Process and device for producing pyrotechnite from sodium sulfate decahydrate

A technology of sodium sulfate decahydrate and anhydrous mirabilite, which is applied to the device field of the process, can solve the problems of large investment scale of large-scale multi-effect evaporation devices, inability to deal with by-product thenardite, inability to invest in large-scale devices, etc. Small, small space required, investment saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

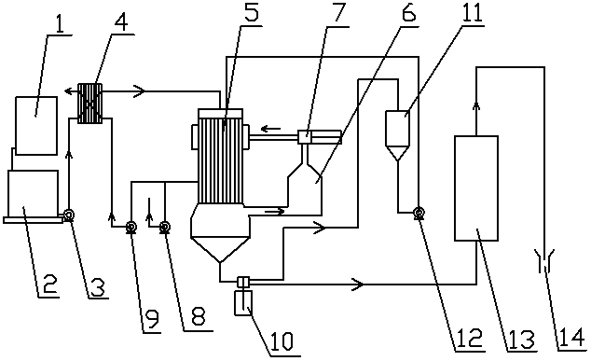

[0026] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

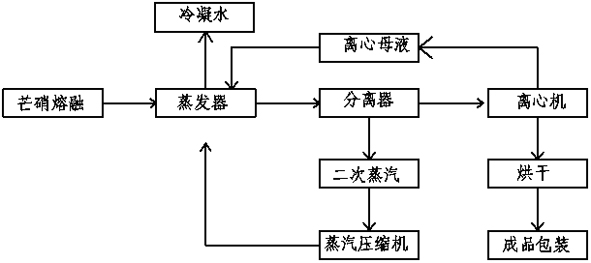

[0027] Such as figure 1 and figure 2 Shown, the technique of producing anhydrous Glauber's salt by sodium sulfate decahydrate comprises the following steps:

[0028] (1) Control the temperature in the hot-melt tank 1 at 33-90°C through the heating rod or heating coil in the Glauber’s salt hot-melt tank 1, put sodium sulfate decahydrate into the Glauber’s salt hot-melt tank 1 and melt to form sodium sulfate solution;

[0029] (2) The sodium sulfate solution obtained in step (1) is heated and transported into the evaporator 5, concentrated and evaporated in the evaporator 5, and part of the anhydrous sodium sulfate is crystallized;

[0030] (3) The secondary steam output from the evaporator 5 is compressed by the compressor 7, and the compression ratio is maintained at 1:1.2 to 1:2.5, so that the pressure, temperature and enthalpy of the steam are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com