Method for synthesizing oxalic ester by CO coupling

A technology of oxalate and nitrite, applied in chemical instruments and methods, carbon monoxide or formate reaction preparation, organic chemistry, etc., can solve the problem of large radial temperature difference, catalyst overheating, and the selectivity of target product oxalate Low-level problems, to achieve the effect of good technical effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

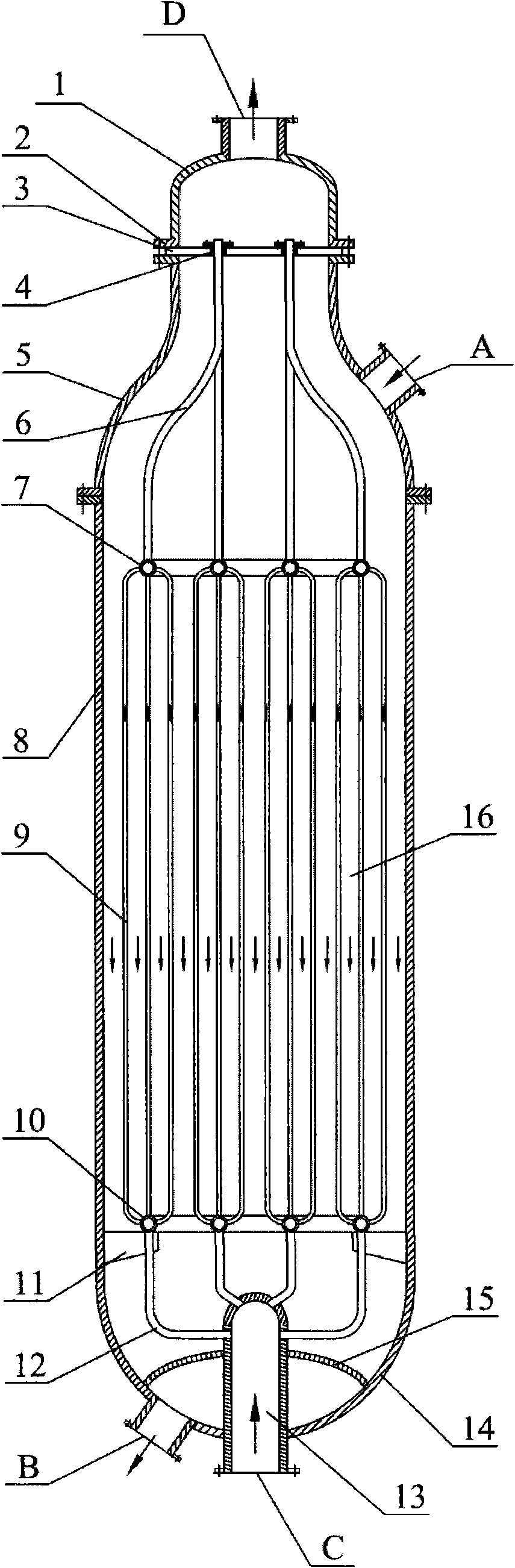

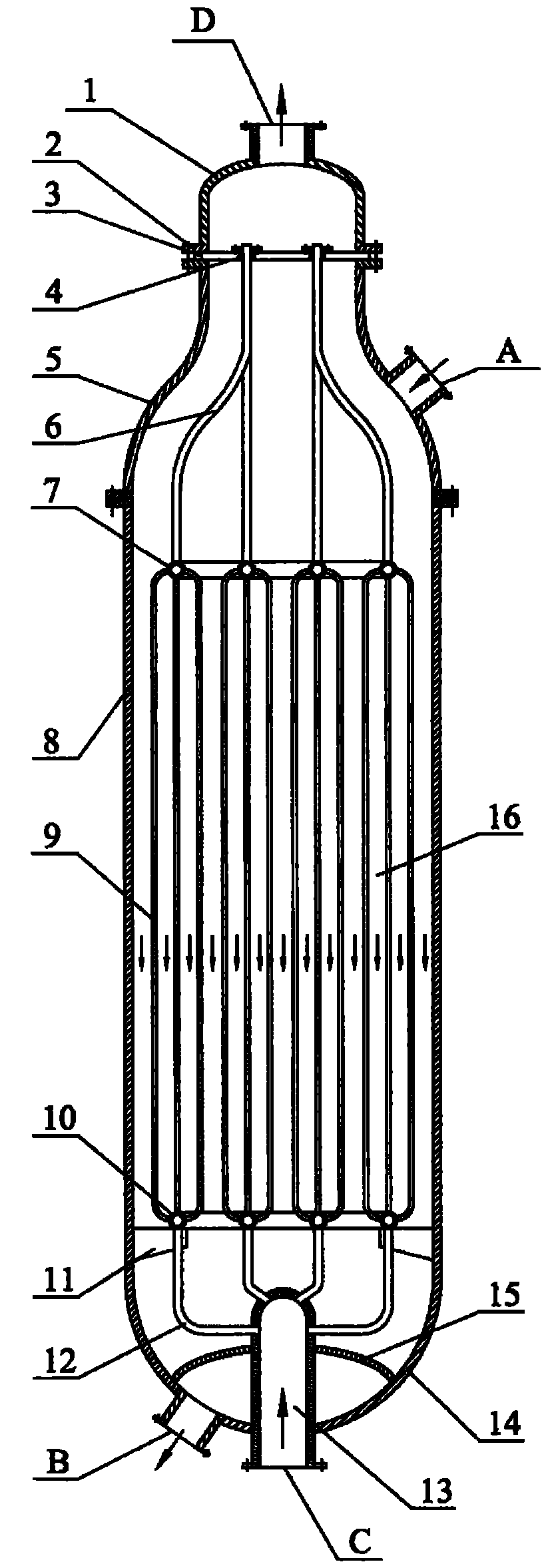

[0019] according to figure 1 , The inner diameter of the tubular fixed-bed reactor for CO coupling synthesis of dimethyl oxalate is 2 meters. The palladium-containing catalyst uses alumina as a carrier, and only supports palladium, and the amount of oxides selected from palladium is 0.8% by weight based on the weight of elemental palladium. The cooling medium is CO gas. The molar ratio of CO to methyl nitrite entering the reactor was 1.2:1. according to figure 1 In the process, the raw material gas containing CO and methyl nitrite enters the reactor through the raw material inlet. Under the conditions of the reaction temperature of 110 ° C, the reaction pressure of 0.1 MPa, and the contact time of 1 second, it is mixed with the catalyst bed outside the tube. The palladium-containing catalyst in the layer contacts and reacts, and the heat of reaction is absorbed by the cooling gas in the tube to generate a reaction effluent containing dimethyl oxalate. After the CO-containi...

Embodiment 2

[0021] according to figure 1 , The inner diameter of the tubular fixed-bed reactor for CO coupling synthesis of dimethyl oxalate is 2.5 meters. The palladium-containing catalyst is Pd-Ni / Al 2 o 3 Catalyst, based on the weight of elemental palladium, the amount of oxides selected from metal palladium and palladium is 0.5% by weight, the auxiliary agent Ni is based on the weight of elemental nickel, and the amount of oxides selected from nickel is 0.8% by weight %. The cooling medium is a mixed gas of methyl nitrite and CO. The molar ratio of CO to methyl nitrite entering the reactor was 1.5:1. according to figure 1 In the process, the raw material gas containing CO and methyl nitrite enters the reactor through the raw material inlet. Under the conditions of the reaction temperature of 140 ° C, the reaction pressure of 0.5 MPa, and the contact time of 2 seconds, it is mixed with the catalyst bed outside the tube. The palladium-containing catalyst in the layer contacts and ...

Embodiment 3

[0023] according to figure 1 , The inner diameter of the tubular fixed-bed reactor for CO coupling synthesis of diethyl oxalate is 2.5 meters. The palladium-containing catalyst is Pd-Ce / Al 2 o 3 The catalyst is based on the weight of elemental palladium, and the amount of the oxide selected from palladium is 1% by weight, and the auxiliary agent Ce is based on the weight of elemental cerium, and the amount selected from the oxide of cerium is 1.2% by weight. The cooling medium is ethyl nitrite. The molar ratio of CO and ethyl nitrite entering the reactor was 2:1. according to figure 1 In the process, the raw material gas containing CO and ethyl nitrite enters the reactor through the raw material inlet. Under the conditions of the reaction temperature of 120 ° C, the reaction pressure of 1.0 MPa, and the contact time of 3 seconds, it is mixed with the catalyst bed outside the tube. The palladium-containing catalyst in the layer contacts and reacts, and the heat of reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com