Quasi one-dimensional nano structural thermoelectric material, device and preparation method thereof

A technology of thermoelectric materials and nanostructures, which is applied in the manufacture/processing of thermoelectric devices, parts and components of thermoelectric devices, etc., can solve the problems of no thermoelectric devices, achieve increased scattering, good thermal stability, and facilitate mass production and application Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

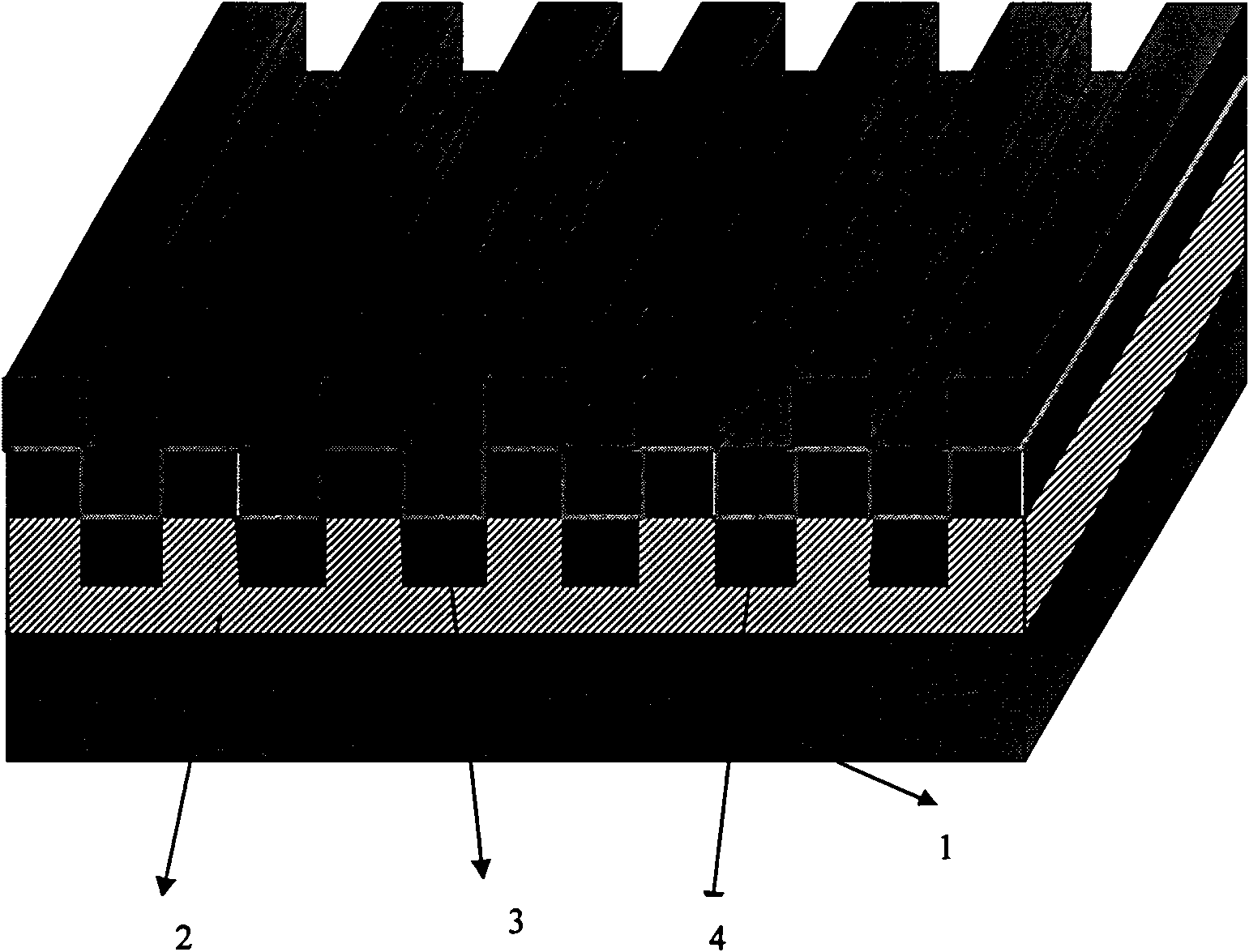

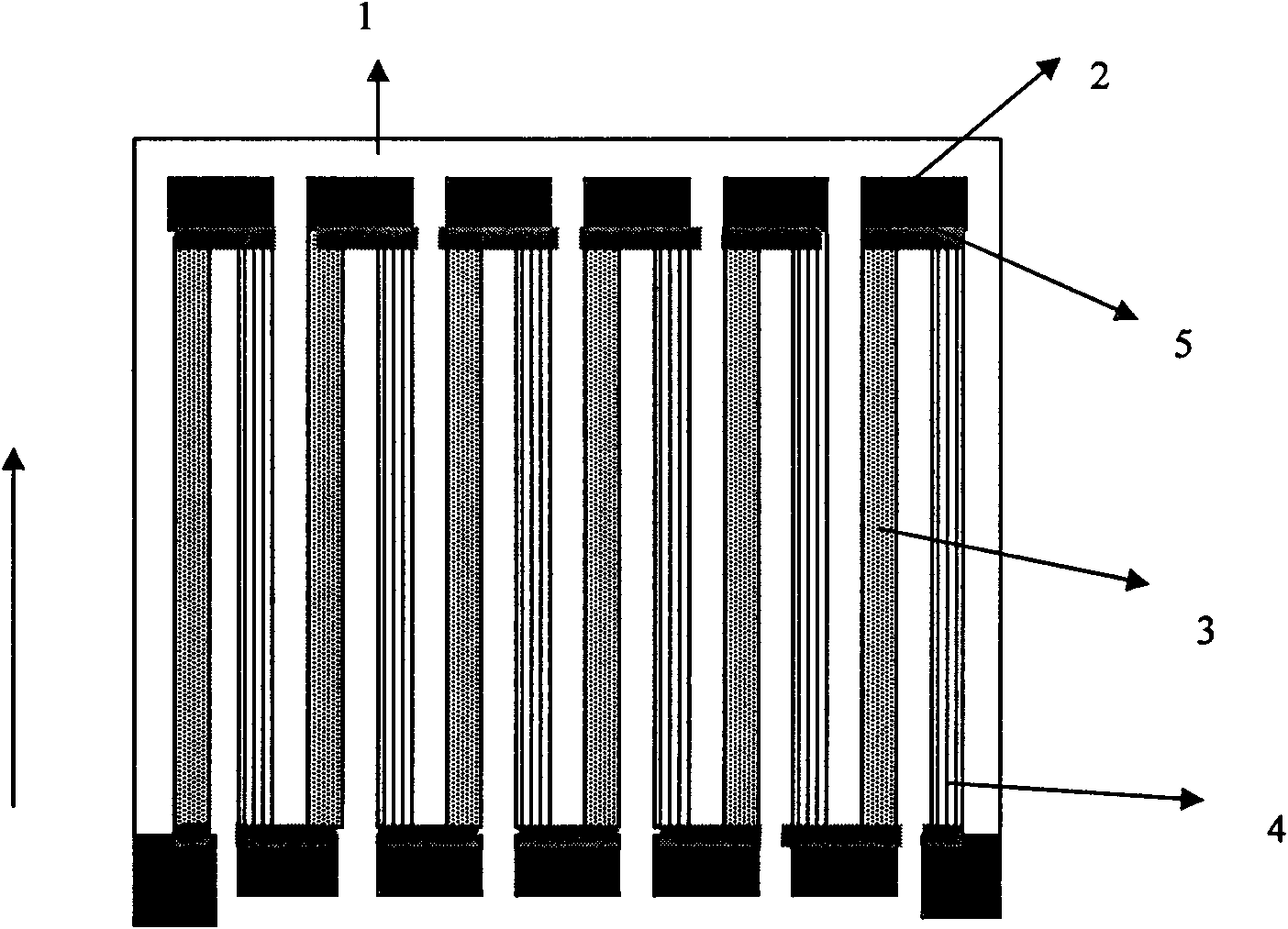

[0045] In this example, p-type and n-type Bi 2 Te 3 As a thermoelectric material, the thermoelectric layer doped with W particles is used as a phonon scattering layer, magnetron sputtering is used as a deposition method, and ultraviolet nanoimprinting technology is used as a method for preparing a grooved substrate, and the substrate is made of glass.

[0046] Specific steps are as follows:

[0047] (1) Apply embossing glue on a glass sheet (1cm×1cm) that has been ultrasonically cleaned by 1mol / L NaOH, 1mol / L Hcl solution, anhydrous ethanol, and deionized water, and the rectangular groove A template (20nm x 20nm in cross-section) is pressed on top, allowing UV light to pass through the template to cure the polymer. The template is separated from the substrate, and the residual polymer layer is removed to obtain a substrate with grooves (20nm×20nm).

[0048] (2) Place the substrate on the rotating substrate holder of the magnetron sputtering instrument, and install the p-typ...

Embodiment 2

[0056] In this example, p-type and n-type PbTe were selected as the thermoelectric material, the thermoelectric layer doped with SiO2 particles was used as the phonon scattering layer, the magnetron sputtering was used as the deposition method, and the ultraviolet nanoimprinting technology was used as the method for preparing the trench substrate. Means, the substrate uses mica.

[0057] Specific steps are as follows:

[0058](1) Apply embossing glue on the newly dissected mica sheet (1cm×1cm) that has been ultrasonically cleaned by 1mol / L NaOH, 1mol / L HCl solution, absolute ethanol, and deionized water. A template with rectangular grooves (5nm x 5nm) was pressed on top, allowing UV light to pass through the template to cure the polymer. The template is separated from the substrate, and the residual polymer layer is removed to obtain a substrate with grooves (5nm×5nm).

[0059] (2) Place the substrate on the rotating substrate holder of the magnetron sputtering instrument, i...

Embodiment 3

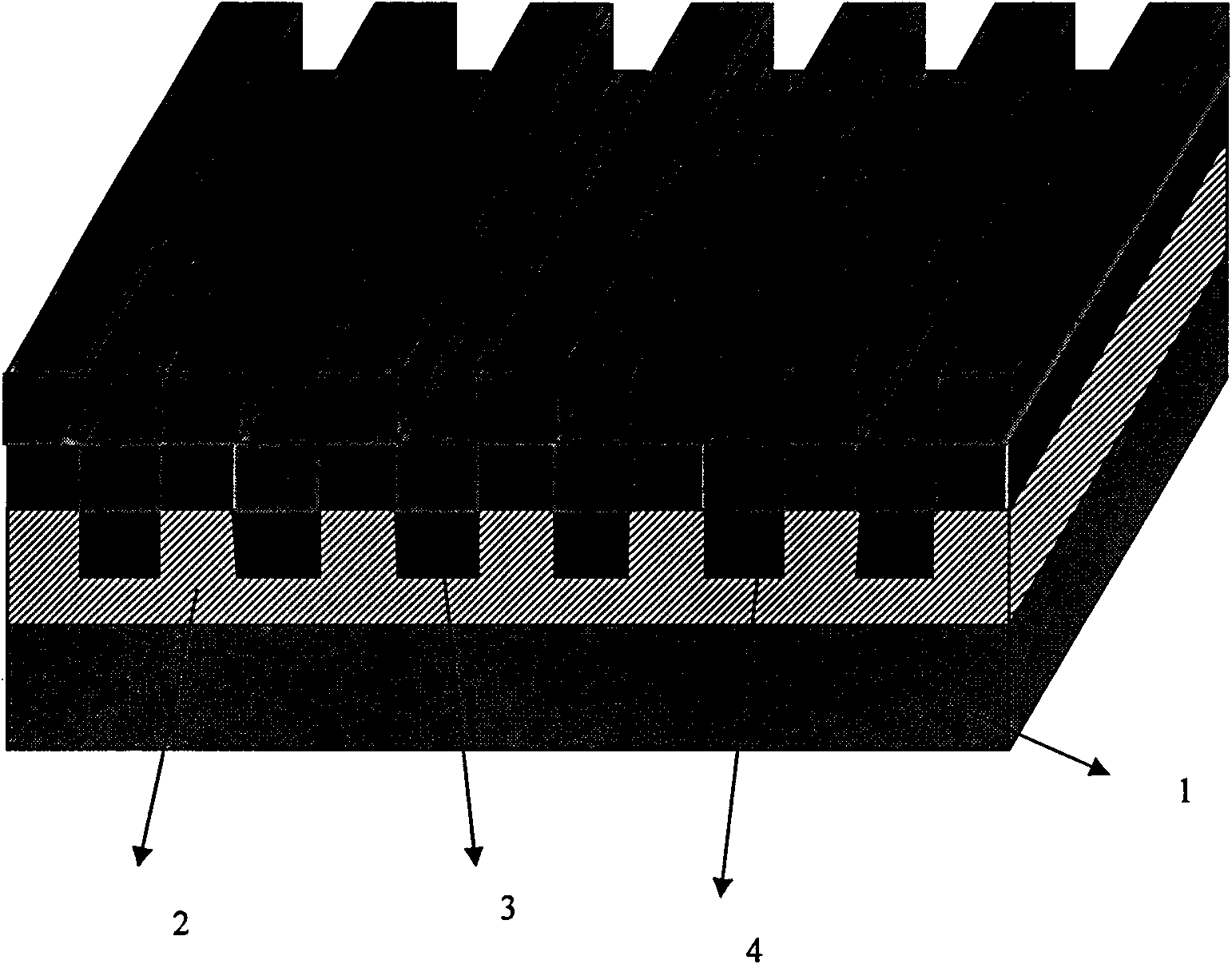

[0067] In this example, p-type and n-type Bi 2 Te 3 As a thermoelectric material, SiO 2 As a continuous layer of insulating material. Magnetron sputtering is used as a deposition method, and ultraviolet nanoimprint technology is used as a method for preparing grooved substrates, and silicon oxide wafers are used as substrates.

[0068] Specific steps are as follows:

[0069] (1) Take a silicon wafer (1cm×1cm), oxidize it, and then use 1mol / L NaOH, 1mol / L Hcl solution, absolute ethanol, and deionized water to clean it ultrasonically, and then apply the imprinting glue. A template with rectangular grooves (200nm x 200nm) was pressed onto it, allowing UV light to pass through the template to cure the polymer. The template is separated from the substrate, and the residual polymer layer is removed to obtain a substrate with grooves (200nm×200nm).

[0070] (2) Place the substrate on the rotating substrate holder of the magnetron sputtering instrument, install the Bi 2 Te 3 ta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com