Preparation method of polysaccharides from sea cucumber

A sea cucumber polysaccharide and sea cucumber technology, which is applied in the directions of antitoxin, blood diseases, extracellular fluid diseases, etc., can solve the problems of low product yield and purity, large amount of organic solvent, low purity, etc., so as to avoid the decrease of sea cucumber polysaccharide content. , The reaction conditions are easy to control, and the protein removal rate is high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

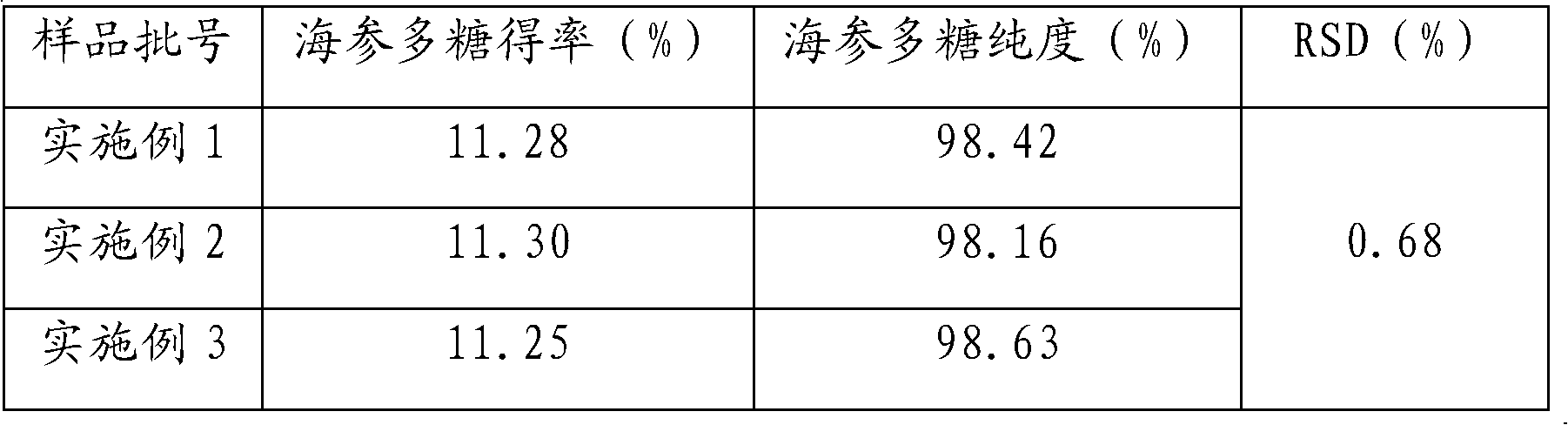

Embodiment 1

[0020] Grind 1.0kg of dried sea cucumber, add 2L of 2% sodium hydroxide solution twice the weight, stir and extract at room temperature for 2 hours, extract 2 times in total, filter, and combine to obtain 3.82L filtrate, cool the filtrate to room temperature, adjust When the pH value reaches 8.0, add 20ml of 2% trypsin (enzyme solution concentration 1mg / ml) and stir well, enzymolyze at 40°C for 2 hours, then adjust the pH value of the enzymolysis solution to 4.0 with 1% hydrochloric acid, and then add 2 % pepsin 20mL (enzyme solution concentration 1mg / ml), after enzymatic hydrolysis at 40°C for 2h, and then enzymatic passivation in boiling water at 100°C for 5min. After the enzymatic hydrolysis, use trichloroacetic acid to remove protein, add 10% trichloroacetic acid 10ml directly to the enzymolysis solution to adjust the pH to 3.0, and stir while adding to produce a precipitate, then place it at 4°C for 4 hours, and centrifuge to take the supernatant Solution 3.06L, add 2 tim...

Embodiment 2

[0022] Mince 1.5 kg of fresh sea cucumber, add 4 times the weight of 2% sodium hydroxide solution, stir and extract at room temperature for 3 hours, and filter; add 3 times the weight of 2% sodium hydroxide solution to the filter residue, stir and extract at room temperature for 4 hours, filter; combine twice Filtrate, get 4.13L filtrate, filtrate is cooled to room temperature, adjust pH value to 7.2 by adjusting 0.5% sulfuric acid solution, add 1% trypsin 30ml (enzyme solution concentration 1.5mg / ml) fully stir, at 36 ℃ enzymolysis 3 After 1 hour, adjust the pH value of the enzymolysis solution to 5.0 with 0.5% sulfuric acid, then add 30mL of 1.5% pepsin (enzyme solution concentration 1.4mg / ml), enzymolysis at 42°C for 1h, and then carry out in boiling water at 100°C Enzymatic passivation for 15 minutes. After the enzymolysis is complete, use trichloroacetic acid to remove protein, add about 15ml of 10% trichloroacetic acid directly to the enzymolysis solution to adjust the p...

Embodiment 3

[0024] Mince 2.0 kg of fresh sea cucumber, add 3 times the weight of 2% sodium hydroxide solution, stir and extract at room temperature for 4 hours, and filter; add 4 times the weight of 2% sodium hydroxide solution to the filter residue, stir and extract at room temperature for 2 hours, filter; combine twice Filtrate, get 5.25L filtrate, filtrate is cooled to room temperature, adjust pH value to 9.0 by adjusting 1% hydrochloric acid solution, add 3% trypsin 20ml (enzyme solution concentration 1.5mg / ml) fully stir, enzymolysis 4 at 50 ℃ After 1 hour, adjust the pH value of the enzymolysis solution to 6.0 with 1% hydrochloric acid, then add 20mL of 3% pepsin (enzyme solution concentration 1.4mg / ml), enzymolysis at 50°C for 1h, and then carry out in boiling water at 100°C Enzymatic passivation for 10 minutes. After the enzymolysis is complete, use trichloroacetic acid to remove protein, add about 15ml of 10% trichloroacetic acid directly to the enzymolysis solution to adjust the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com