Large-scale fixed-bed biomass gasification power generation production process and complete sets of equipment

A fixed-bed gasifier and production process technology, applied in the chemical industry, biofuels, machinery and equipment, etc., can solve the problems of low thermal efficiency and conversion rate, difficulty in stable operation of equipment, low production capacity, etc. Chemical and power generation efficiency, convenient for industrial applications, and the effect of saving equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings. Those skilled in the art understand that the following specific implementation methods shall not be regarded as limitations to the present invention, and any improvement to the present invention does not deviate from the spirit of the present invention.

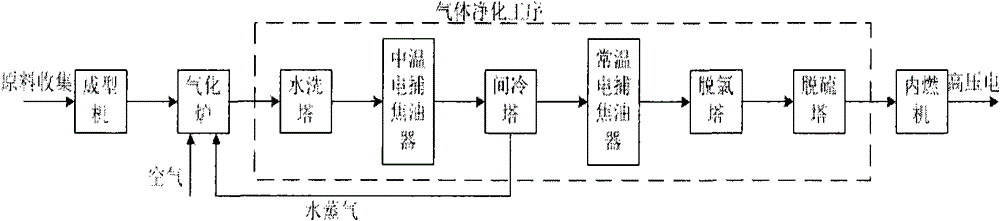

[0046] Such as figure 1 As shown, the collected biomass is compressed into a high-density rod (1.1-1.2kg / m 3 ) into the gasifier. The biomass gasification furnace has an inner diameter of 3m and a height of 3m, and can process 51 tons of compressed straw per day. Among them, the gasification furnace uses a mixture of air and water vapor (from the high-temperature water vapor discharged from the subsequent intercooling tower) as a gasification agent to flow upwards at the bottom of the gasification furnace. Countercurrent contact, fully react in the combustion layer to provide the heat requ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com