Process for growing lead tungstate crystal by vertical gradient solidification method

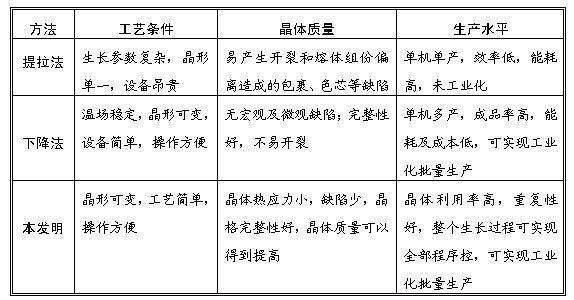

A vertical gradient solidification, lead tungstate technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of volatile tungsten oxide, low crystal yield, high production cost, and achieve good quality uniformity. , the crystal quality is improved, the lattice integrity is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] According to the stoichiometric composition of the polycrystalline ingot, it is PbO with a purity of 99.999% and WO powder with a purity of 99.999%. Burn the mixed powder and direction cylindrical seed crystal, put them into a cylindrical platinum crucible, melt the raw material and the top of the seed crystal at 1130°C, the temperature gradient near the seed crystal and the melt is about 15°C / cm, The inside of the body is about 8°C / cm; the cooling rate is 2°C / h, the moving speed is 400μm / h, and cylindrical crystals grow.

Embodiment 2

[0020] The initial raw material composition is: PbO with a purity of 99.999% and WO powder with a purity of 99.999% according to the stoichiometric composition of the polycrystalline ingot, and the ratio of the substances is 1:1; 3 hours; put the pre-fired mixed powder and direction cylindrical seed crystal into a rectangular cylindrical platinum crucible, melt the raw material and the top of the seed crystal at 1150 ° C, and the temperature gradient near the seed crystal and the melt About 15°C / cm, inside the melt about 8°C / cm. The cooling rate was 2°C / h, the moving speed was 400 μm / h, and rectangular columnar crystals were grown.

Embodiment 3

[0022] The initial raw material composition is: PbO with a purity of 99.999% and WO powder with a purity of 99.999% according to the stoichiometric composition of the polycrystalline ingot, and the ratio of the substances is 1:1. After mixing evenly, pre-fire the material at 750°C for 2.5 hours, put the pre-fired mixed powder and the hexagonal seed crystal in the direction into a platinum crucible with a wall thickness of 0.3mm, and heat it at 1200°C Melt the top of the raw material and the seed crystal, the temperature gradient is about 15°C / cm near the seed crystal and the melt, and about 8°C / cm inside the melt. The cooling rate is 2° C. / h, the moving speed is 400 μm / h, and a complete crystal of PWO is grown.

[0023] The directions of the seed crystals are not limited to the directions disclosed in the above specific embodiments, and may be along any other directions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com