Method for preparing ordered mesoporous carbon material by direct self-assembly

An ordered mesoporous and self-assembly technology, applied in the field of material preparation, can solve the problems of a large number of solvents, pollute the environment, waste raw materials, etc., and achieve the effect of low cost, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Preparation of organic polymer phenolic resin: Melt 92.0 g of phenol in a water bath at 49 °C, add 19.5 g of 20% NaOH aqueous solution by mass percentage, stir for 10 minutes, add 162.8 g of formaldehyde solution (37 wt %), at 70 Reflux for 1 hour at °C and cool to room temperature. Adjust the pH to about 7 with 2.0 M hydrochloric acid solution, place the reaction system in a water bath at 50 °C for vacuum distillation, remove the water, and obtain 71.5 g of organic polymer phenolic resin (molecular weight 200-500). Dissolve 71.5 g of organic polymers in about 20 g of absolute ethanol, centrifuge to remove NaCl crystals, place the reaction system in a water bath at 48 °C and distill off ethanol under reduced pressure to obtain a light brown liquid phenolic resin for later use.

Embodiment 2

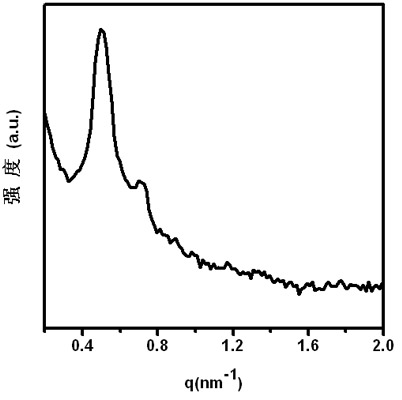

[0039] Preparation of organic-organic mixture: 10.0 g of nonionic surfactant polyethylene oxide-polypropylene oxide-polyethylene oxide triblock copolymer (Pluronic F127) was added to 10.0 g of phenolic resin, at 35 Mechanical stirring (300 rpm) in a water bath at °C for 3 hours gave a yellow transparent viscous mixture. The SAXS spectrum proves that the obtained mixture has a certain ordered mesoscopic structure, indicating that non-ionic surfactants and organic polymer phenolic resins can self-assemble in this extremely concentrated organic-organic system. See SAXS spectrum figure 1 .

Embodiment 3

[0041] Preparation of cured polymer composites obtained by using plastic as a mold: 15.0 g of nonionic surfactant Pluronic F127 was added to 15.0 g of phenolic resin, and mechanically stirred (rotating at 300 rpm) in a water bath at 35 °C for 3 hours to obtain a yellow transparent Viscous mixture. The mixture was transferred into a plastic mold with a thickness of 0.9 cm and directly placed in an oven at 100 °C for 24 hours, cooled to room temperature, and the mold was removed to obtain a solidified polymer composite, as shown in the optical photo. optical photo see figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com