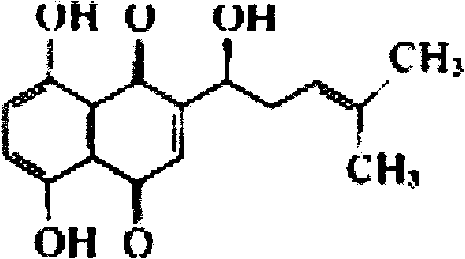

Method for extracting shikonin from lithospermum

A technology of shikonin and shikonin, applied in the directions of organic chemistry, quinone separation/purification, etc., can solve problems such as large processing capacity of toxic organic reagents, and achieve the effects of reducing crystallization and purification steps, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Take comfrey root raw material to remove impurities and crush, weigh 1kg and put it into a percolator, percolate with 20kgph9 sodium bicarbonate aqueous solution for 48 hours to obtain percolation liquid, adjust ph to 7 with 5% hydrochloric acid, add 1LXDA-1 macroporous resin for adsorption, and place a bet Then adjust the ph5 and ph3 adsorption twice, wash neutral, and then elute with 8L of 70% ethanol solution, recover the ethanol under reduced pressure and place it to crystallize, filter out to get coarse crystals, dissolve with ph11 sodium bicarbonate solution, filter, and adjust ph3 Precipitate, filter out the precipitate to obtain 65g, wash with 400ml hot water to obtain the crude product, then use acetone and ethyl acetate to reflux to dissolve and recrystallize, and dry at low temperature to obtain the product shikonin 15g with a content of 95%.

Embodiment 2

[0029] Take comfrey root raw material to remove impurities and crush, weigh 1kg and put it into a percolator, percolate with 15kgph11 sodium carbonate aqueous solution for 38 hours to obtain percolation liquid, adjust ph to 7 with 10% hydrochloric acid, add 1L XDA-8 macroporous resin for adsorption, and place a bet Then adjust ph5 and ph3 to absorb twice, wash with water, then elute with 6L of 80% ethanol solution, recover the ethanol under reduced pressure and place it to crystallize, filter out to get coarse crystals, dissolve with ph10 sodium bicarbonate solution, filter, adjust ph1 Precipitation, the precipitate was filtered out to obtain 78g, washed with 700ml of hot water to obtain a crude product, and then refluxing with acetone and ethyl acetate to dissolve and recrystallize, and dried at low temperature to obtain 19g of shikonin with a content of 98%.

Embodiment 3

[0031] Take comfrey root raw material to remove impurities and pulverize, weigh 1kg and put it into a percolator, percolate with 18kgph10 sodium hydroxide aqueous solution for 48 hours to obtain percolation liquid, adjust pH to 7 with 5% hydrochloric acid, add 1L LSA-7 macroporous resin for adsorption, The injection liquid is then adjusted to ph5 and ph3 and adsorbed twice, washed with water to be neutral, and then eluted with 7L of 75% ethanol solution. The ethanol is recovered under reduced pressure and placed to crystallize. The crude crystals are filtered out, dissolved in a ph11 sodium bicarbonate solution, and filtered. Adjust the ph1 to precipitate, filter out the precipitate to obtain 59g, wash with 500ml hot water to obtain the crude product, then use acetone and ethyl acetate to reflux to dissolve and recrystallize, and dry at low temperature to obtain the product shikonin 13g with a content of 94%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com