Preparation method of coated aluminum powder

A technology of aluminum powder and coating, which is applied in the field of preparation of aluminum powder coating, can solve the problems of insufficient coating technology of aluminum powder and pigment, complex production process, etc., solve the problem of hydrogen evolution, simple production process, good acid and alkali resistance and glossy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

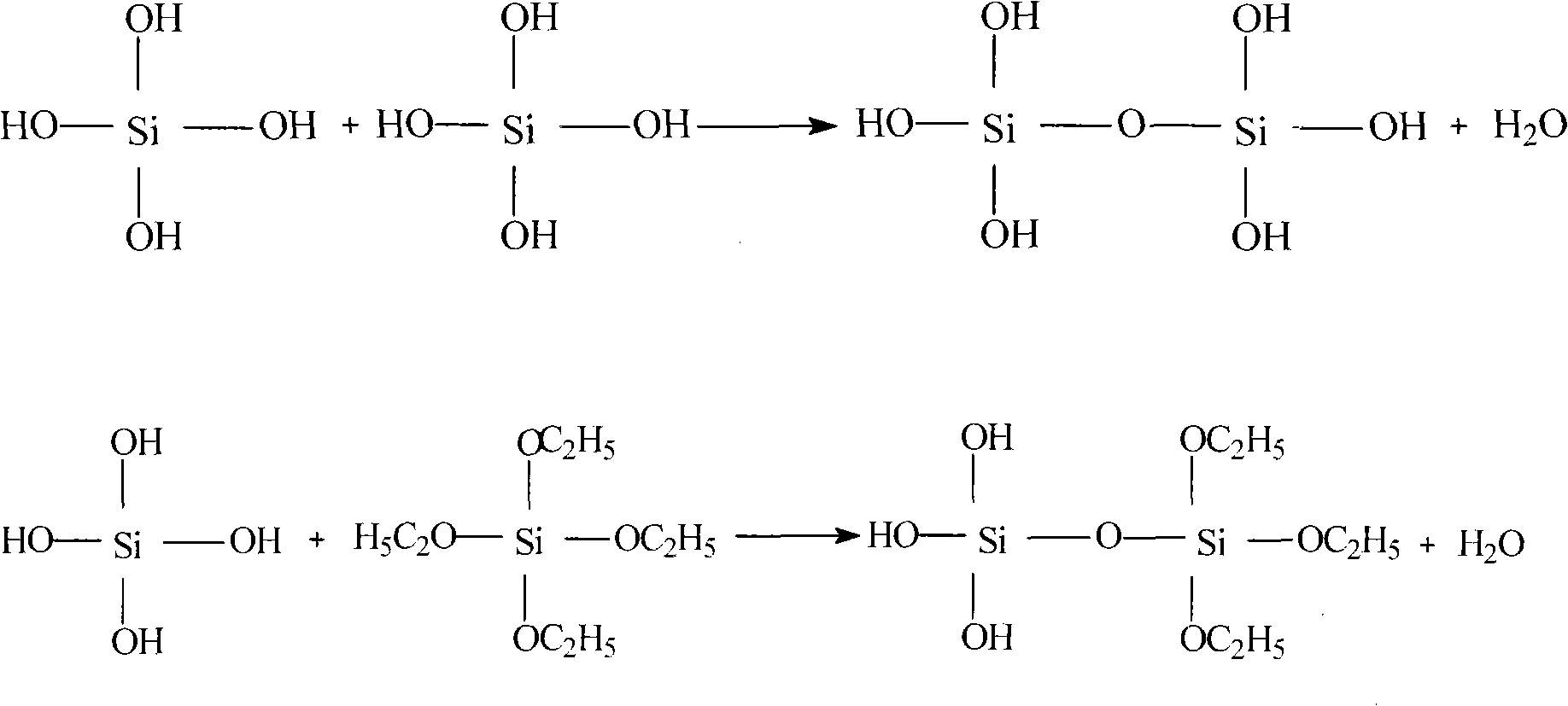

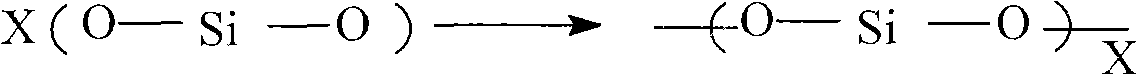

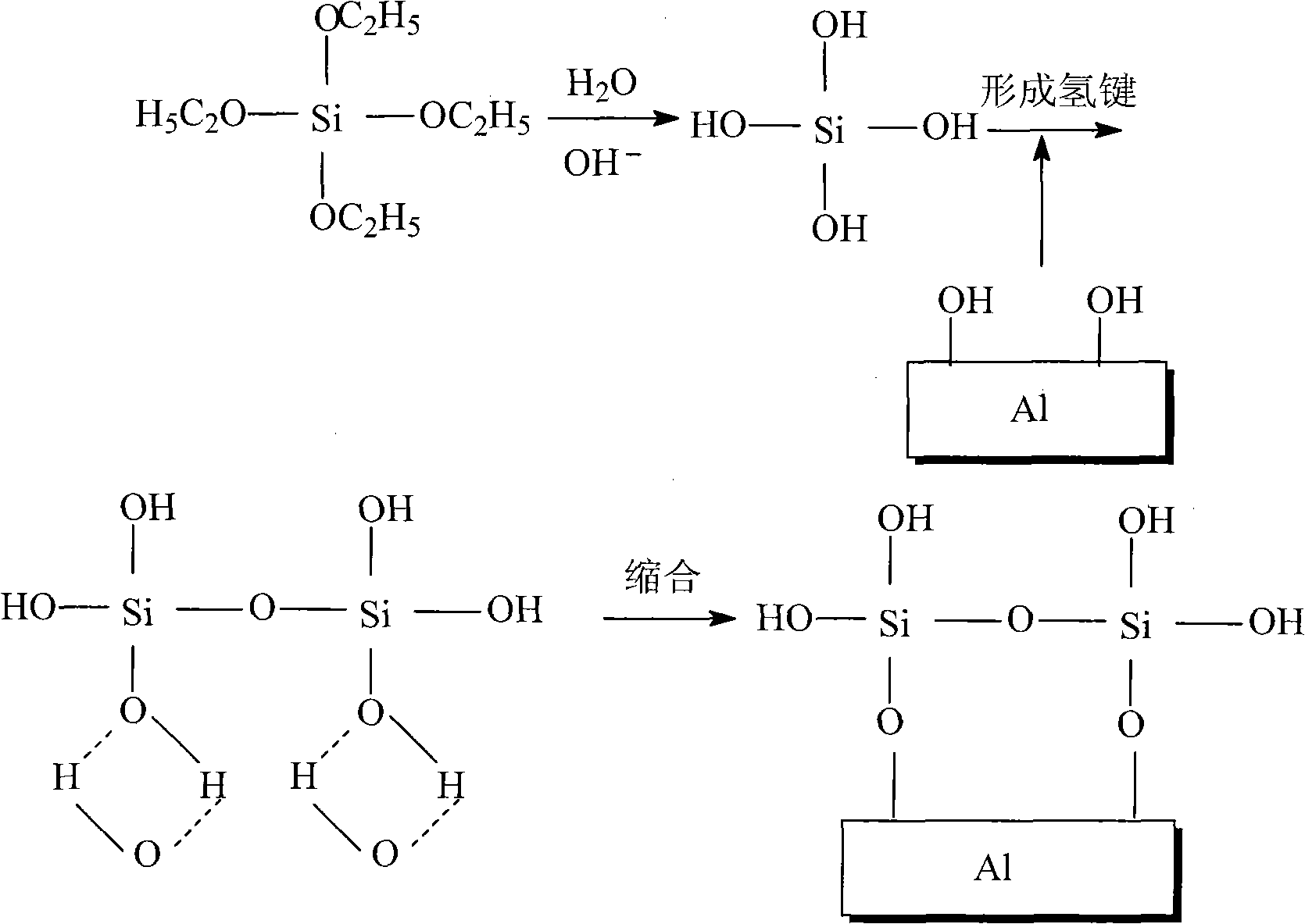

Method used

Image

Examples

Embodiment 1

[0033] In the first step, in parts by mass, 20 parts of aluminum powder pigments are dispersed in 90 parts of dissolved ethylene glycol butyl ether, and stirred at room temperature for 20 minutes.

[0034] In the second step, 27 parts of tetraethoxysilane were added into the reaction vessel of the first step, and stirred at room temperature for 20 minutes. Then, 65 parts of water were added, and the pH was adjusted to 8 with triethanolamine and acetic acid, and the mixture was reacted at room temperature for 2 hours.

[0035] The third step is to filter the aluminum powder and pigment suspension prepared in the second step, and repeatedly wash it with ethylene glycol butyl ether solvent to remove impurities in the reaction, and finally wash it with water for 3 to 5 times, and dry it in an oven at 50°C. Dry to obtain aluminum powder pigment coated with silica film.

[0036] The coated aluminum powder pigment was stored at room temperature for six months in the water-based pain...

Embodiment 2

[0038] In the first step, in parts by mass, 10 parts of aluminum powder pigments are dispersed in 45 parts of isopropanol, and stirred at room temperature for 30 minutes.

[0039] In the second step, 12 parts of triethoxysilane were added into the reaction container of the first step, and stirred at room temperature for 20 minutes. Then, add 25 parts of water, adjust the pH=9 with ethylenediamine and acetic acid, and react at room temperature for 3 hours.

[0040] The third step is to filter the aluminum powder and pigment suspension prepared in the second step, and repeatedly wash with isopropanol solvent to remove impurities in the reaction, and finally wash with water for 3 to 5 times, and dry it in an oven at 50°C. The aluminum powder pigment coated with silica film was prepared.

[0041] The coated aluminum powder pigments were stored at room temperature for six months in water-based paint systems with pH=4 and pH=9, no hydrogen gas was released, and good gloss was maint...

Embodiment 3

[0043] In the first step, in parts by mass, 15 parts of aluminum powder pigments were dispersed in 67.5 parts of ethanol, and stirred at room temperature for 20 minutes.

[0044] In the second step, 17 parts of dimethyldiethoxysilane was added into the reaction container of the first step, and stirred at room temperature for 20 minutes. Then, 40 parts of water was added, and pH=8 was adjusted with triethanolamine and acetic acid, and reacted at room temperature for 4 hours.

[0045] The third step is to filter the aluminum powder and pigment suspension prepared in the second step, and repeatedly wash with isopropanol solvent to remove impurities in the reaction, and finally wash with water for 3 to 5 times, and dry it in an oven at 50°C. The aluminum powder pigment coated with silica film was prepared.

[0046] The coated aluminum powder pigments were stored at room temperature for six months in water-based paint systems with pH=4 and pH=9, no hydrogen gas was released, and g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com