Method for preparing nano microcapsule water-based color paste

A technology of nano-microcapsules and water-based color paste, which is applied in the direction of dyeing method, pigment paste, application, etc., to achieve the effect of enhancing thermal stability and light resistance/weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0041] 1) Preparation of nano-microcapsule core by miniemulsion polymerization

[0042] 0.65g sodium lauryl sulfate and 0.1g sodium bicarbonate were dissolved in a beaker containing 100g deionized water as the water phase; 16g styrene, 2g methyl Add methyl acrylate and 1.5g divinylbenzene to another beaker, then add 1.3g C.I. solvent red 146, 0.16g droplet nucleation accelerator and 0.08g reactive light stabilizer GW-628, after completely dissolving As the oil phase; pour the water phase into the oil phase, mechanically stir at 1200 rpm at room temperature for 20 minutes, then place it in an ultrasonic homogenizer under an ice-water bath for fine emulsification, and the ultrasonic power is 450 watts , after 15 minutes of fine emulsification, the fine emulsion was obtained; the prepared fine emulsion was put into a 250ml four-necked flask connected with stirring, thermometer, condenser and nitrogen pipe, and the temperature was raised to 60°C after first passing through nitroge...

specific Embodiment 2

[0046] 1) Preparation of nano-microcapsule core by miniemulsion polymerization

[0047] 0.5g sodium lauryl sulfate and 0.1g sodium bicarbonate were dissolved in a beaker containing 100g deionized water as the water phase; 16g styrene, 2g methyl Add methyl acrylate and 1.2g 1,4-butanediol diacrylate to another beaker, then add 1.0g C.I. solvent red H, 0.16g droplet nucleation accelerator and 0.08g reactive light stabilizer HA -R100, completely dissolved and used as the oil phase; pour the water phase into the oil phase, mechanically stir at room temperature at a speed of 1200 rpm for 20 minutes, and then place it in an ultrasonic homogenizer under an ice-water bath for fine emulsification. The ultrasonic power is 450 watts, and the fine emulsion is obtained after 12 minutes of fine emulsification; the prepared fine emulsion is put into a 250ml four-necked flask connected with stirring, thermometer, condenser and nitrogen pipe, and nitrogen gas is introduced for 15 minutes to re...

specific Embodiment 3

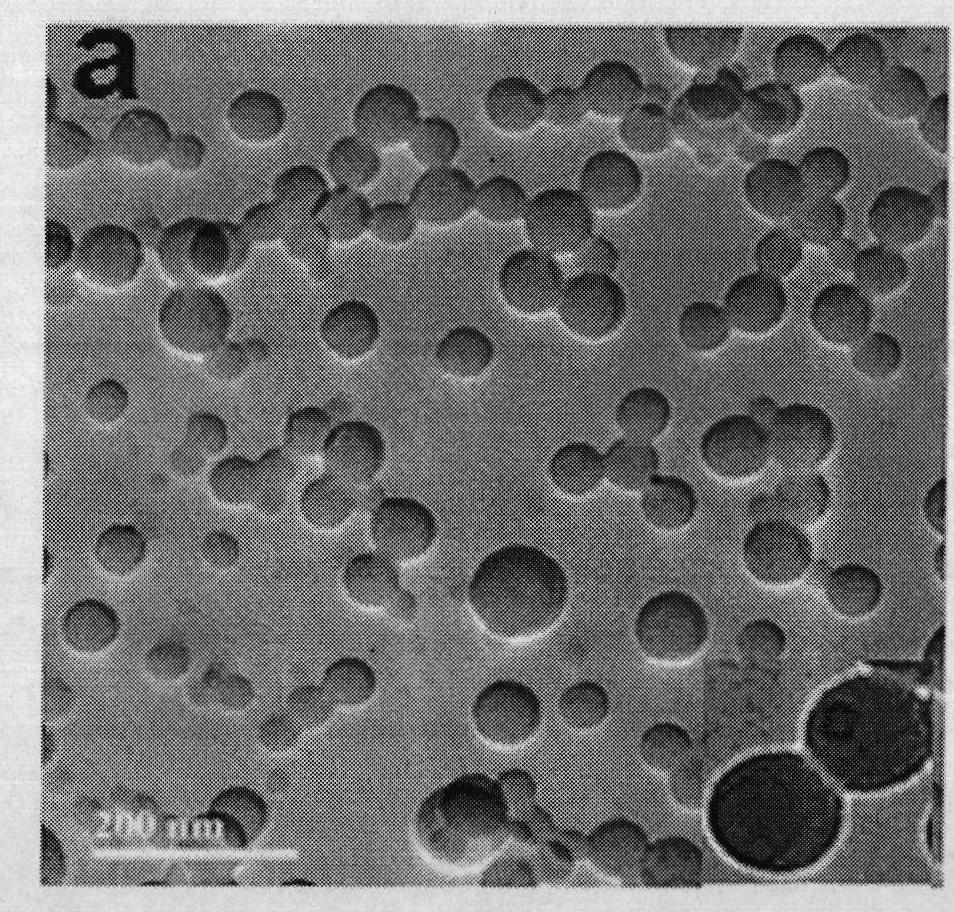

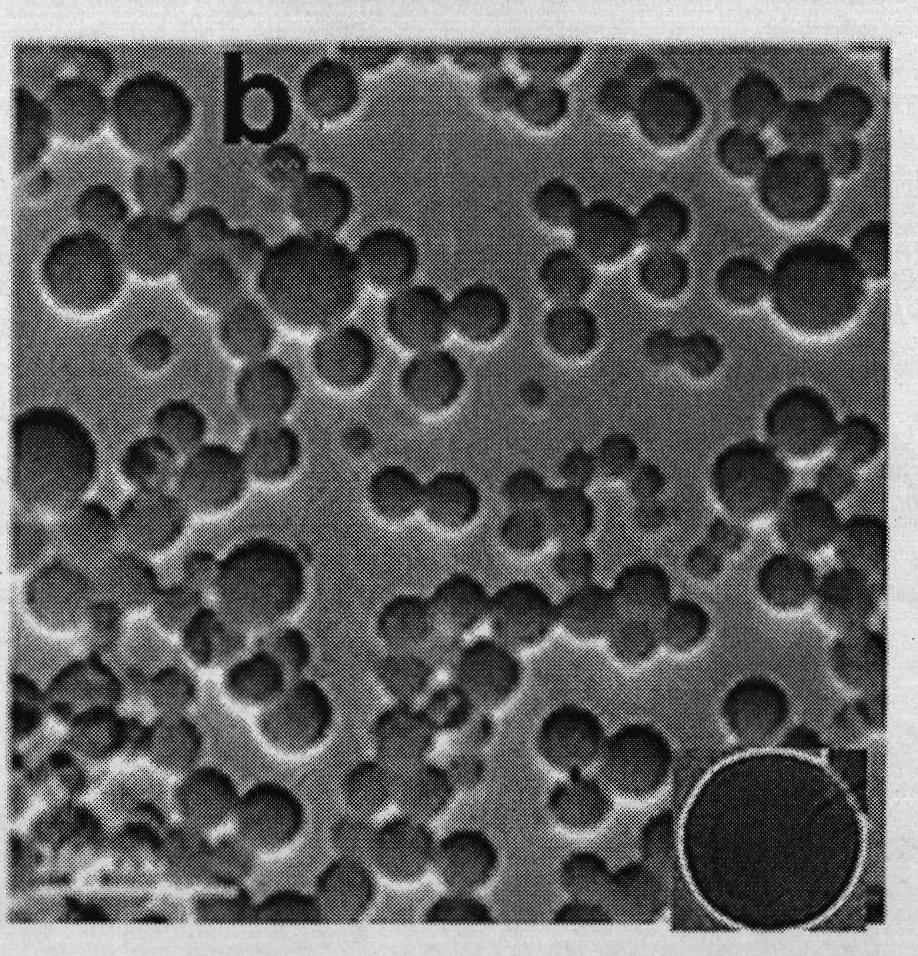

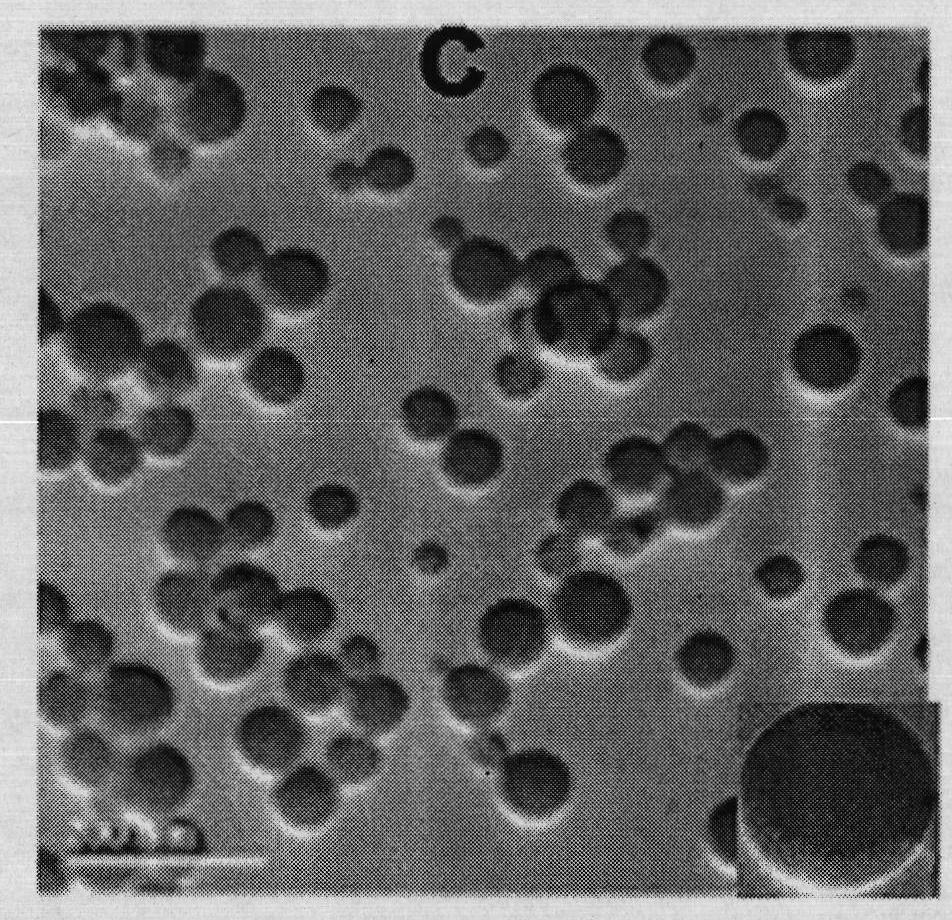

[0050] The characteristics of this embodiment are: according to embodiment 1, the dye in the miniemulsion polymerization reaction is changed to 1.5g C.I. Solvent Yellow 93, and all the other formulas and processes are the same. The finally obtained yellow nano-microcapsule-type water-based color paste exhibits excellent water-based dispersion properties (see Table 1), and the corresponding dyes have greatly improved light fastness / weather properties (see Table 2); from figure 2 In the TEM image, it can be found that the pigment paste particles have built a relatively complete microcapsule structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| surface tension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com