Method for preparing solid acrylic acid copolymer

A technology of solid acrylic acid and copolymer, which is applied in the field of preparation of solid acrylic acid copolymer, which can solve the problems of environmental pollution, energy consumption and time-consuming, and achieve the effects of broad application prospects, shortened reaction time and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

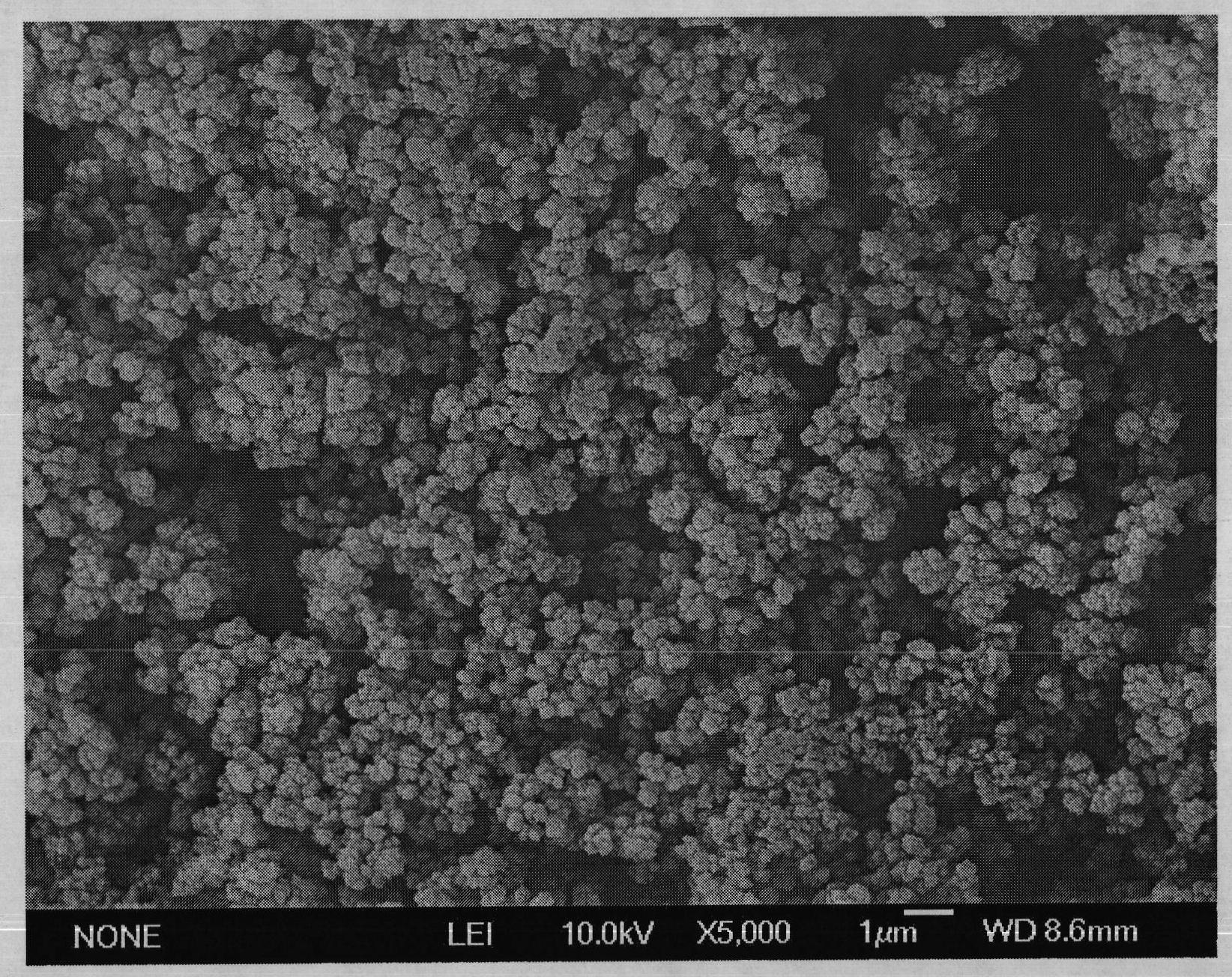

Image

Examples

preparation example Construction

[0020] A preparation method of a solid acrylic acid copolymer, wherein the method is to rapidly prepare a hydrophobically associative solid acrylic acid copolymer in supercritical carbon dioxide, and the reaction medium is supercritical carbon dioxide. The polymer monomers used are explosively polymerizable in supercritical carbon dioxide, or can be explosively polymerized with another monomer or monomers. It is one or more of acrylic acid, long-chain acrylic acid ester, and vinylpyrrolidone, styrene, and acrylamide. The polymers prepared in the present invention may be di- or terpolymers. The specific steps and process conditions are as follows:

[0021] Add acrylic acid, long-chain acrylic acid ester, and one of styrene, vinylpyrrolidone, and acrylamide into the autoclave. The acrylic acid, long-chain acrylic acid ester, and comonomer are in a molar ratio of 0.5-99.5:0.5-20:0.5-99.5, and then an initiator of 0.1-4.0 wt% of the total monomer weight is added. Put in a magne...

specific Embodiment approach 1

[0027] The invention proposes a method for rapidly preparing hydrophobically associative solid acrylic copolymer in supercritical carbon dioxide.

[0028] Weigh 2.0 g of acrylic acid, 0.021 g of initiator azobisisobutyronitrile, 0.12 g of octadecyl acrylate, and 0.1 g of vinylpyrrolidone into a 20 mL stainless steel autoclave, put in a magnetic stirrer, and seal; slowly fill in The carbon dioxide was reduced to 4Mpa, the air inlet was closed, and the air in the kettle was exhausted. Pour carbon dioxide into the autoclave with a high-pressure metering pump, increase the pressure of carbon dioxide to 9Mpa, then close the inlet and outlet valves, and heat in a water bath. Start the magnetic stirring, heat the water bath to 60°C, and when the temperature rises to the predetermined value of 60°C, if the pressure does not reach the predetermined value of 16Mpa, add or release carbon dioxide to make the pressure reach the required pressure. After 30 minutes of reaction, the system e...

specific Embodiment approach 2

[0030] Weigh 1.5 g of acrylic acid, 0.021 g of initiator azobisisobutyronitrile, 0.1 g of octadecyl acrylate; 0.5 g of vinylpyrrolidone was added to a 20 mL stainless steel autoclave, placed in a magnetic stirring bar, and sealed; slowly filled Carbon dioxide to 2Mpa, close the air inlet, and exhaust the air in the kettle. Pour carbon dioxide into the autoclave with a high-pressure metering pump, increase the pressure of carbon dioxide to 10Mpa, then close the inlet and outlet valves, and heat in a water bath. Start the magnetic stirring, heat the water bath to 60°C, and when the temperature rises to the predetermined value of 60°C, if the pressure does not reach the predetermined value of 18Mpa, add or release carbon dioxide to make the pressure reach the required pressure. After 15 minutes of reaction, the system exploded. In order to avoid the excessive increase of the pressure of the reactor by the explosion reaction, the reactor was cooled by water, and after the pressur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

| shear viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com