Preparation method of modified azo yellow pigment derivative dispersant as well as prepared derivative dispersant and application thereof

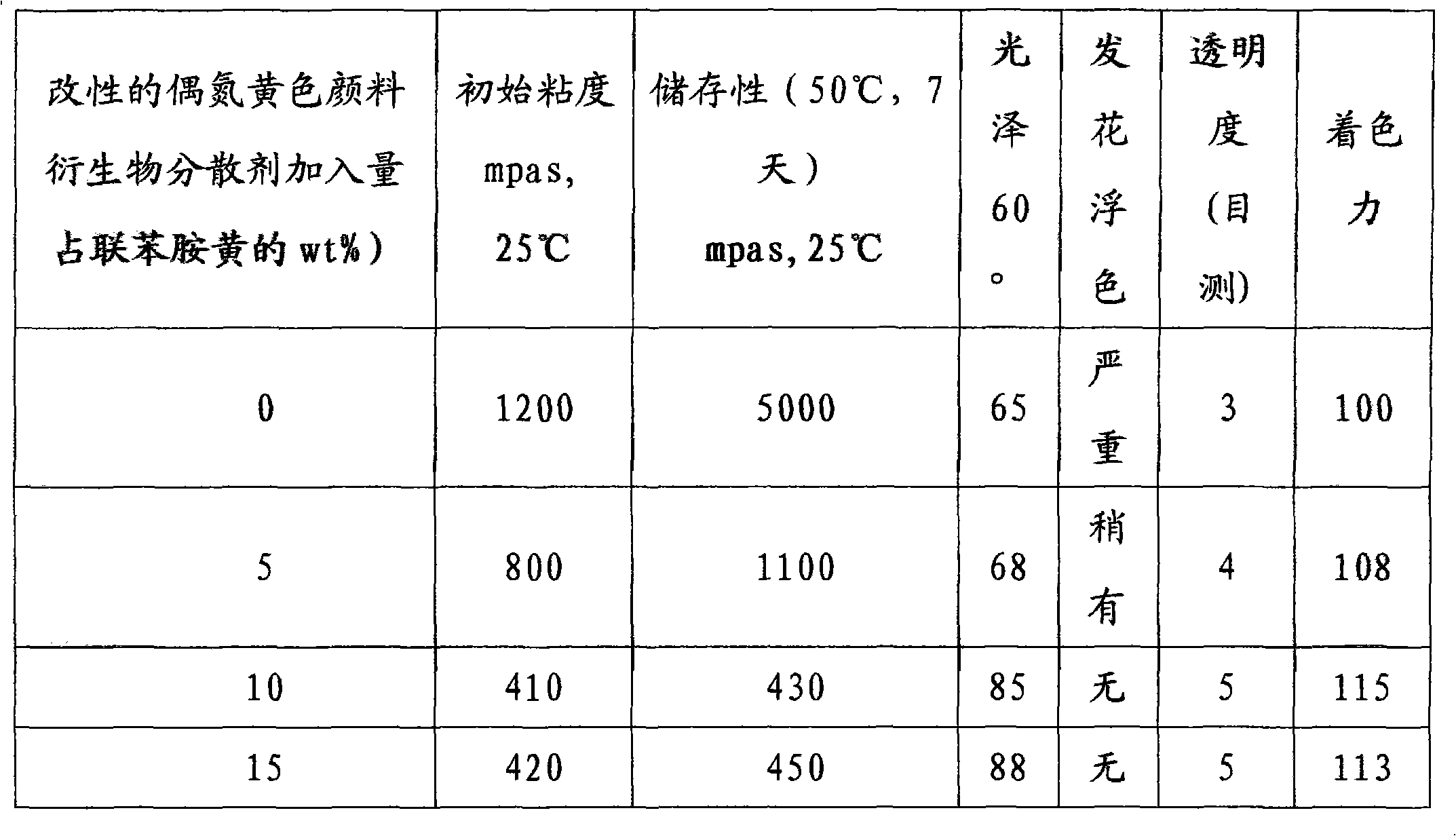

A technology for yellow pigments and derivatives, applied in the field of pigments, can solve problems such as poor storage stability, poor compatibility, and whitening, and achieve the effects of reducing whitening and blooming, increasing storage stability, and reducing viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

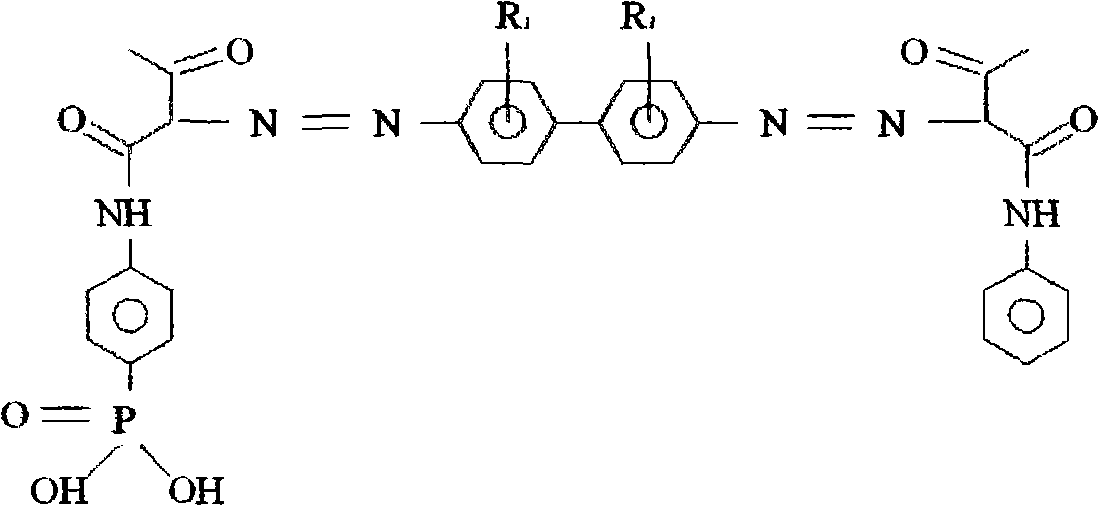

[0029] (1) Synthesis of 4-acetoacetamidophenylphosphonate: Dissolve 1mol of 4-aminophenylphosphonic acid in 1000mL of water, add 1mol of solid sodium hydroxide, and add 1mol of diketene dropwise at a temperature of 5°C. , under normal pressure, stirred and reacted for 30 minutes, concentrated and dried to obtain 4-acetoacetamidophenylphosphonic acid sodium salt.

[0030] (2) Preparation of diazo solution: in 150mL water, add 30wt% hydrochloric acid solution (Hcl0.5mol in hydrochloric acid), start stirring, add 3,3-dichlorobenzidine 0.1mol, stir for 30 minutes, at a temperature of At 0°C, quickly add 8 wt% solution made of 0.205 mol of sodium nitrite, carry out diazotization reaction for 1 hour, starch potassium iodide test paper turns blue, and filter to obtain diazonium solution.

[0031] (3) Preparation of coupling solution: in 650mL water, add 30wt% sodium hydroxide solution (sodium hydroxide 0.45mol in sodium hydroxide), stir, add acetoacetanilide 0.105mol, and step (1) ob...

Embodiment 2

[0035] (1) Synthesis of 4-acetoacetamidophenylphosphonate: Dissolve 2mol 4-aminophenylphosphonic acid in 2000mL water, add 2mol solid potassium hydroxide, when the temperature is 2°C, add 2.1mol diketene dropwise, at 105 ℃, under normal pressure, stirred and reacted for 40 minutes, concentrated and dried to obtain 4-acetoacetamidophenylphosphonic acid potassium salt.

[0036] (2) Preparation of diazo solution: in 300mL water, add 30wt% hydrochloric acid solution (Hcl0.95mol in hydrochloric acid), start stirring, add 3,3-dichlorobenzidine 0.2mol, stir for 20 minutes, at a temperature of At -2°C, quickly add a 10wt% solution made of 0.4 mol potassium nitrite, carry out diazotization reaction for 1 hour, starch potassium iodide test paper turns blue, and filter to obtain diazonium solution.

[0037] (3) Preparation of coupling solution: in 1300mL water, add 30wt% potassium hydroxide solution (0.9mol of potassium hydroxide in potassium hydroxide solution), stir, add acetoacetanili...

Embodiment 3

[0041] (1) Synthesis of 4-acetoacetamidophenylphosphonate: Dissolve 1mol of 4-aminophenylphosphonic acid in 1000mL of water, add 1mol of sodium hydroxide, and add 1.1mol of diketene dropwise at a temperature of 0°C. , under normal pressure, stirred and reacted for 40 minutes, concentrated and dried to obtain 4-acetoacetamidophenylphosphate sodium salt.

[0042] (2) Preparation of diazo solution: in 150mL water, add 30wt% hydrochloric acid solution (Hcl0.45mol in hydrochloric acid), start stirring, add 3,3-dichlorobenzidine 0.1mol, stir for 25 minutes, at a temperature of At -5°C, quickly add a 10wt% solution made of 0.21 mol of sodium nitrite, carry out diazotization reaction for 1 hour, starch potassium iodide test paper turns blue, and filter to obtain diazonium solution.

[0043](3) Preparation of coupling liquid: in 650mL water, add 30wt% sodium hydroxide solution (sodium hydroxide 0.42mol in sodium hydroxide), start stirring, add acetoacetanilide 0.11mol, and step (1) obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com