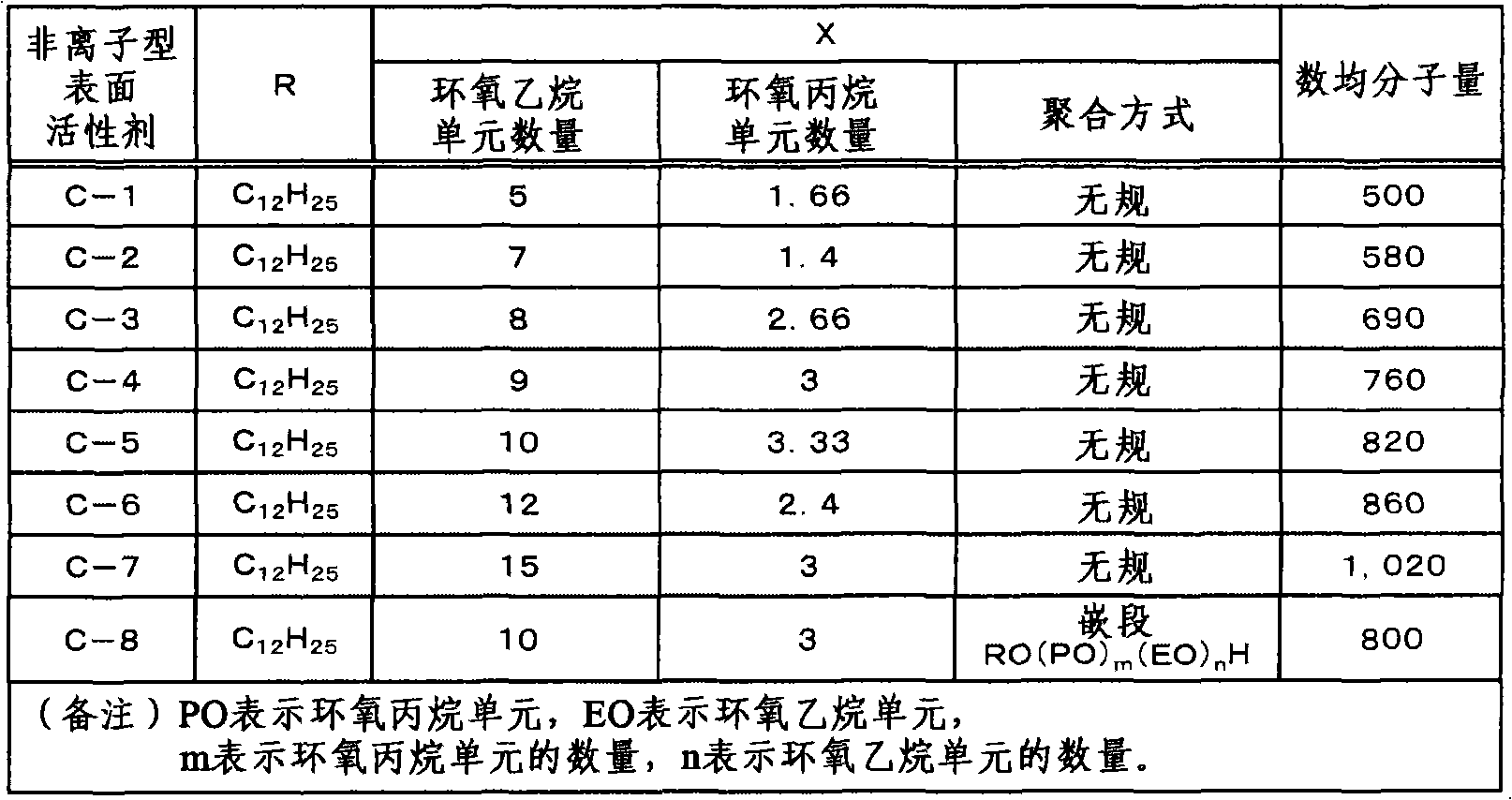

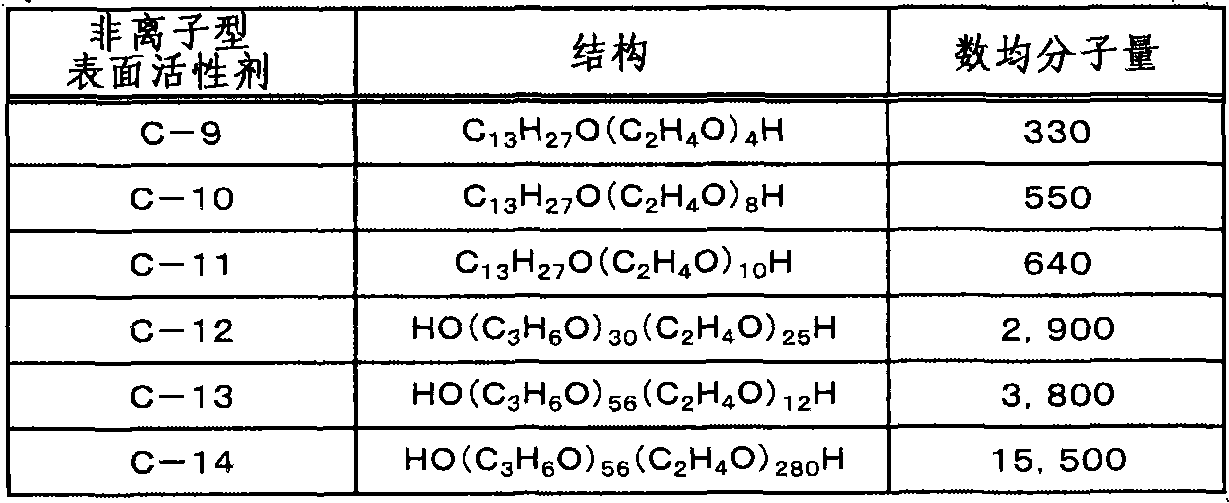

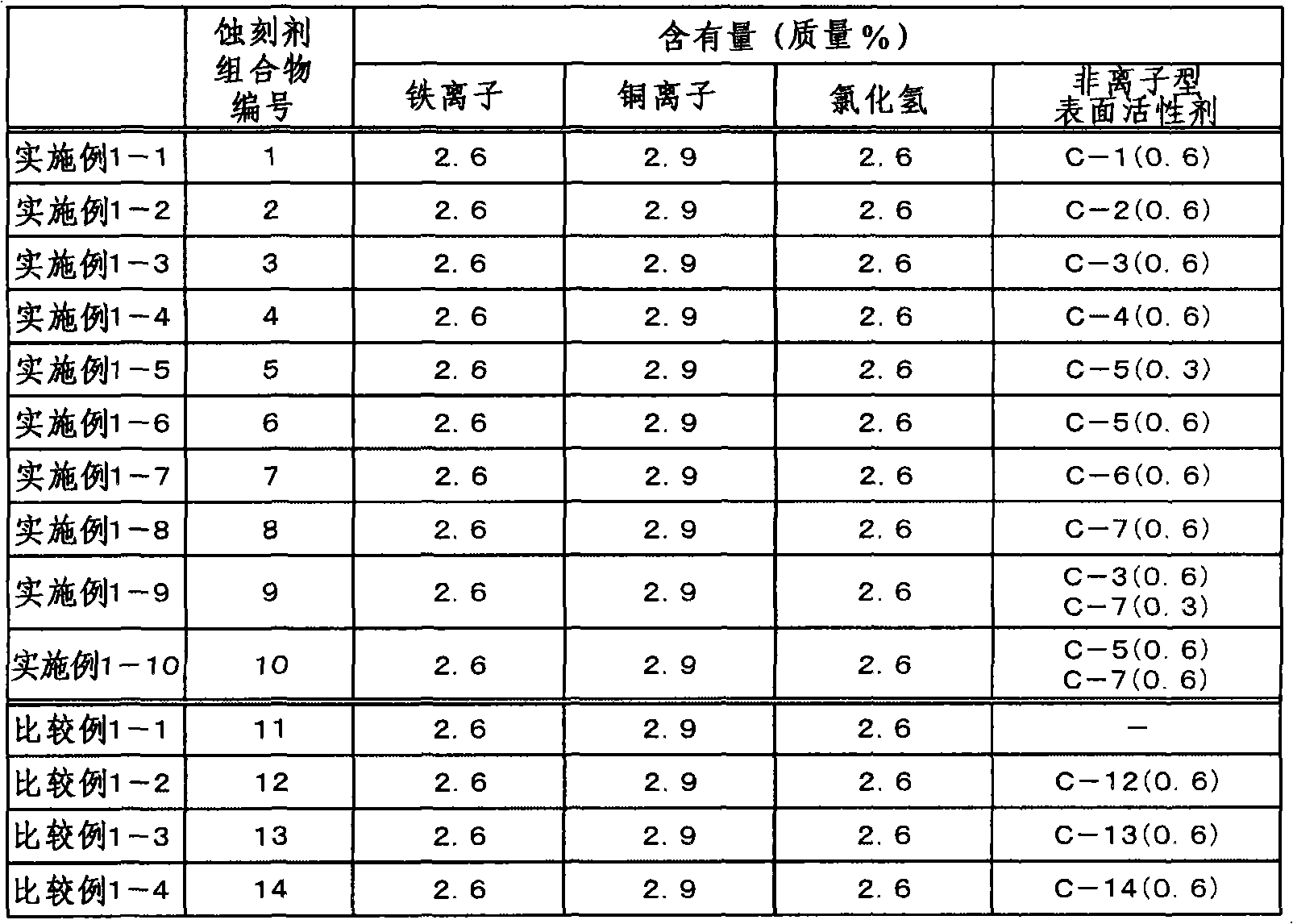

[0068] The nonionic surfactant shown in Table 1 and Table 2, ferric chloride (iron ion), hydrogen chloride, copper (copper ion) and water were mixed according to the composition in Table 3 to obtain an etchant composition. In addition, the remainder of the content in Table 3 is water.

[0069] table 3

[0070]

Embodiment 2 and comparative example 2

[0072] The etchant obtained in the above-mentioned Examples and Comparative Examples was used for a test substrate in which a dry film resist patterned with a line width of 100 μm and a predetermined line spacing (etching space) was formed on a resin substrate having a copper foil with a thickness of 20 μm. composition, spray etching the test substrate under specified conditions. Thereafter, the dry film resist was removed by immersing in a 5% by mass sodium hydroxide aqueous solution (50° C.) for 1 minute. The shape of the obtained copper circuit was evaluated as follows.

[0073] (1) Wiring upper width (top width)

[0074] The cross section (observation section) was measured with an optical microscope. The unit is μm.

[0075] (2) Wiring lower part width (bottom width)

[0076] The cross section (observation section) was measured with an optical microscope. The unit is μm.

[0077] (3) Difference between bottom width and top width

[0078] Calculate it using the follo...

Embodiment 3 and comparative example 3

[0088] The nonionic surfactants shown in Table 1 and Table 2, ferric chloride, hydrogen chloride, copper, and water were mixed according to the composition in Table 6 to obtain an etchant composition. In addition, the remainder of the content in Table 6 is water.

[0089] Table 6

[0090]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com