Modified zinc oxide-loaded cobalt catalyst and preparation method thereof

A technology of cobalt catalyst and zinc oxide, which is applied in the field of modified zinc oxide-supported cobalt Fischer-Tropsch synthesis catalyst and its preparation, and can solve the problems of insufficient economic efficiency in the selectivity process of catalyst active products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

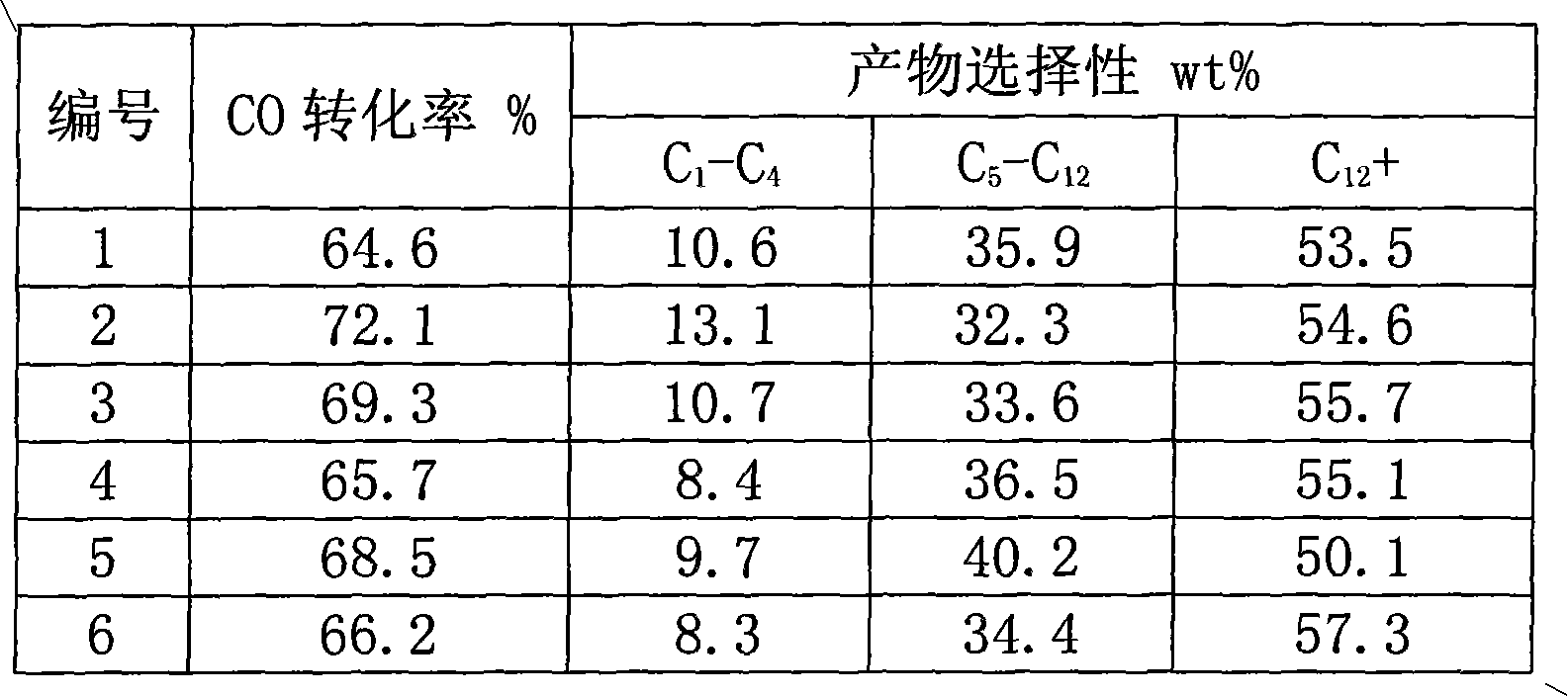

Examples

Embodiment 1

[0022] The modified zinc oxide supported cobalt catalyst was prepared according to the ratio of Co:W:Zn=5:30:36. Prepare 0.1M zinc acetate ethanol solution, prepare 0.5M ammonia solution as a precipitant, precipitate zinc salt at pH=6.0, 40°C, wash the filter cake to neutral, dry at 80°C, and roast at 300°C for 5 After hours, the obtained sample was broken into powders below 200 mesh for use. According to the set ratio, ammonium paratungstate aqueous solution was prepared, and tungsten was loaded on the obtained sample by the equal volume method, dried at 80°C, and roasted at 500°C for 3 hours, and the obtained sample was broken into powder below 200 mesh before use. Prepare a mixed solution of lanthanum nitrate and cobalt nitrate according to the amount of La accounting for 0.01 wt% in the final catalyst and cobalt. The cobalt is loaded by the equal volume method. The sample is dried at 80°C and calcined at 400°C for 3 hours to obtain the target catalyst. Catalyst compositio...

Embodiment 2

[0024] The modified zinc oxide supported cobalt catalyst was prepared according to the ratio of Co:W:Zn=5:45:48. Prepare 1.0M zinc acetate aqueous solution, prepare 1.5M ammonia solution as a precipitant, precipitate zinc salt at pH=9.0, 60°C, wash the filter cake until neutral, dry at 120°C, and roast at 500°C for 3 hours , The resulting sample was broken into powder below 200 mesh for later use. According to the set ratio, ammonium paratungstate aqueous solution was prepared, tungsten was loaded on the obtained sample by the equal volume method, dried at 120°C, and calcined at 500°C for 3 hours, and the obtained sample was broken into powder below 200 mesh before use. According to the amount of Ce accounting for 1.5wt% and cobalt in the final catalyst, a mixed solution of cerium nitrate and cobalt nitrate was prepared, and the cobalt was loaded by the equal volume method. The sample was dried at 100°C and calcined at 500°C for 3 hours to obtain the target catalyst. Catalyst...

Embodiment 3

[0026] The modified zinc oxide supported cobalt catalyst was prepared according to the ratio of Co:W:Zn=18:30:36. Prepare 1.0M zinc nitrate aqueous solution, prepare 1.0M ammonia solution as precipitant, precipitate zinc salt at pH=8.0, 80°C, wash the filter cake until neutral, dry at 100°C, and roast at 400°C for 4 hours , The resulting sample was broken into powder below 200 mesh for later use. According to the set ratio, the ammonium tungstate pentahydrate aqueous solution was prepared, and the obtained sample was loaded with tungsten by the equal volume method, dried at 100°C, and roasted at 300°C for 5 hours. The obtained sample was crushed into a powder below 200 mesh before use. According to the amount of Cr accounting for 8wt% and cobalt in the final catalyst, a mixed solution of chromium nitrate and cobalt nitrate was prepared, and the cobalt was loaded by the equal volume method. The sample was dried at 100°C and calcined at 450°C for 3 hours to obtain the target cat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com