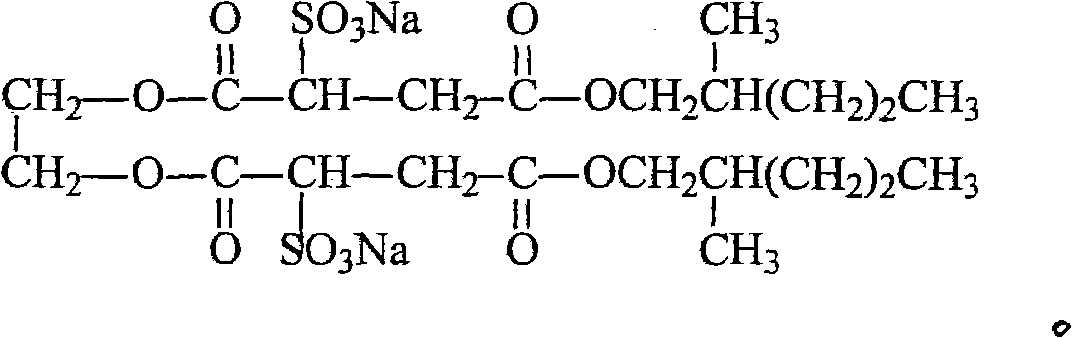

Ethylene glycol bi-sulpho succinic acid bi(2-methyl amyl) artesunate and production method thereof

A technology of bissulfosuccinic acid and methyl amyl, which is applied in the preparation of sulfonates, chemical instruments and methods, organic chemistry, etc., can solve the problems of complex production, lack of working performance of surfactants, and lack of scope of use, and achieves Reduce pollution, reduce the investment of solvent recovery treatment process and extraction equipment, and the effect of high surface activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

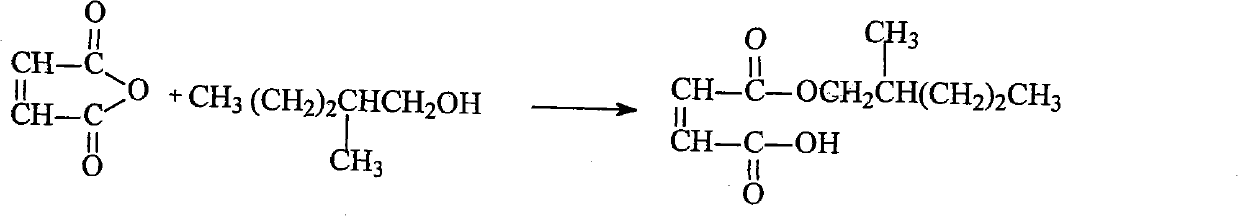

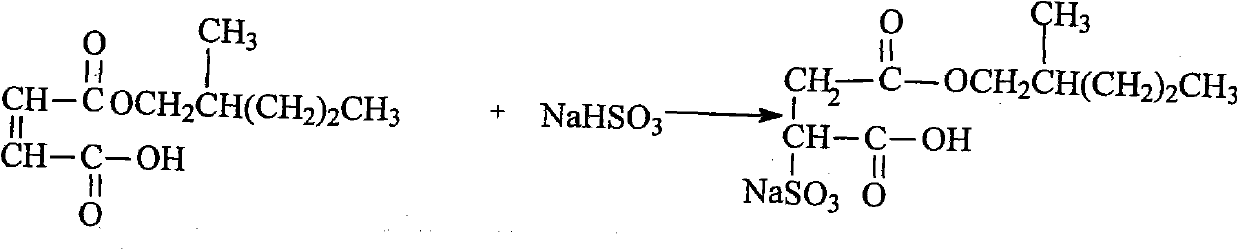

[0028] Monoesterification reaction: in a four-necked flask equipped with a stirrer, a thermometer and a reflux condenser, follow the ratio (molar ratio) of n (maleic anhydride): n (2-methyl-1-pentanol) = 1.05: 1.00 Add 2-methyl-1-pentanol, maleic anhydride and an alkylsulfonic acid catalyst accounting for 1% of the mass of maleic anhydride, feed nitrogen, stir and heat up to 80°C within 10 minutes; keep this temperature and time it, keep warm for 45 minutes, Production of monoesterification products. Sulfonation reaction: add sulfonating agent sodium bisulfite aqueous solution to the same reaction device, the molar ratio of the monoesterification product to the sulfur dioxide contained in the sulfonating agent is 1.00:1.10, and the sulfonation reaction is carried out under the protection of nitrogen atmosphere , start timing when the temperature rises to 70°C, the sulfonation reaction is completed at a temperature of 70-75°C after 120 minutes, and the sulfonation tail gas SO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com