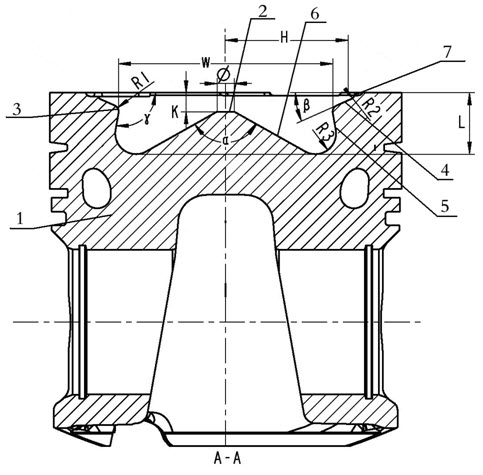

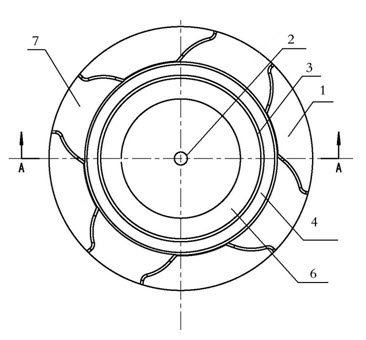

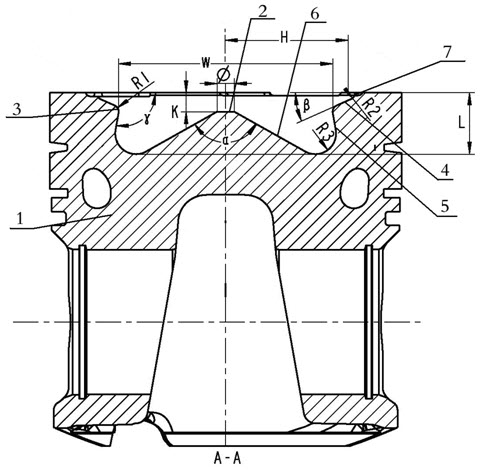

Diesel engine combustion chamber with concave-convex structure

A technology of concave-convex structure and combustion chamber, which is applied to combustion engines, mechanical equipment, engine components, etc., can solve the problems of low emission level, combustion, and increased fuel consumption, and achieve the effects of reducing emissions, uniform combustion, and improved performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below with reference to the accompanying drawings and in conjunction with the embodiments. The combustion chamber of the diesel engine with a concave-convex structure is located in the center of the upper part of the piston body 1. The center of the combustion chamber is a convex platform 2. There is an annular neck 3 around the combustion chamber. The annular neck divides the periphery of the combustion chamber into two parts: a slope surface 4 and a concave surface 5. , forming the entire combustion chamber. Ring neck diameter W=60mm, angle β=22° between the slope surface 4 and the horizontal line on the top surface of the piston body, arc length R1 of the transition section between the slope surface 4 and the concave surface 5=2mm. The angle γ=100° between the concave surface 5 and the horizontal line on the top surface of the piston body, the arc length R3 of the transition section between the concave surface 5 and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com