Cylindrical brushing machine

A brushing machine and cylinder technology, applied in application, seed and rhizome treatment, agriculture, etc., can solve the problems of short lint corrosion, flue gas emission, low technical level, etc., to prevent excessive heating, easy machine load, guarantee The effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below in conjunction with the accompanying drawings, and this manufacturing method is very clear to those skilled in the art.

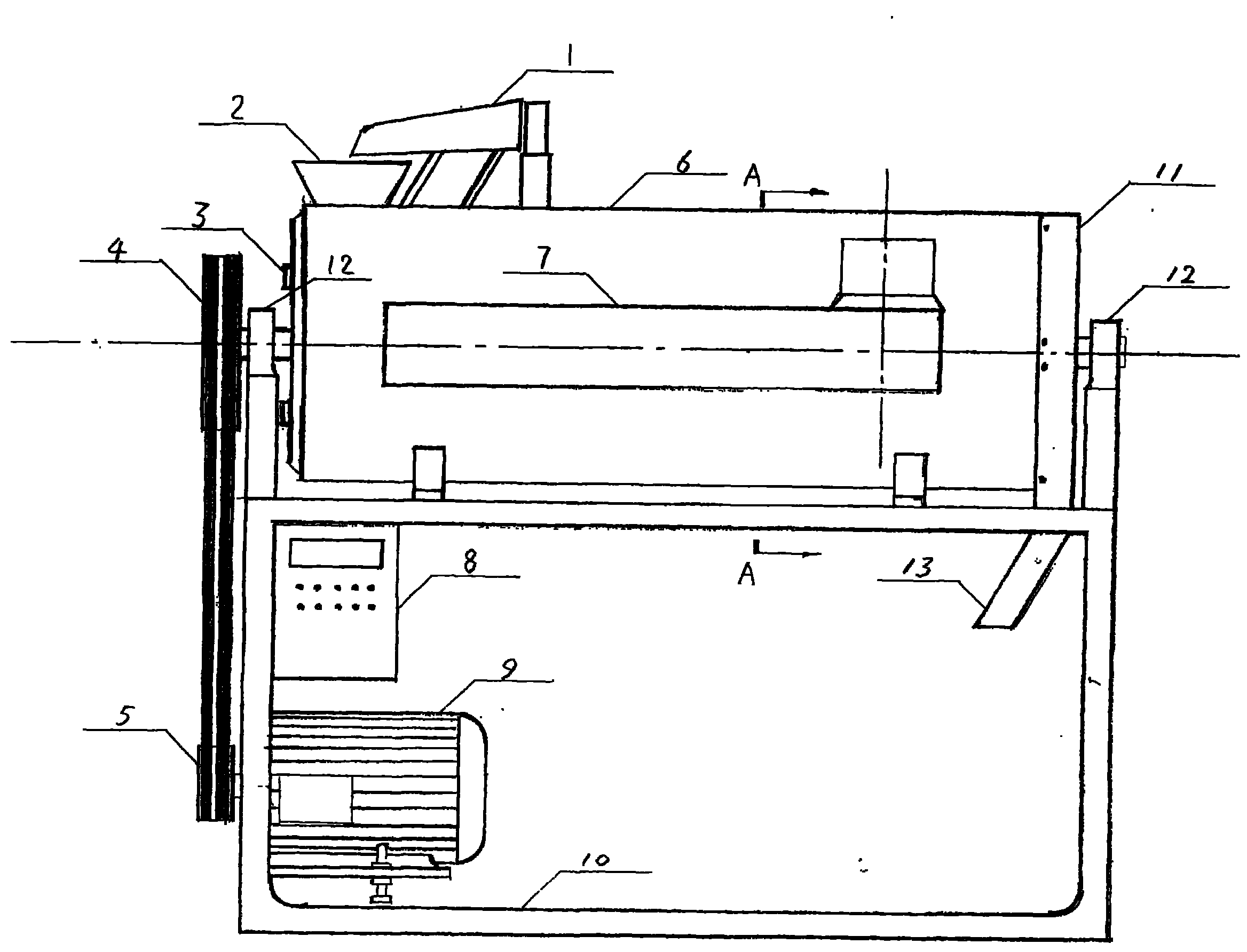

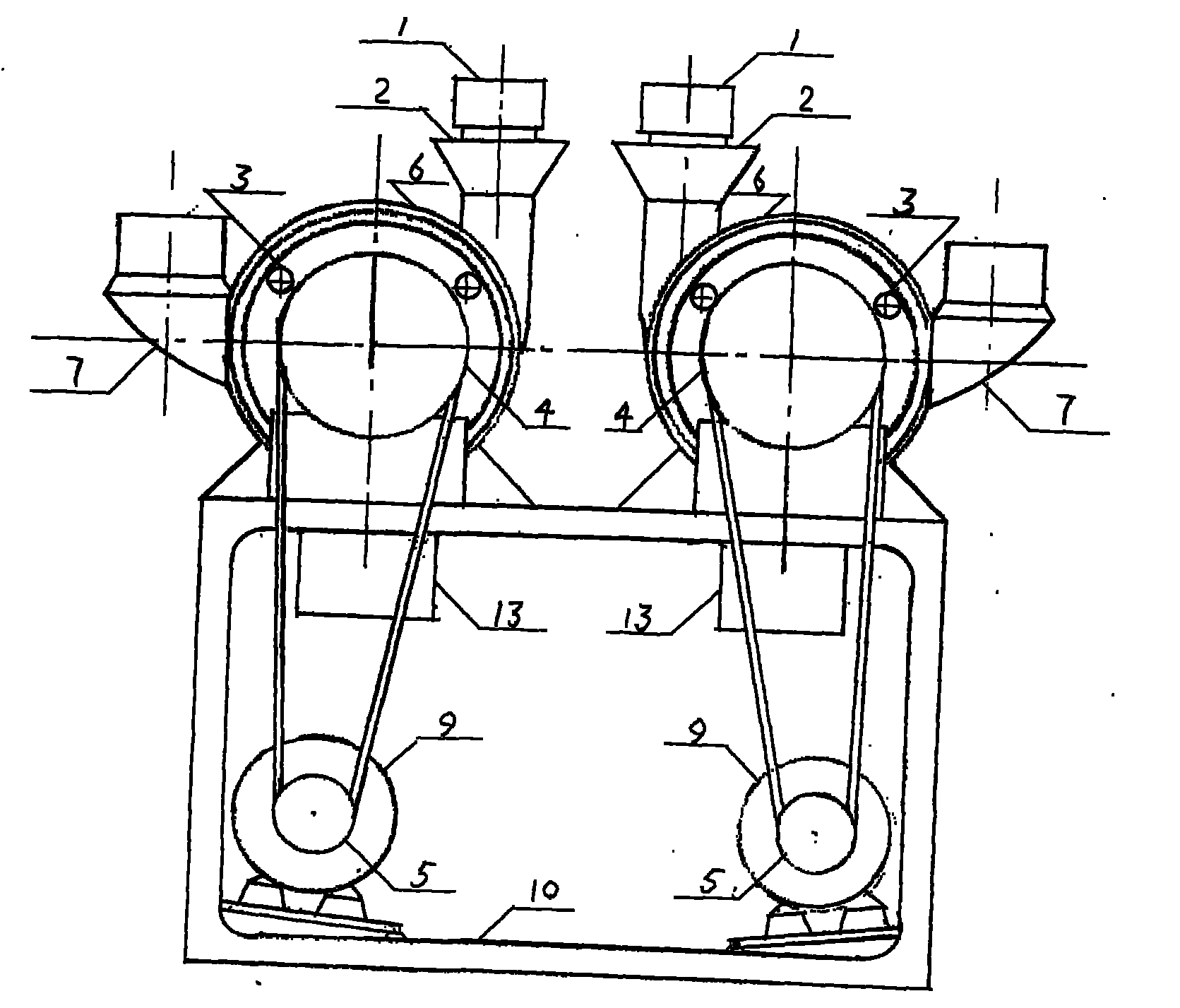

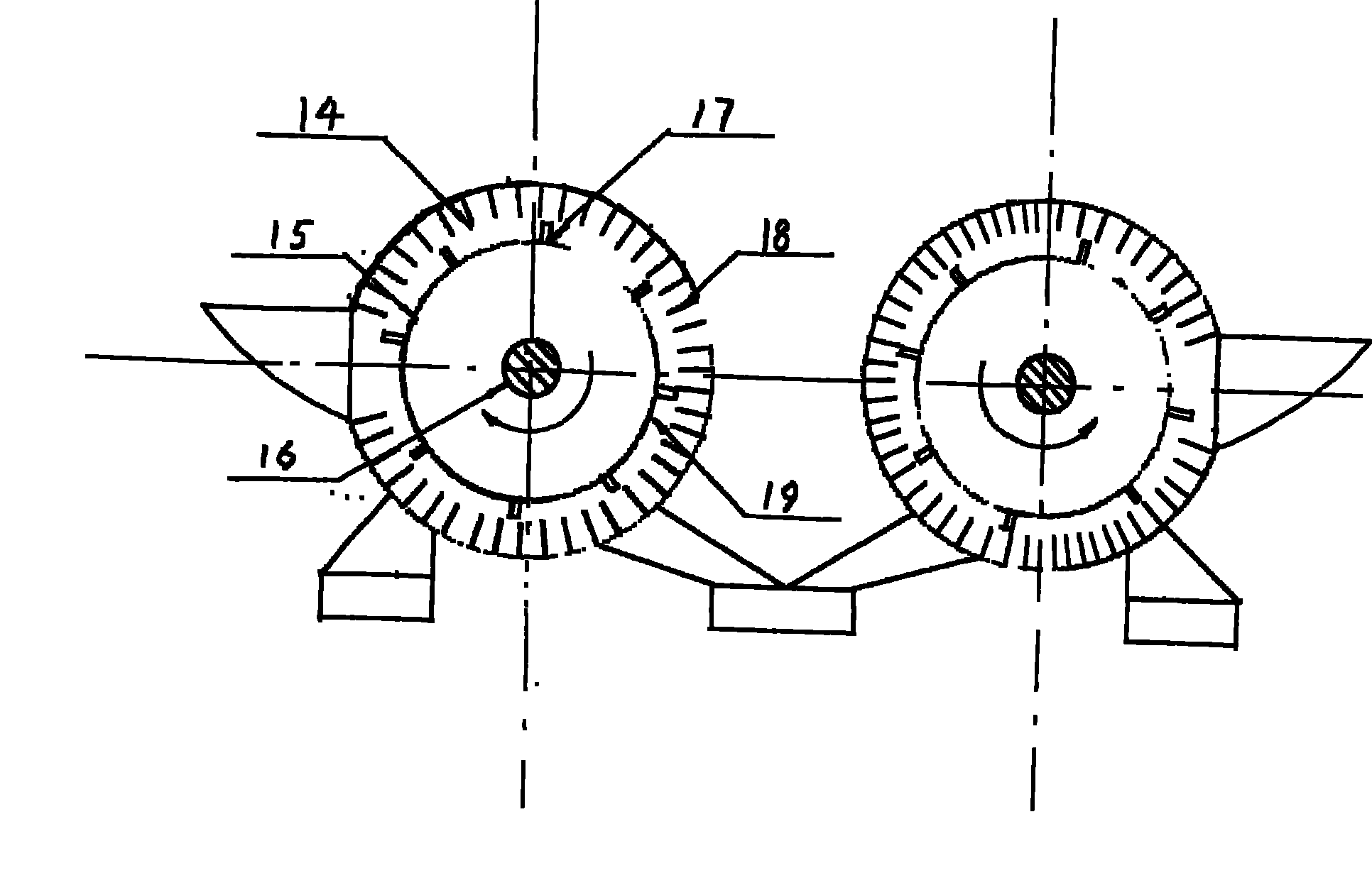

[0027] see Figure 1 to Figure 3 The bottom of frame (10) is provided with motor (9), and the top of frame (10) is provided with outer cylinder (6), and rotating cylinder (15) is located in the cavity of outer cylinder (6) and is connected with outer cylinder (6). ) circle centers overlap; along the inner wall of the outer cylinder (6) is provided with a steel wire row brush (18), and an inner circle working surface (14) is formed by the hair tip of the steel wire row brush (18), and the inner circle working surface (14) is connected with the rotary An annular space (19) is formed between the cylinders (15); there are brackets (17) with semicircular notches along the surface of the drum (15), and the brackets with three notches and the brackets with two notches are arranged alternately along the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com