High transmittance fine household porcelain and production technology thereof

A production process and technology of fine porcelain, which is applied in the field of high-transparency daily-use fine porcelain and its production technology, can solve the problems that ordinary raw materials cannot be used for one-time firing technology, and prepare high-transparency daily-use fine porcelain, etc., to achieve Good gloss, high strength, good thermal shock resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0021] A kind of fine porcelain for daily use with high light transmittance, its body includes the following mineral components (by weight): 25% of Guangxi porcelain clay, 10% of potassium feldspar, 10% of quartz powder, 40% of kaolin, 5% of clay, Alumina 5% and Bentonite 5%. Detected through analysis, the green body prepared contains following chemical composition (by weight percentage): SiO 2 55.68%, Al 2 o 3 29.78%, CaO2.34%, MgO0.24%, K 2 O2.42%, Na 2 O1.36%, Fe 2 o 3 0.14%, TiO 2 0.02%. Described Guangxi china clay ore contains following chemical composition (by weight percentage): SiO 2 60%, Al 2 o 3 22%, CaO5.5%, MgO0.6%, K 2 O0.15%, Na 2 O0.5%, Fe 2 o 3 0.15%, TiO 2 0.01%.

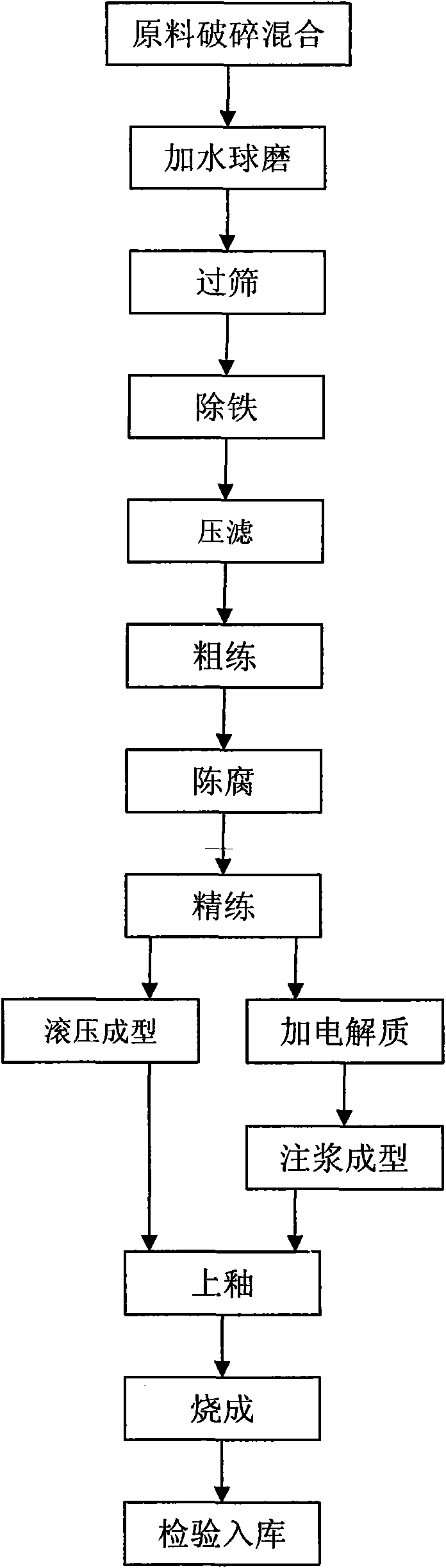

[0022] The production process of the high-transmittance daily-use fine porcelain is as follows: crush various mineral raw materials and mix them according to the ratio, add water and ball mill for 29 hours according to the ratio of material: water = 1:1, sieve with a 300-mesh stainl...

example 2

[0025] A kind of fine porcelain for daily use with high light transmittance, its body includes the following mineral components (percentage by weight): 28% of Guangxi porcelain clay, 8% of potassium feldspar, 9% of quartz powder, 38% of kaolin, 5% of clay, Alumina 5% and Bentonite 7%. Detected through analysis, the green body prepared contains following chemical composition (by weight percentage): SiO 2 55.96%, Al 2 o 3 29.69%, CaO2.45%, MgO0.28%, K 2 O2.32%, Na 2 O1.27%, Fe 2 o 3 0.12%, TiO 2 0.02%. The chemical composition of described Guangxi china clay ore is identical with embodiment 1.

[0026] The production process of this high-transmittance daily-use fine porcelain is as follows: crush various mineral raw materials according to the proportion and mix them, add water and ball mill for 28 hours according to the ratio of material: water = 1:1, sieve with a 300-mesh stainless steel screen, and remove iron , pressure filtration, the water content of the mud bar af...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com