Curable resin composition for nanoimprint

一种固化性树脂、纳米压印的技术,应用在纳米技术、纳米技术、用于信息加工的纳米技术等方向,能够解决基体材料贴合性不充分、不适于形成图案等问题,达到提高模具剥离性、剥离性优异、贴合性好的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~11、 comparative example 1~3

[0163] 1) Coating film preparation method

[0164]

[0165] A 4-inch silicon wafer pre-treated with hexamethyldisilazane was used as the Si substrate material.

[0166]

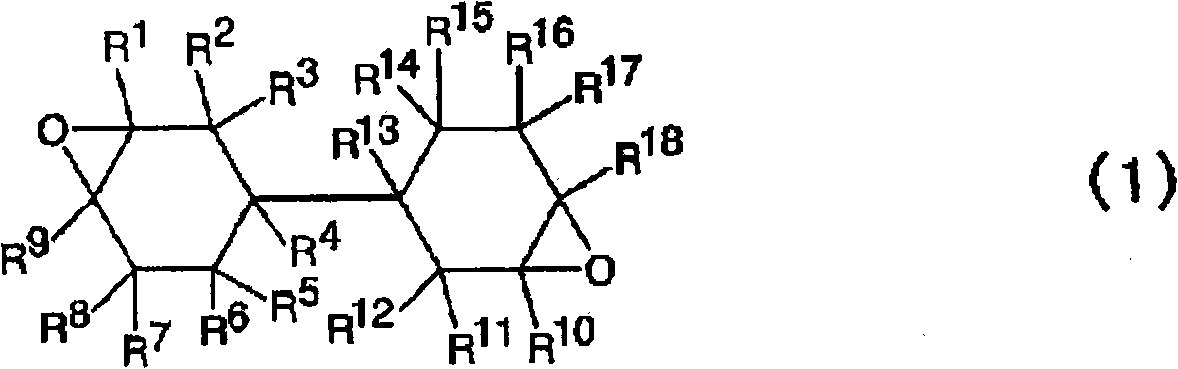

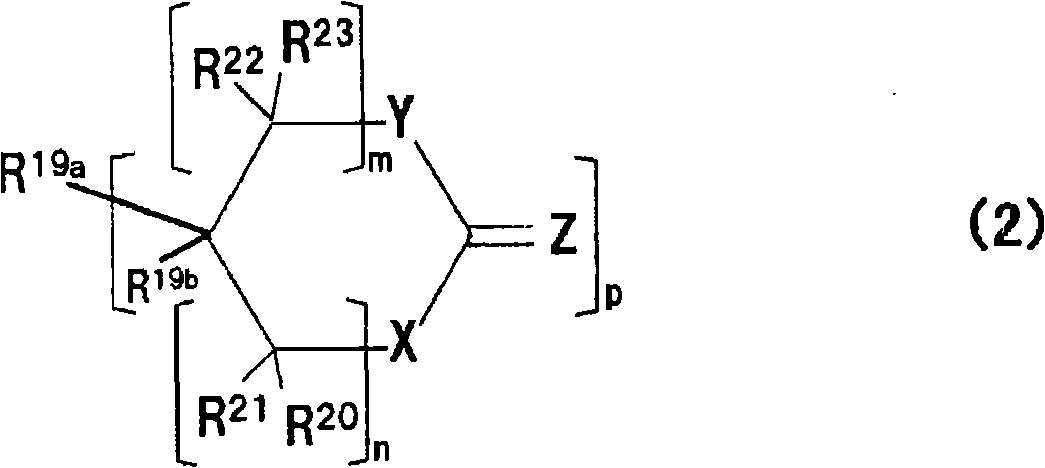

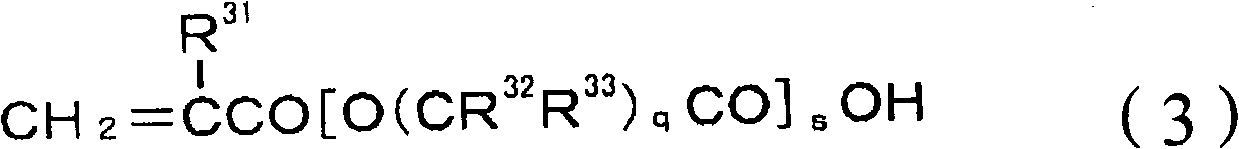

[0167] The photocurable resin composition for nanoimprinting is shown in Table 1, using a compound (A) having a reactive functional group and a hydrophobic functional group in the same molecular skeleton, a curable monomer (B), an initiator (C), an extender The sensitizer (D), nano-sized particles (E), binder resin (film forming aid: F), and solvent (G) were prepared by a known method with a spin coater. The specific compound of each component in Table 1 is shown below.

[0168] Compounds with reactive functional groups and hydrophobic functional groups in the same molecular skeleton: as shown in Table 2.

[0169] Curable monomer: as shown in Table 3.

[0170] Initiator

[0171] C-1: 4-methylphenyl[4-(1-methylethyl)phenyliodonium tetrakis(pentafluorophenyl)borate / PI2074 manufactured by ROHDEA / radiatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com