Composite porous electrode for sulfuric acid system and preparation method thereof

A porous electrode and sulfuric acid system technology, applied in the field of electrochemistry, can solve problems such as the difficulty of direct compounding of substrates and porous layers, complex casting devices and casting processes, shortening the life of composite porous electrodes, etc., to achieve easy control of the seepage process and high yield , the effect of a reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

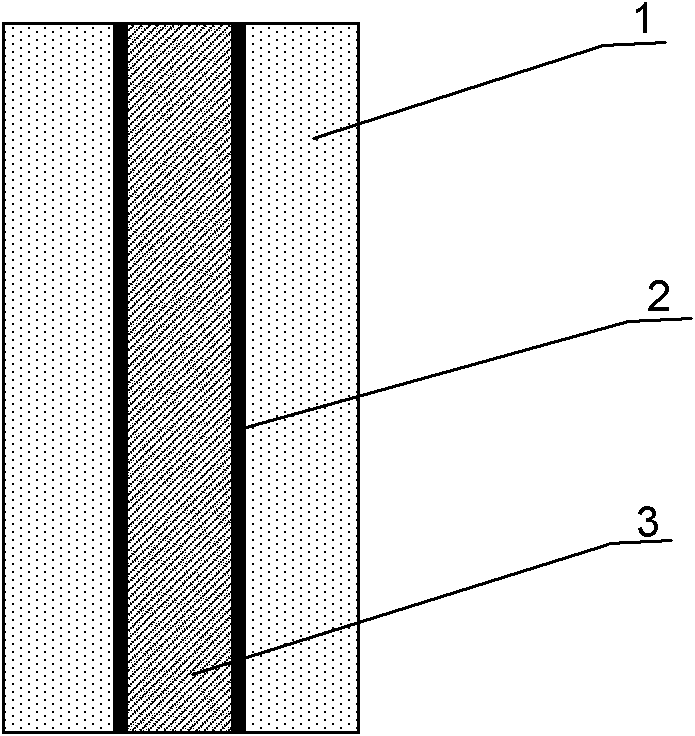

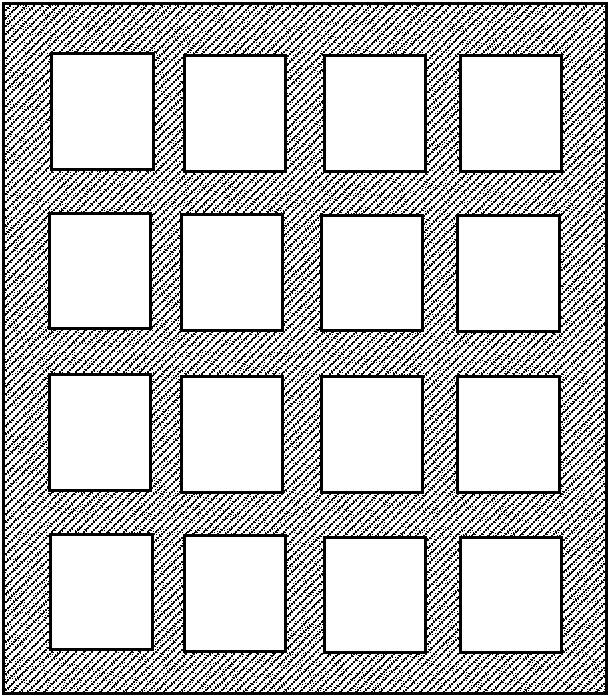

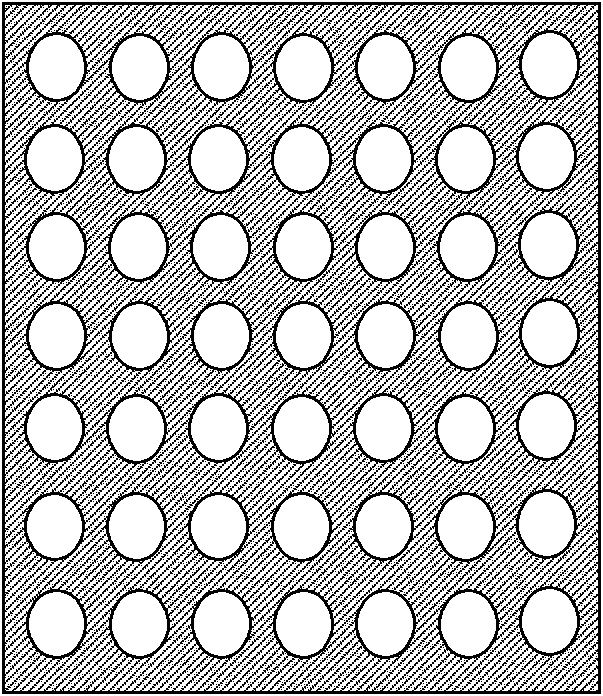

[0041] Immerse an 8mm thick Pb-Ca(0.09wt.%)-Sn(0.98wt.%)-Al(0.011wt.%) plate in a Pb-Ag(0.8wt.%) melt at 330°C for 5s to obtain 0.05mm thick Pb-Ag transition layer, and then the reinforced metal substrate coated with Pb-Ag transition layer on the surface and K with a particle size of 0.8mm-1.0mm 2 SO 4 The filler particles are made into prefabricated blocks. Put the prefabricated block into the infiltration chamber and heat it to 250°C; heat the Pb-Ag(0.8wt.%)-Bi(0.3wt.%) alloy to 400°C to melt, and apply the filling pressure to drive the molten Pb-Ag ( 0.8wt.%)-Bi(0.3wt.%) alloy enters the percolation chamber at a speed of 0.05m / s, is filled and cooled naturally, and then the filler particles are removed by washing with hot water at 50°C to obtain Pb-Ca (0.09wt. %)-Sn(0.98wt.%)-Al(0.011wt.%) / Pb-Ag(0.8wt.%) / Pb-Ag(0.8wt.%)-Bi(0.3wt.%) composite porous electrode.

Embodiment 2

[0043] Place 304 stainless steel plate in PbCl 2 (70wt.%)-CaCl 2 (14wt.%)-NaCl (15wt.%) plating system Pb coating in molten salt, described 304 stainless steel plate thickness is 0.5mm, and described molten salt temperature is 480 ℃; Then immediately in 400 ℃ of Pb-Nd (0.1 wt.%) alloy melt for 20s to obtain a Pb-Nd transition layer with a thickness of 0.1mm. K with a particle size of 1.0mm-1.2mm 2 SO 4 The filler particles and the stainless steel plate coated with Pb-Nd transition layer are put into the infiltration chamber together and preheated to 200°C; the Pb-Ag (0.8wt.%) alloy is heated to 400°C to melt. Apply the filling pressure, drive the molten Pb-Ag (0.8wt.%) alloy to enter the infiltration chamber from the bottom of the infiltration chamber along the anti-gravity direction at a speed of 0.2m / s, and cool naturally after filling, and then remove the filler particles with clean water to obtain Steel / Pb-Nd(0.1wt.%) / Pb-Ag(0.8wt.%) composite porous electrode.

Embodiment 3

[0045] A 1mm thick Al-Si (1wt.%) alloy radial frame was exposed to PbCl at 500°C 2 (80wt.%)-CaCl 2 (9wt.%)-NaCl(10wt.%)-SnCl 2 (1wt.%) Pb-Sn alloy was plated in molten salt, and immersed in molten Pb-Sn (20wt.%) alloy at 400°C for 5s to obtain a 0.15mm thick Pb-Sn alloy transition layer. Al-Si (1wt.%) alloy radial frame coated with a Pb-Sn alloy transition layer on the surface and CaSO with a particle size of 1.6mm to 2.0mm 4 The filler particles are made into prefabricated blocks, and the prefabricated blocks are placed in the percolation chamber, and the filler particles together with the reinforced substrate are preheated to 300°C; Pb-Ag(0.3wt.%)-Ca(0.03wt.%)-Sr(0.03wt. %) alloy is heated to 500°C to melt, and the filling pressure is applied to drive the molten Pb-Ag(0.3wt.%)-Ca(0.03wt.%)-Sr(0.03wt.%) alloy from The bottom of the seepage chamber enters the seepage chamber along the anti-gravity direction, it is filled and cooled, and the NH 4 HCO 3 Aqueous solution rem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com