A Combined Coating Layer Technology for Water Glass Sand Mold of Large Steel Castings

A technology for water glass sand and steel castings, which is applied to coatings, molds, cores, etc., can solve the problems of rough surface of castings, long time, affecting the progress of production, etc., and achieves improved dimensional accuracy and reduced thickness. , good leveling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

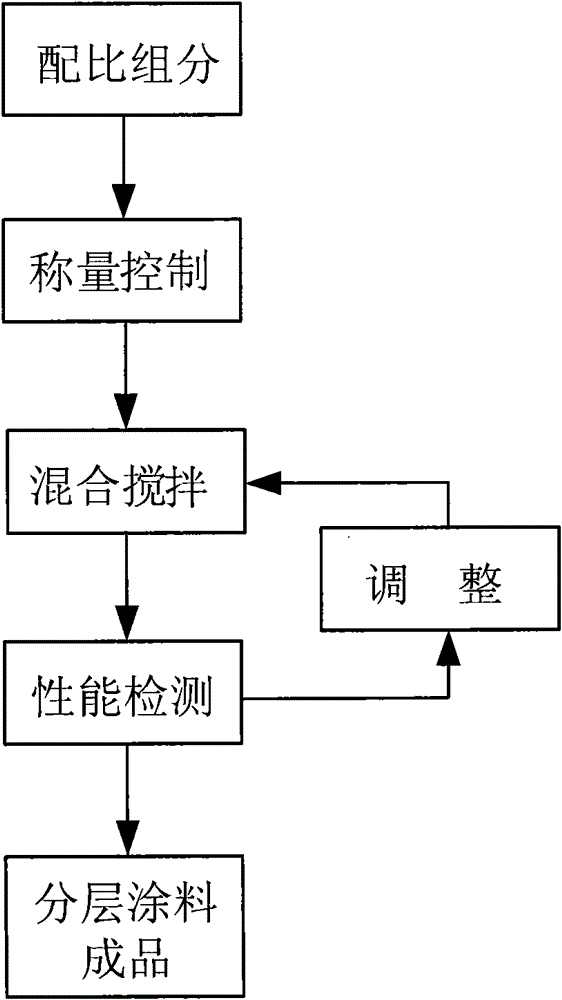

[0014] The composite coating layer process for the sodium silicate sand mold of large steel castings of the present invention is to apply three coating layers of primer, second coating and top coating on the surface of the inner cavity of the sodium silicate sand mold. First follow figure 1 The method of preparing the paint, the primer and the second layer of paint are the same, and the weight percentage of each component is: zircon powder 70%, oxidized rosin resin 0.3%, thermoplastic phenolic resin 0.8%, lithium bentonite 1.5%, isopropyl Alcohol 27.4%; the weight percentage of each component of the outermost layer coating is: zircon powder 74%, tertiary vinegar emulsion 2.2%, suspending agent 2.5%, associative thickener 1.5%, and the remaining components are water.

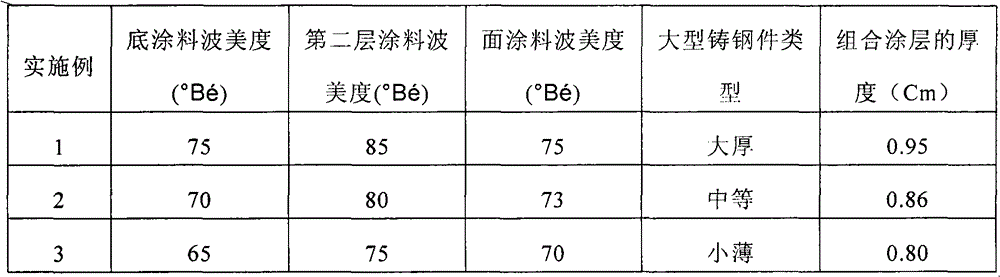

[0015] Then, in the process of painting the paint in the casting cavity, the base paint is controlled to have a Baume degree of 65~75°Bé during painting, and the Baume degree is adjusted with an industrial alcohol c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com