Process for large high-alloy steel resin bonded sand mould composite coating

A high-alloy steel, resin sand technology, applied in coatings, metal processing equipment, casting molds, etc., can solve problems affecting production progress, long time, rough surface of castings, etc., to increase sinterability and reduce thickness , the effect of improving dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

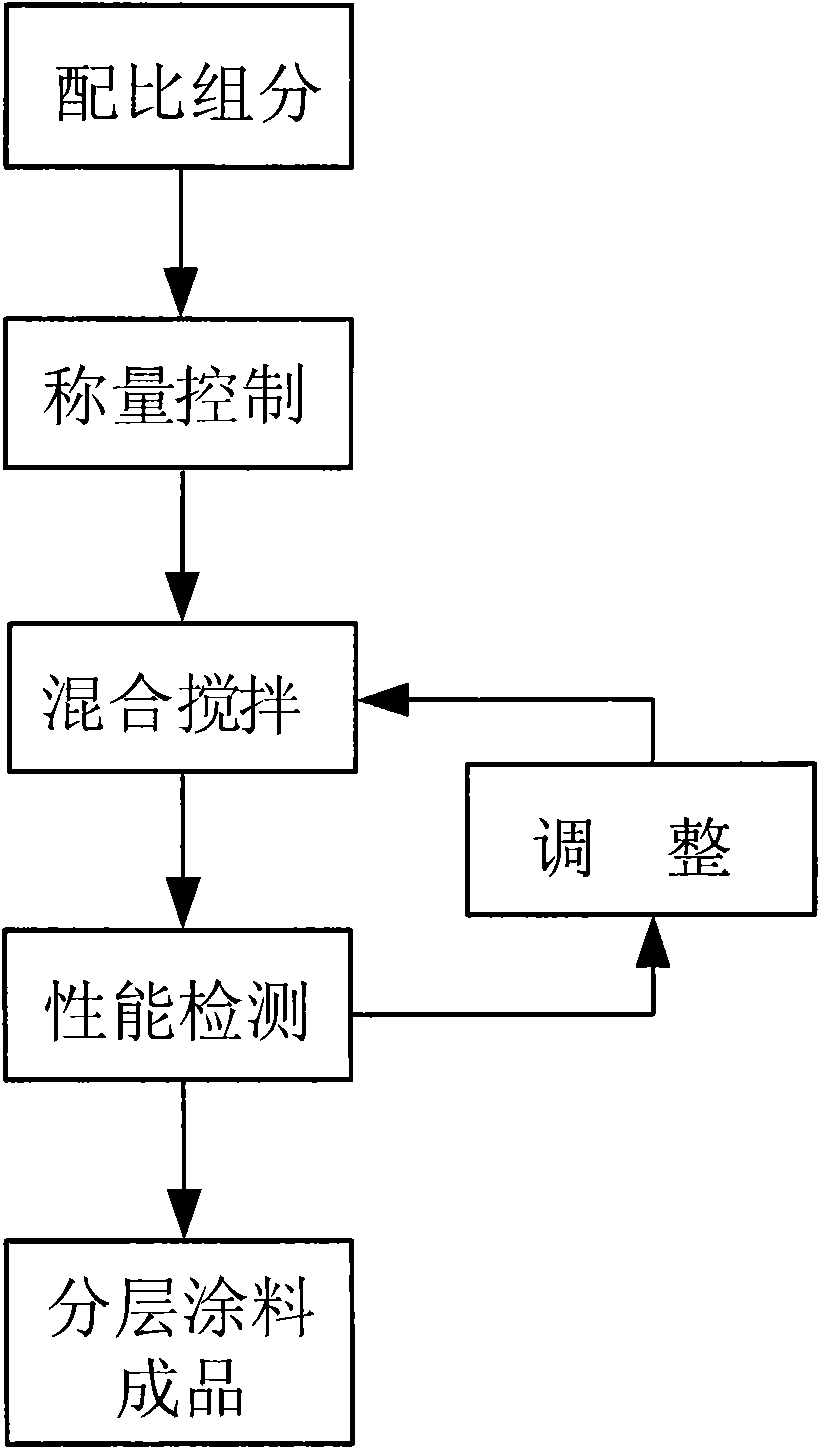

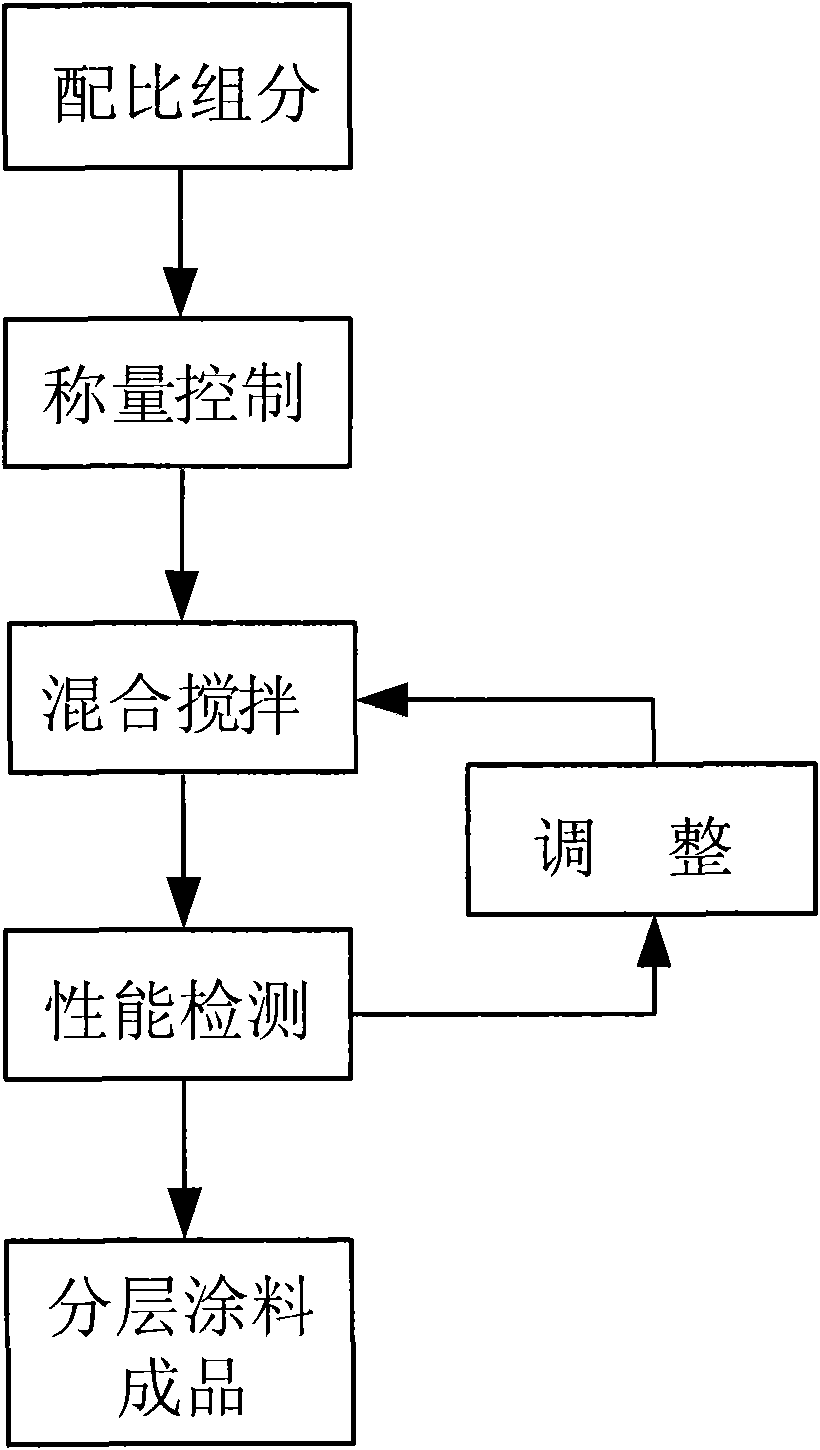

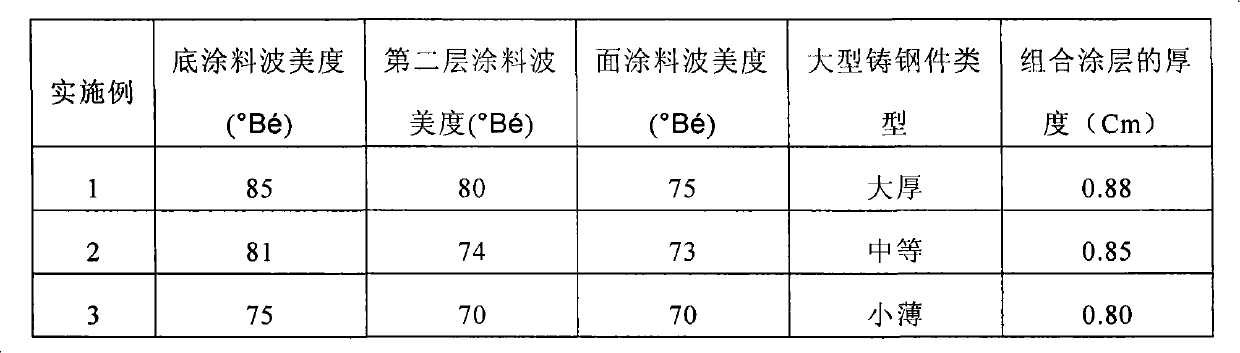

[0015] The combined paint layer process for large-scale high-alloy steel resin sand molds of the present invention is to brush the three-layer paint layers of primer, second layer paint and top paint on the inner cavity surface of the resin sand mold. First follow figure 1 The coating is prepared according to the method, and the weight percentage of each component of the primer is: 70% of zircon powder, 0.3% of oxidized rosin resin, 0.8% of thermoplastic phenolic resin, 1.5% of lithium bentonite, and 27.4% of isopropanol;

[0016] The second layer of coating components includes a composite refractory material composed of bauxite, zircon powder, and pyrophyllite, and the mixing ratio of its parts by weight is: 6:13:1, and the weight percentage of each component of the second layer of coating It is: 70% composite refractory material, 1.5% industrial sodium silicate, 1.5% sodium bentonite, 1% sodium dihydrogen phosphate, and the rest is water;

[0017] The percentage by weight o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com