Hydrophilic modification method for macromolecular filter membrane and obtained product

A polymer membrane, hydrophilic technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc. Surface unevenness and other problems, to achieve the effects of high moisture retention and pollution resistance, simple operation and post-processing, and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 Modified polyethersulfone (PES) filter membrane (filter membrane 1)

[0036] Put the PES (weight-average molecular weight=410,000) filter membrane into deionized water and rinse it 5 times. Soak the PES filter membrane in an aqueous solution containing 80% (w / w) ammonium persulfate and 1.6% (w / w) N, N'-methylenebisacrylamide until saturated adsorption; soak the PES filter membrane The aforementioned aqueous solution was placed under an ultraviolet lamp with a wavelength of 300nm and irradiated for 10 seconds, then taken out and washed with deionized water several times before testing.

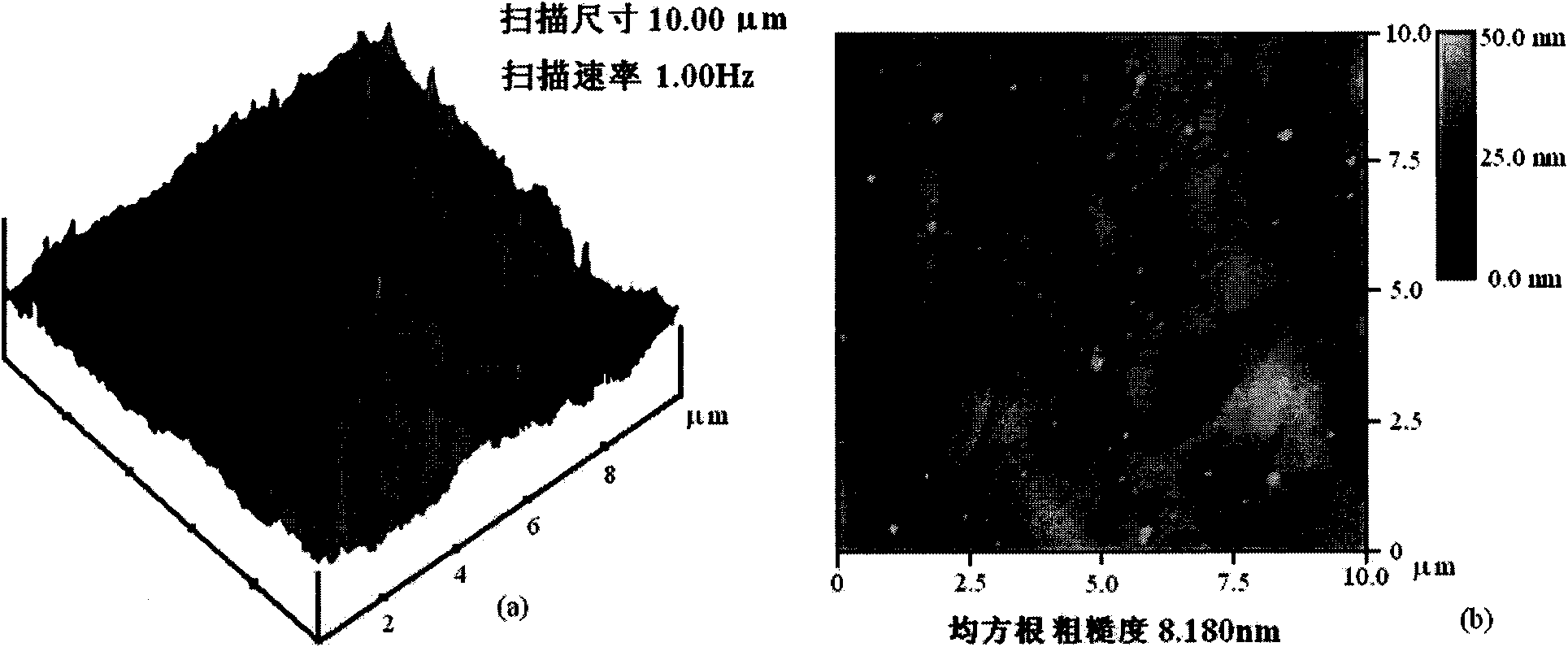

[0037] The modified PES filter membrane was subjected to atomic force microscopy ( figure 1 ), contact angle measuring instrument, and constant pressure water flux measuring device analysis, the surface of the PES filter membrane is smooth and hydrophilic. The test results of anti-bovine serum albumin (BSA) pollution performance show that, under 0.2MPa nitrogen pressure, a...

Embodiment 1

[0038] Comparative example 1 blank polyethersulfone (PES) filter membrane (contrast 1)

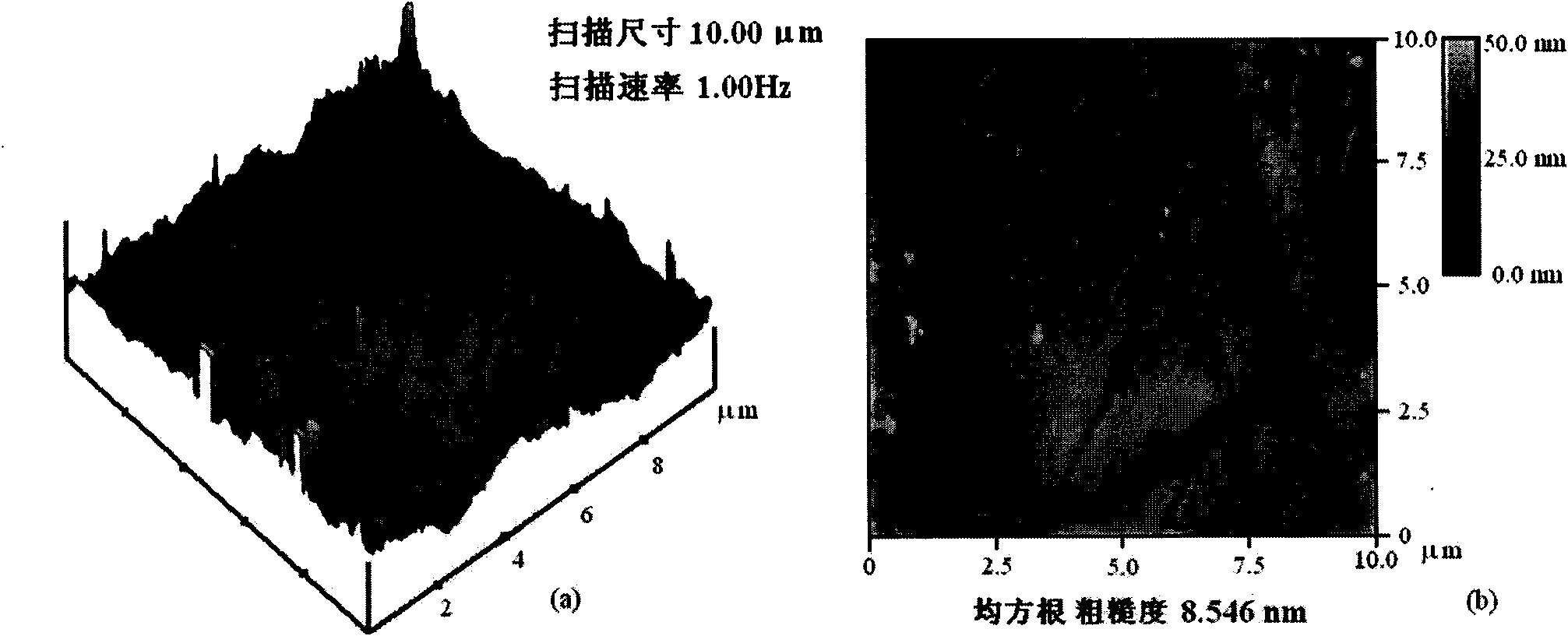

[0039] The unmodified PES filter membrane was subjected to atomic force microscopy ( figure 2 ), contact angle measuring instrument, constant pressure water flux measuring device analysis, PES membrane surface hydrophilicity is poor. The results of the anti-BSA pollution performance test show that the PES filter membrane has a very low washable recovery water flux percentage, indicating that the PES filter membrane has poor anti-pollution ability to BSA. The performance test results of the obtained PES filter membrane are shown in Table 1.

Embodiment 2

[0040] Embodiment 2 Modified polyvinylidene fluoride (PVDF) filter membrane (filter membrane 2)

[0041] The polyvinylidene fluoride (PVDF) (weight average molecular weight = 680,000) filter membrane was rinsed in deionized water for 5 times. The polyvinylidene fluoride (PVDF) filter membrane is soaked in the aqueous solution containing 15% (w / w) potassium bisulfate compound salt and 0.2% (w / w) cross-linking agent DE until saturated adsorption; The aforementioned aqueous solution with a polyvinylidene fluoride (PVDF) filter membrane was placed under a 254nm wavelength ultraviolet lamp and irradiated for 20 minutes, then taken out and washed with deionized water several times before testing.

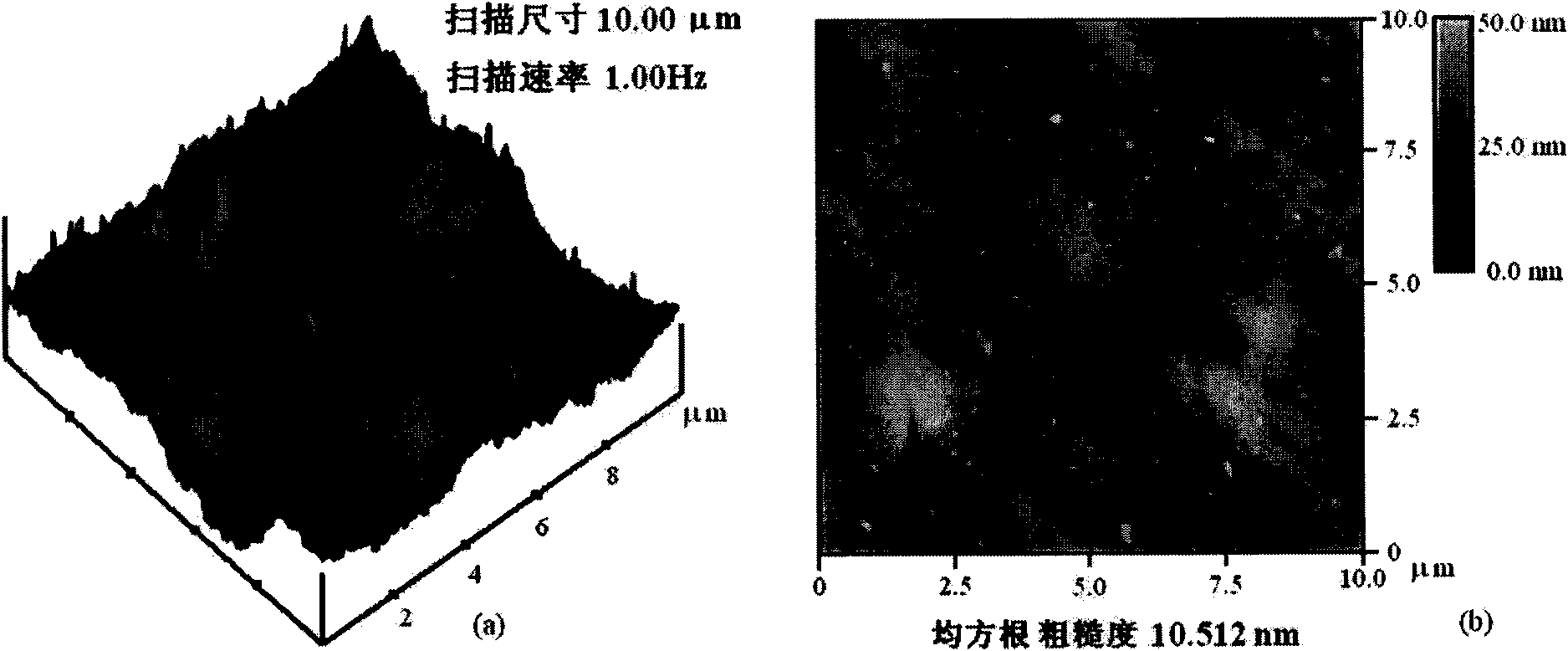

[0042] The prepared polyvinylidene fluoride (PVDF) membrane was examined by atomic force microscopy ( image 3 ), contact angle measuring instrument, and constant pressure water flux measuring device analysis, the filter membrane has a smooth surface and good hydrophilicity. The test re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

| Power | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com